When choosing snow boots, waterproofing is paramount. The key considerations are the fundamental difference between water-resistant and truly waterproof construction, the materials used for the sole and upper, the integrity of the seams, and whether the boot contains an internal waterproof membrane for guaranteed protection.

True waterproofing in a snow boot is not a single feature but a complete system. It relies on the synergy between outer materials, sealed construction, and an inner waterproof liner to keep your feet dry, comfortable, and safe in harsh winter conditions.

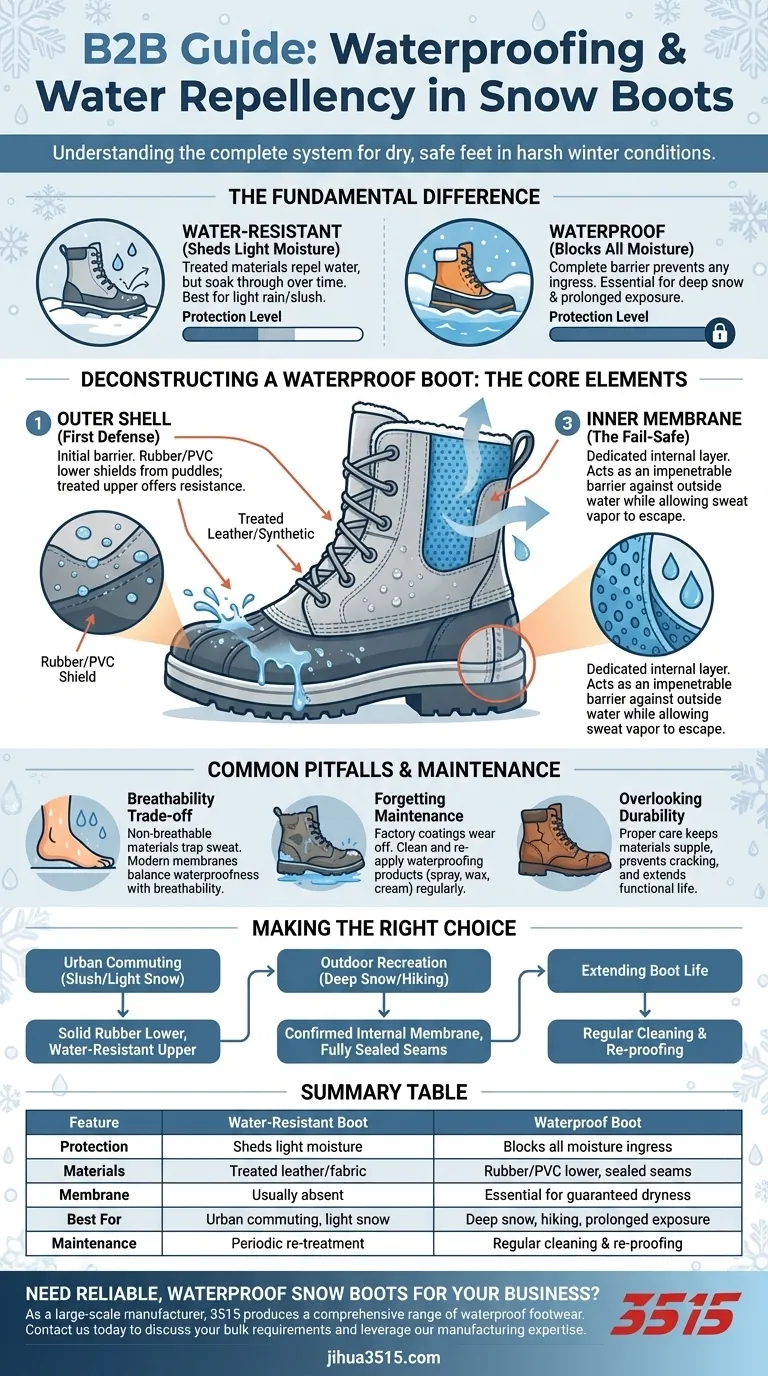

The Fundamental Difference: Waterproof vs. Water-Resistant

Your first decision point is understanding the level of protection you need, as the terms "water-resistant" and "waterproof" are not interchangeable.

Defining Water-Resistant

A water-resistant boot can shed light moisture from rain or shallow snow. Its materials are treated to repel water, but over time and with prolonged exposure, water will eventually soak through.

Defining Waterproof

A waterproof boot is designed to create a complete barrier, preventing any moisture from seeping in. This is essential for activities in deep snow, slush, or freezing rain where your feet will be constantly exposed to wetness.

Why Waterproofing is Non-Negotiable

Wet feet in cold temperatures are not just uncomfortable; they are dangerous. Moisture pulls heat away from the body rapidly, dramatically increasing the risk of discomfort, frostbite, and fungal infections. True snow boots are almost always waterproof for this reason.

Deconstructing a Waterproof Boot: The Core Elements

A boot's ability to keep water out depends on three interconnected components working together. A failure in any one area compromises the entire system.

The Outer Shell (The First Defense)

The exterior materials provide the initial barrier. Most snow boots feature a lower section and sole made of completely waterproof materials like rubber or PVC, which act as a shield when walking through puddles or slush. The upper portion of the boot is typically made of treated leather or synthetic fabrics that offer water resistance.

The Construction (The Weakest Link)

A boot is only as waterproof as its seams. Look for boots with sealed seams or a direct-attached sole with a waterproof seal. If a sole is sewn on, the stitching itself must be waterproof to prevent it from becoming a point of entry for moisture.

The Inner Membrane (The Fail-Safe)

The most reliable feature of a high-quality waterproof boot is an internal waterproof membrane or liner. This is a dedicated layer built inside the boot that acts as a final, impenetrable barrier, ensuring your feet stay dry even if the outer materials become saturated.

Common Pitfalls to Avoid

Understanding the limitations and potential points of failure will help you make a more informed decision and properly care for your investment.

The Breathability Trade-off

The most waterproof material, like solid rubber, is not breathable. This can trap sweat, making your feet damp from the inside. Modern waterproof membranes are designed to be breathable, allowing water vapor (sweat) to escape while blocking liquid water from entering.

Forgetting About Maintenance

The factory-applied water-repellent coating on a boot's exterior will wear off over time. You must maintain this outer layer's performance by cleaning the boots and periodically re-applying a suitable waterproofing product like a spray, wax, or cream.

Overlooking Long-Term Durability

Proper maintenance, especially for leather boots, does more than just repel water. It keeps the material supple, prevents it from drying out and cracking, and significantly extends the functional life of the boot.

Making the Right Choice for Your Needs

Use your primary activity as the guide to determine the level of protection you require.

- If your primary focus is daily urban commuting in slush and light snow: A boot with a solid rubber lower shell and a well-treated, water-resistant upper is often sufficient.

- If your primary focus is outdoor recreation in deep snow (hiking, shoveling): Prioritize boots with a confirmed internal waterproof membrane and fully sealed seams for guaranteed dryness.

- If your primary focus is extending the life of your current boots: Regularly clean them and re-apply a waterproofing treatment appropriate for the outer material to maintain their first line of defense.

Choosing the right boot means understanding that true dryness comes from a well-engineered system, not just a single feature.

Summary Table:

| Feature | Water-Resistant Boot | Waterproof Boot |

|---|---|---|

| Protection Level | Sheds light moisture | Blocks all moisture ingress |

| Key Materials | Treated leather/fabric | Rubber/PVC lower, sealed seams |

| Internal Membrane | Usually absent | Essential for guaranteed dryness |

| Best For | Urban commuting, light snow | Deep snow, hiking, prolonged exposure |

| Maintenance | Periodic re-treatment | Regular cleaning and re-proofing |

Need Reliable, Waterproof Snow Boots for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of waterproof footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable snow boots, featuring sealed seams, high-quality materials, and advanced waterproof membranes to ensure complete customer satisfaction and safety in harsh conditions.

Contact 3515 today to discuss your bulk snow boot requirements and leverage our manufacturing expertise for your market.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How can customer reviews help when buying winter boots? Uncover Real-World Performance & Avoid Costly Mistakes

- Why is weight an important factor for comfort in winter boots? Find the Perfect Balance for All-Day Wear

- How do snow boots differ from winter boots? Choose the Right Footwear for Your Winter

- What features make tall snow boots suitable for winter conditions? Stay Warm, Dry & Secure in Deep Snow

- What care tips should be followed for synthetic motorcycle boots? A Simple Guide to Long-Lasting Protection

- What should be considered when choosing footwear for snowy conditions? Ensure Comfort and Safety

- What features are important in the lower boot design? A Guide to Rider Control and Safety

- What types of solid-colored boots do hunters recommend? Top Picks for Stealth & Versatility