Okay, here's how I'm going to approach this guide on work boot materials. First, I need to understand what's really being asked. They think they're asking about materials, but what they really want is a way to make the best possible choice for their specific situation, balancing safety, comfort, and cost-effectiveness. It's about making an informed decision, not just listing materials.

To do this, I need to be objective, clear, and authoritative, using language everyone can understand. The format has to be easily scannable with clear headings and short paragraphs. My goal is to synthesize the information, not regurgitate it.

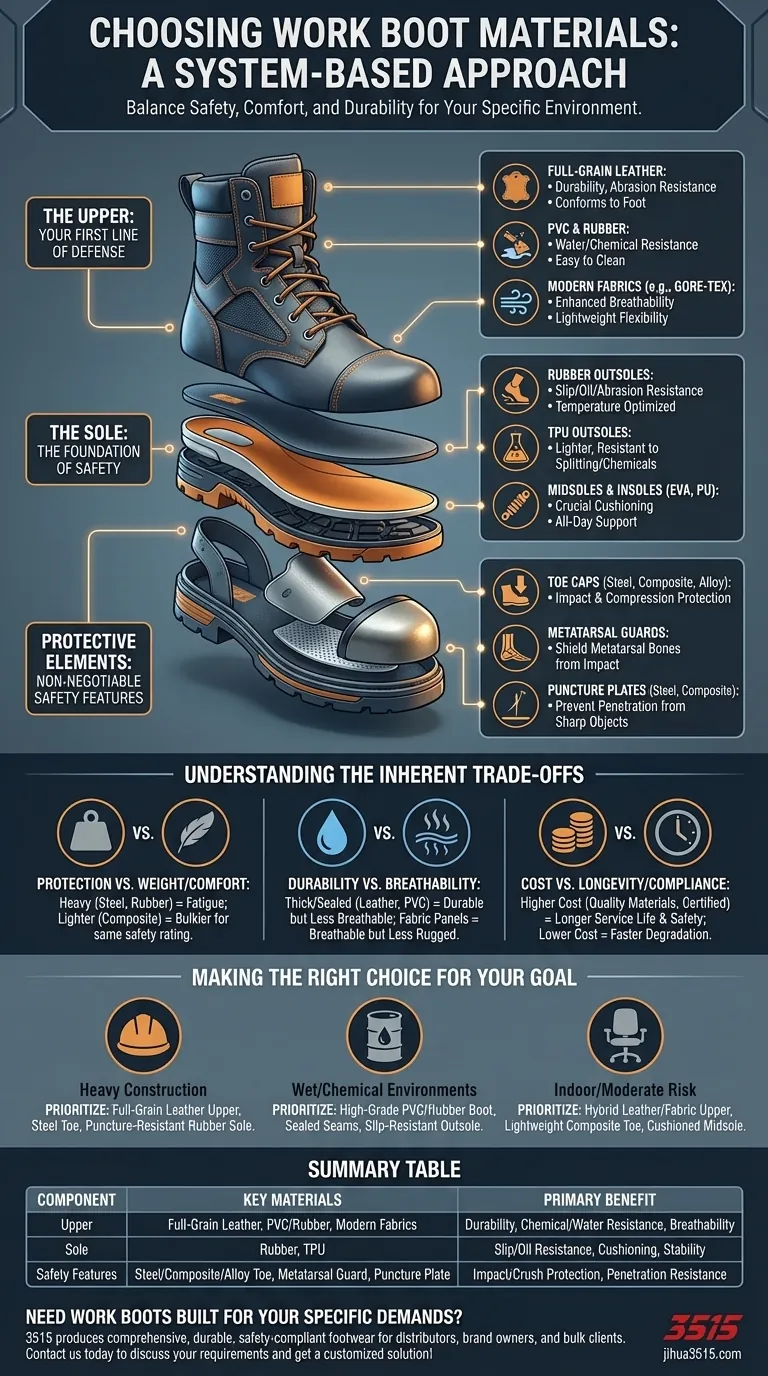

From the references, I've got a framework: the upper, the sole, and protective elements are key. I need to address the different materials (leather, rubber, PVC, Gore-Tex, etc.) within each of these. The key is to discuss the tradeoffs – protection vs. comfort, durability vs. breathability, cost vs. longevity.

The final piece will be actionable advice: recommendations based on different work environments. Heavy construction needs one thing; chemical environments something else. I'll make sure to end with a clear, empowering statement, leaving the reader confident in their ability to make the right choice. When choosing work boot materials, your decision must be based on a system, not a single component. The right choice involves balancing the materials of the upper, the sole, and the internal protective elements against the specific hazards and physical demands of your work environment. This ensures you get the protection you need without sacrificing necessary comfort or durability.

The most common mistake is focusing on a single material, like "leather" or "steel toe." The best work boot is a purpose-built system where the upper, sole, and safety components work together to meet the unique demands of your job.

Deconstructing the Work Boot: The Three Core Components

A work boot is not a single piece of material. To make an informed choice, you must evaluate the three distinct zones of its construction and how their materials align with your needs.

The Upper: Your First Line of Defense

The upper is the material covering your foot, providing the primary barrier against the elements.

- Full-Grain Leather: This is the traditional standard for durability and toughness. It offers excellent resistance to abrasion and provides natural breathability, conforming to your foot over time.

- PVC and Rubber: These synthetic materials are prized for their superior water and chemical resistance. They are ideal for wet environments or jobs involving hazardous liquids, and are often easier to clean.

- Modern Fabrics (e.g., Gore-Tex, Canvas): Specialized fabrics are often integrated into leather or synthetic boots. Their primary advantage is enhanced breathability and flexibility, reducing weight and improving comfort during long shifts.

The Sole: The Foundation of Safety

The outsole is your direct connection to the ground, critical for stability and protection from hazards underfoot.

- Rubber Outsoles: This is the go-to material for slip, oil, and abrasion resistance. Formulations can be optimized for specific conditions, such as high heat or extreme cold.

- TPU (Thermoplastic Polyurethane) Outsoles: TPU is a modern alternative that is often lighter than rubber and highly resistant to splitting, chemicals, and abrasion.

- Midsoles and Insoles: Often made of materials like EVA or PU, the midsole provides crucial cushioning and support. A quality midsole is as important for all-day comfort as the boot's fit.

The Protective Elements: Non-Negotiable Safety Features

These internal components are mandated for safety in hazardous environments.

- Reinforced Toe Caps: These protect your feet from compression and falling objects. Steel toes offer maximum protection but are heavy. Composite toes are lighter, don't conduct electricity, and don't get as cold, but are bulkier. Alloy toes offer a balance of lightweight and strong protection.

- Metatarsal Guards: These guards extend protection over the top of the foot, shielding the delicate metatarsal bones from impact.

- Puncture Plates: Often made of steel or composite materials, these are embedded in the midsole to prevent sharp objects like nails from penetrating the sole.

Understanding the Inherent Trade-offs

Selecting the right materials always involves balancing competing priorities. Understanding these trade-offs is key to avoiding a poor investment.

Protection vs. Weight and Comfort

The most protective features, like steel toes and thick rubber soles, add significant weight. This can lead to fatigue over a long day. Lighter options like composite toes may be more comfortable but can be bulkier to achieve the same safety rating.

Durability vs. Breathability

Thick, full-grain leather and waterproof PVC uppers offer maximum durability and protection from liquids. However, they are far less breathable than boots that incorporate nylon or canvas panels, which may be more comfortable in hot, dry conditions but offer less ruggedness.

Cost vs. Longevity and Compliance

High-grade materials and reputable construction methods cost more upfront. Cheaper boots may use lower-grade PVC that cracks or leather that quickly degrades. Investing in a boot with industry-standard certifications (like ASTM) and quality materials ensures both safety compliance and a longer service life.

Making the Right Choice for Your Goal

Your specific work environment is the ultimate guide. Use these scenarios to determine your primary material needs.

- If your primary focus is heavy construction or manufacturing: Prioritize a full-grain leather upper for durability, a steel toe for maximum impact protection, and a puncture-resistant rubber sole.

- If your primary focus is wet or chemical-heavy environments: Your best choice is a high-grade PVC or rubber boot with sealed seams and a certified, slip-resistant outsole.

- If your primary focus is long hours indoors with moderate risk: Look for a boot with a lightweight composite toe, a well-cushioned midsole, and a hybrid leather/fabric upper for breathability.

Choosing the right work boot is a critical investment in your daily safety and performance.

Summary Table:

| Component | Key Materials | Primary Benefit |

|---|---|---|

| Upper | Full-Grain Leather, PVC/Rubber, Modern Fabrics | Durability, Chemical/Water Resistance, Breathability |

| Sole | Rubber, TPU (Thermoplastic Polyurethane) | Slip/Oil Resistance, Cushioning, Stability |

| Safety Features | Steel/Composite/Alloy Toe, Metatarsal Guard, Puncture Plate | Impact/Crush Protection, Penetration Resistance |

Need work boots built for your specific demands? As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, tailored to your industry's needs. Contact us today to discuss your requirements and get a customized solution!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What does the 'PR' in ASTM F2413-18 M/I/C EH PR MT stand for? Decoding Your Boot's Safety Label

- What are the key differences between cowboy boots and Western work boots? Saddle vs. Ground Performance

- What are the best storage practices for fire boots? Keep Your Gear Ready & Extend Its Lifespan

- What should be considered when sizing and fitting engineer boots? Master the Laceless Fit for Maximum Comfort

- What are oilfield boots designed for? Unmatched Protection for Rig Workers

- What are moc toe boots and why are they popular? The Ultimate Guide to Rugged Style & Comfort

- What are the durability differences between low-pressure and high-pressure PU boots?

- What are the disadvantages of soft-toe boots? Understanding the Critical Safety Trade-Offs