At their core, sharp materials and tools in the workplace pose a direct and severe risk of puncture wounds, lacerations, and cuts to a worker's feet. Steel toe shoes directly mitigate these dangers by incorporating a reinforced protective cap and durable outer materials that serve as a physical barrier, deflecting or stopping sharp objects before they can cause injury.

The true value of steel toe footwear is not just in protecting against a single hazard, but in providing comprehensive defense against the most common and debilitating foot injuries found in hazardous environments—from punctures and cuts to impacts and compression.

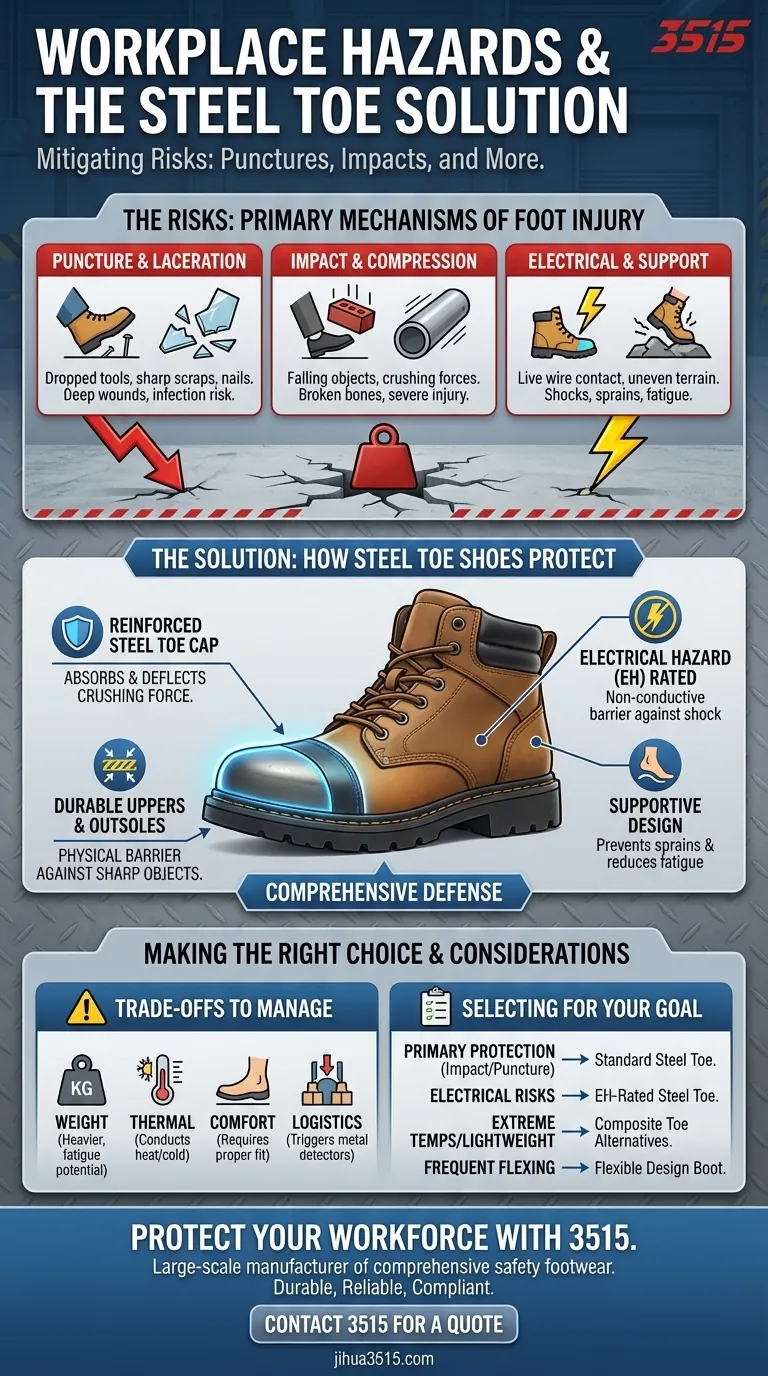

The Primary Mechanisms of Foot Injury

To understand the solution, we must first define the distinct problems. Foot injuries in industrial or construction environments typically fall into several key categories.

Puncture and Laceration Risks

Dropped tools, exposed nails, sharp metal scraps, or glass can easily pierce standard footwear. This leads to deep puncture wounds, which carry a high risk of infection, or severe cuts (lacerations) that can damage tendons and tissue.

Impact and Compression

Heavy objects falling from a height create a high-impact force concentrated in a small area. Similarly, rolling objects like pipes or heavy carts can create a crushing or compression force. Both can result in broken bones and catastrophic injury to the toes and forefoot.

Electrical and Support Hazards

Beyond physical impacts, worksites present other dangers. Contact with a live wire can cause a severe electrical shock. Furthermore, long hours on uneven surfaces can lead to sprains and strains without proper footwear support.

How Steel Toe Shoes Provide Comprehensive Protection

Steel toe footwear is an engineered solution designed to counter the specific hazards of demanding work environments. Its protective qualities come from several key components working in unison.

The Reinforced Steel Toe Cap

This is the most well-known feature. A cap made of heavy-duty steel is built into the front of the shoe, directly over the toes. This component is specifically designed to withstand immense impact and compression forces, protecting the most vulnerable bones in the foot from falling or rolling objects.

Durable Uppers and Outsoles

While the toe cap guards against impacts from above, the rest of the shoe provides crucial protection. Tough materials like thick leather and puncture-resistant soles prevent sharp objects on the ground from piercing the foot from below, directly addressing the risk of punctures.

Specialized Protective Features

Modern safety shoes often include additional features. Many are rated as non-conductive, providing a barrier against electrical shock from live wires. They also offer built-in ankle and arch support, which helps prevent sprains and fatigue during long workdays.

Understanding the Trade-offs

While essential, steel toe footwear is a specialized tool with inherent trade-offs that are important to acknowledge for proper selection and use.

Increased Weight

The primary disadvantage is weight. The steel component adds significant heft compared to standard boots or even composite-toe alternatives, which can contribute to fatigue over a long shift.

Thermal Conductivity

Steel is an excellent conductor of temperature. This makes traditional steel toe boots poorly suited for extremely cold or hot environments, as the cap can become uncomfortably cold or hot to the touch.

Potential for Discomfort

If not fitted properly, the rigid nature of the steel cap can cause discomfort or rubbing, especially during a break-in period. A proper fit is non-negotiable for all-day wear.

Logistical Issues

In certain environments, the steel will reliably trigger metal detectors. This can be a minor but consistent inconvenience for workers who must pass through security checkpoints frequently.

Making the Right Choice for Your Goal

Selecting the appropriate foot protection requires matching the shoe's features to the specific hazards of your work environment.

- If your primary focus is protection from falling objects and punctures: A standard steel toe boot is the industry benchmark for construction, manufacturing, and warehouse roles.

- If you work around live electrical currents: You must select steel toe footwear that is explicitly rated as non-conductive or "EH" (Electrical Hazard).

- If you work in extreme temperatures or need a lighter boot: Consider composite toe alternatives, which provide protection without the thermal conductivity and weight of steel.

- If your work involves frequent kneeling or flexing: Ensure the boot is designed for flexibility to avoid discomfort from the rigid toe cap.

Choosing the correct safety footwear is a foundational step in ensuring personal safety and preventing injury on any job site.

Summary Table:

| Hazard Type | Risk to Worker | How Steel Toe Shoes Mitigate Risk |

|---|---|---|

| Puncture/Laceration | Deep wounds from nails, glass, sharp metal | Puncture-resistant soles and durable uppers act as a barrier |

| Impact/Compression | Broken bones from falling/rolling heavy objects | Reinforced steel toe cap absorbs and deflects crushing force |

| Electrical Hazard | Severe shock from contact with live wires | Non-conductive (EH-rated) materials provide a safety barrier |

| Support Hazard | Sprains, strains, and fatigue from long hours | Built-in ankle and arch support enhances stability and comfort |

Protect your workforce with the right safety footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of steel toe and safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective shoes and boots, designed to meet the highest safety standards for any industrial environment.

Let us help you equip your team with durable, reliable, and compliant footwear that reduces workplace injuries and boosts productivity.

Contact 3515 today for a quote and discover the perfect safety solution for your business.

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- Why are safety shoes with slip-resistant soles essential for basement construction? Prevent falls on mossy surfaces.

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures

- What role do high-sensitivity IoT devices play in footwear material handling? Powering Green Logistics & Efficiency

- Why is specialized personal protective equipment required for specific industries? Enhancing Safety in Heavy Industry

- What impact do steel toe caps have on toe skin health? Prevent Friction and Pressure in Your Safety Shoes