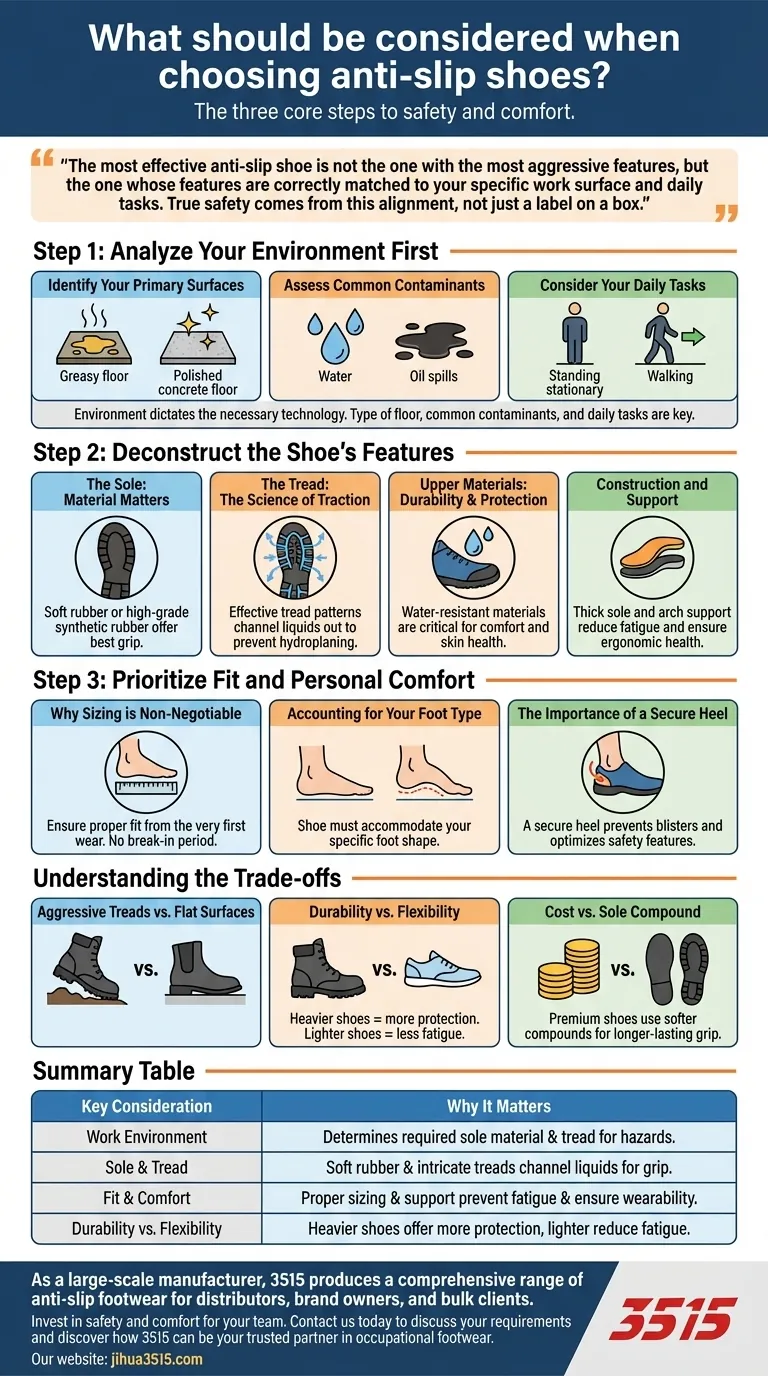

To choose the right anti-slip shoes, you must evaluate three core areas: the specific hazards of your work environment, the technical features of the shoe itself—primarily its sole material and tread pattern—and the personal requirements of fit and comfort for your feet.

The most effective anti-slip shoe is not the one with the most aggressive features, but the one whose features are correctly matched to your specific work surface and daily tasks. True safety comes from this alignment, not just a label on a box.

Step 1: Analyze Your Environment First

Before looking at any shoe, you must understand the specific challenges it needs to overcome. The environment dictates the necessary technology.

Identify Your Primary Surfaces

The type of floor you walk on is the single most important factor. A shoe designed for a greasy kitchen floor may not be optimal for a polished, wet concrete surface.

