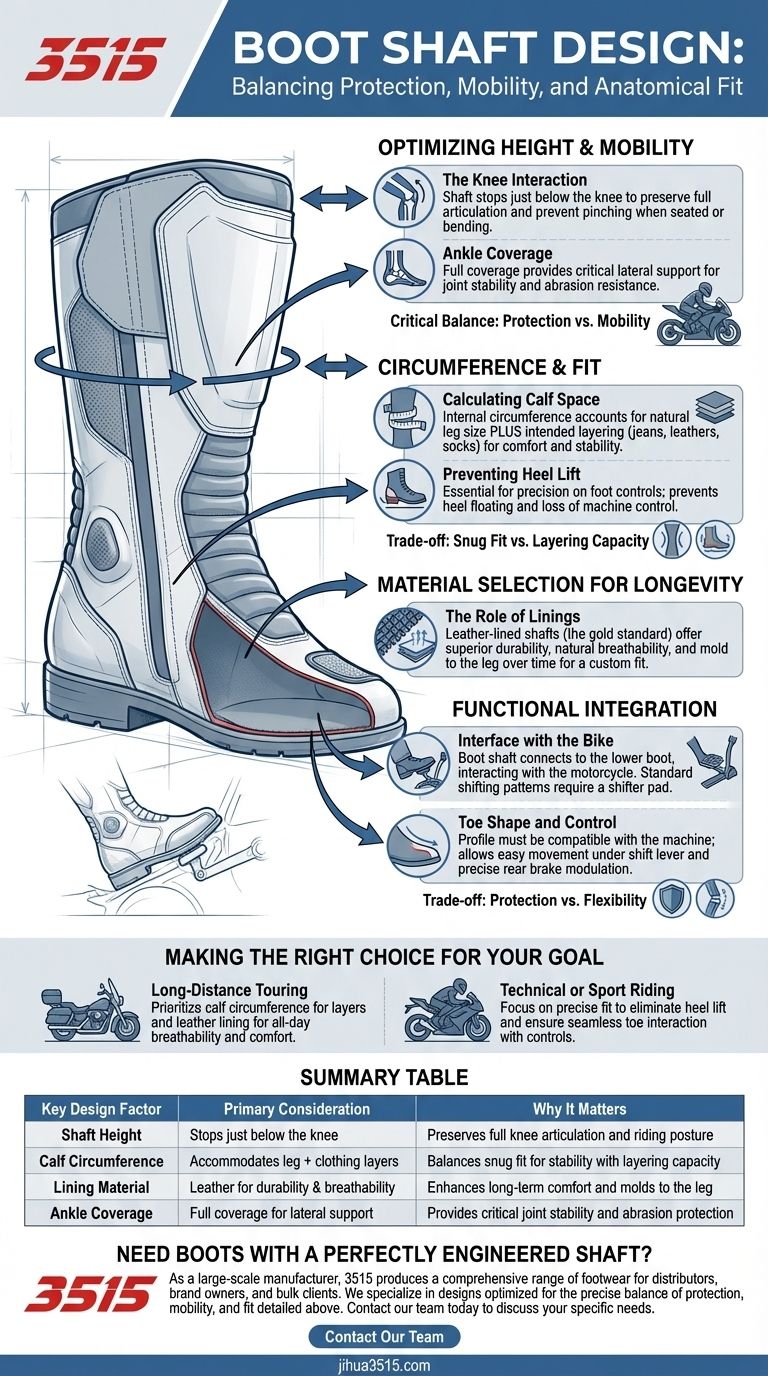

Boot shaft design is a critical balance of protection, mobility, and anatomical fit. To ensure the boot functions correctly, you must evaluate four primary variables: ankle coverage for structural stability, lining material for internal climate control, shaft height to preserve knee articulation, and calf circumference to accommodate layering without restricting circulation.

The shaft's mechanical function is to stabilize the ankle and protect the lower leg without compromising the rider's ability to operate foot controls or articulate the knee.

Optimizing Height and Mobility

The Knee Interaction

The vertical limit of the shaft is a crucial ergonomic factor. The shaft should generally stop just below the knee.

This clearance prevents the top of the boot from pinching or restricting the joint. It ensures you maintain full range of motion when seated on the bike or bending your legs.

Ankle Coverage

At the lower end of the shaft, the design must fully cover the ankles.

This is not merely for abrasion resistance. Proper coverage provides the lateral stability required to support the joint during a ride or in the event of a mishap.

The Importance of Circumference and Fit

Calculating Calf Space

The internal circumference of the shaft must be calculated based on your specific anatomy plus your gear.

You must account for your natural leg size as well as the thickness of any clothing (jeans, leathers, or socks) you intend to tuck inside. A shaft that is too narrow will be uncomfortable, while one that is too wide offers insufficient stability.

Preventing Heel Lift

While technically a function of the lower boot, the shaft contributes to securing the foot.

A proper fit is essential to prevent heel lift. If the heel floats inside the boot, you lose precision on the pegs and controls, reducing your overall control of the machine.

Material Selection for Longevity

The Role of Linings

The material inside the shaft dictates the long-term comfort of the boot.

Leather-lined shafts are the gold standard referenced for high-quality construction. They offer superior durability compared to synthetics. Furthermore, leather provides natural breathability and molds to the leg over time for a custom fit.

Functional Integration with Controls

Interface with the Bike

The boot shaft does not exist in a vacuum; it connects to the lower boot which interacts with the motorcycle.

For riders using standard shifting patterns, a shifter pad is essential to protect the toe box from premature wear. However, if you utilize a heel-toe shifter, this feature becomes less critical.

Toe Shape and Control

The profile of the toe box must be compatible with your specific machine.

The toe shape should allow for easy movement under the shift lever and precise modulation of the rear brake. A bulky toe box can make shifting clumsy, while a profile that is too slim may offer inadequate protection.

Understanding the Trade-offs

Protection vs. Flexibility

There is an inherent tension between a protective high shaft and mobility.

A taller shaft offers more shin protection and element exclusion. However, if the height is not measured precisely to stop below the knee, it becomes a major hindrance to riding posture.

Snug Fit vs. Layering Capacity

Choosing a shaft circumference involves a compromise on versatility.

A shaft fitted tightly to the leg offers the best stability and fits easily under pants. However, it eliminates the ability to tuck in heavier trousers or winter layers, potentially limiting the boot's utility in colder weather.

Making the Right Choice for Your Goal

To select the correct boot shaft design, assess your primary riding environment:

- If your primary focus is Long-Distance Touring: Prioritize a calf circumference that accommodates layers and a leather lining for maximum breathability and comfort over long hours.

- If your primary focus is Technical or Sport Riding: Focus on a precise fit that eliminates heel lift and ensures the toe shape interacts seamlessly with your specific bike's controls.

The ideal boot shaft provides structural support you can trust while remaining comfortable enough to be forgotten.

Summary Table:

| Key Design Factor | Primary Consideration | Why It Matters |

|---|---|---|

| Shaft Height | Stops just below the knee | Preserves full knee articulation and riding posture |

| Calf Circumference | Accommodates leg + clothing layers | Balances snug fit for stability with layering capacity |

| Lining Material | Leather for durability & breathability | Enhances long-term comfort and molds to the leg |

| Ankle Coverage | Full coverage for lateral support | Provides critical joint stability and abrasion protection |

Need boots with a perfectly engineered shaft?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including designs optimized for the precise balance of protection, mobility, and fit detailed above.

We can help you develop or source boots that provide the structural support riders trust. Contact our team today to discuss your specific needs.

Visual Guide

Related Products

- Wholesale Durable 6-Inch Work Boots | Custom & Private Label Manufacturer

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- Which types of shoes should be avoided with business casual attire? Maintain a Polished Professional Image

- What role does PET bottle recycling technology play in the footwear industry? Driving Circularity & Performance

- What advantages does a voice command module provide for user interaction in smart assistive footwear? Elevate Navigation & Safety

- What are the different finishes applied to leather? A Guide to Aniline, Pigmented & More

- Are thermal booties more effective than toe covers? The Ultimate Guide to Warm Feet on Cold Rides

- What shoe styles are best for narrow feet? Find a Secure, Customized Fit for Slender Feet

- What is the significance of a Pilot Testing Plant? Bridging Footwear Innovation and Mass Production Success

- How can riders ensure proper boot fit and comfort? A Guide to Snug, Secure, and Pain-Free Riding