Assess Common Contaminants

Are you dealing with water, oil, grease, cleaning chemicals, or fine dust? Each substance interacts with a shoe's sole differently, and a tread pattern effective for water may not be effective for viscous oils.

Consider Your Daily Tasks

Do you stand in one place for hours, walk long distances, or frequently kneel and crouch? A heavy, durable shoe is great for stationary work but can cause fatigue for someone who is constantly moving.

Step 2: Deconstruct the Shoe's Features

Once you understand the environment, you can evaluate a shoe's technical specifications to see if it's a suitable match.

The Sole: Material Matters

The foundation of grip is the sole's material. Soft rubber or high-grade synthetic rubber soles generally offer the best traction because they can conform to microscopic imperfections in a floor surface.

The Tread: The Science of Traction

The pattern on the bottom of the shoe is engineered to provide stability. An effective tread will have numerous small, intricate patterns designed to channel liquids out from under the sole, preventing hydroplaning and maintaining contact with the floor.

Upper Materials: Durability and Protection

While the sole provides grip, the upper part of the shoe protects your foot. Look for water-resistant materials to keep your feet dry, which is critical for both comfort and preventing skin issues.

Construction and Support

A thick, durable sole does more than just grip; it provides essential support for your feet and back, reducing fatigue during long shifts. Proper arch support is also crucial for ergonomic health.

Step 3: Prioritize Fit and Personal Comfort

An ill-fitting safety shoe is both ineffective and dangerous. Unlike casual shoes, safety and work footwear do not "break in" over time.

Why Sizing is Non-Negotiable

You must ensure a proper fit from the very first wear. Measure both of your feet later in the day when they are slightly swollen. There should be enough room to wiggle your toes, and the width should be comfortable, not constricting.

Accounting for Your Foot Type

If you have flat feet or high arches, standard-issue arch support may be insufficient. The right shoe should accommodate your specific foot shape to prevent pain and fatigue.

The Importance of a Secure Heel

Your heel should not slip up and down as you walk. A secure fit prevents blisters and ensures your foot is properly positioned to benefit from the shoe's safety features.

Understanding the Trade-offs

There is no single "best" anti-slip shoe, only the best one for a specific job. Understanding the compromises is key to making an informed decision.

Aggressive Treads vs. Flat Surfaces

A shoe with a very deep, aggressive tread designed for uneven or debris-covered ground might feel unstable on a perfectly smooth, clean floor. The reduced surface contact can actually decrease grip in that specific context.

Durability vs. Flexibility

Heavier, more rigid shoes often provide maximum durability and protection. However, this comes at the cost of flexibility and can lead to faster fatigue for workers who need to be agile and are constantly in motion.

Cost vs. Sole Compound

Less expensive shoes may claim to be slip-resistant, but their soles are often made of a harder rubber compound that wears down quickly. A premium shoe uses a softer compound that maintains its grip for much longer, making it a better long-term investment in safety.

Making the Right Choice for Your Goal

Filter your options based on your most critical need.

- If your primary focus is a wet or oily kitchen/factory floor: Prioritize a soft rubber sole with an intricate, circular, or multi-directional tread pattern designed to channel liquids away effectively.

- If your primary focus is constant movement on varied surfaces: Seek a balance between a good tread pattern, a lightweight design, and excellent cushioning and arch support to minimize fatigue.

- If your primary focus is protection from impacts and spills: Ensure the shoe has a certified safety toe and durable, water-resistant upper materials in addition to its slip-resistant sole.

Ultimately, investing in the right footwear is a direct investment in your daily safety and long-term well-being.

Summary Table:

| Key Consideration | Why It Matters |

|---|---|

| Work Environment | Determines the required sole material and tread pattern for specific hazards (e.g., water, oil). |

| Sole & Tread | Soft rubber soles with intricate treads provide superior grip by channeling liquids away. |

| Fit & Comfort | Proper sizing and arch support are critical for preventing fatigue and ensuring long-term wearability. |

| Durability vs. Flexibility | Heavier shoes offer more protection, while lighter ones reduce fatigue for active roles. |

As a large-scale manufacturer, 3515 produces a comprehensive range of anti-slip footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the precise sole compounds and tread patterns your workforce needs. We ensure the perfect alignment between your specific environmental hazards and our footwear's technical features.

Invest in safety and comfort for your team. Contact us today to discuss your requirements and discover how 3515 can be your trusted partner in occupational footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture