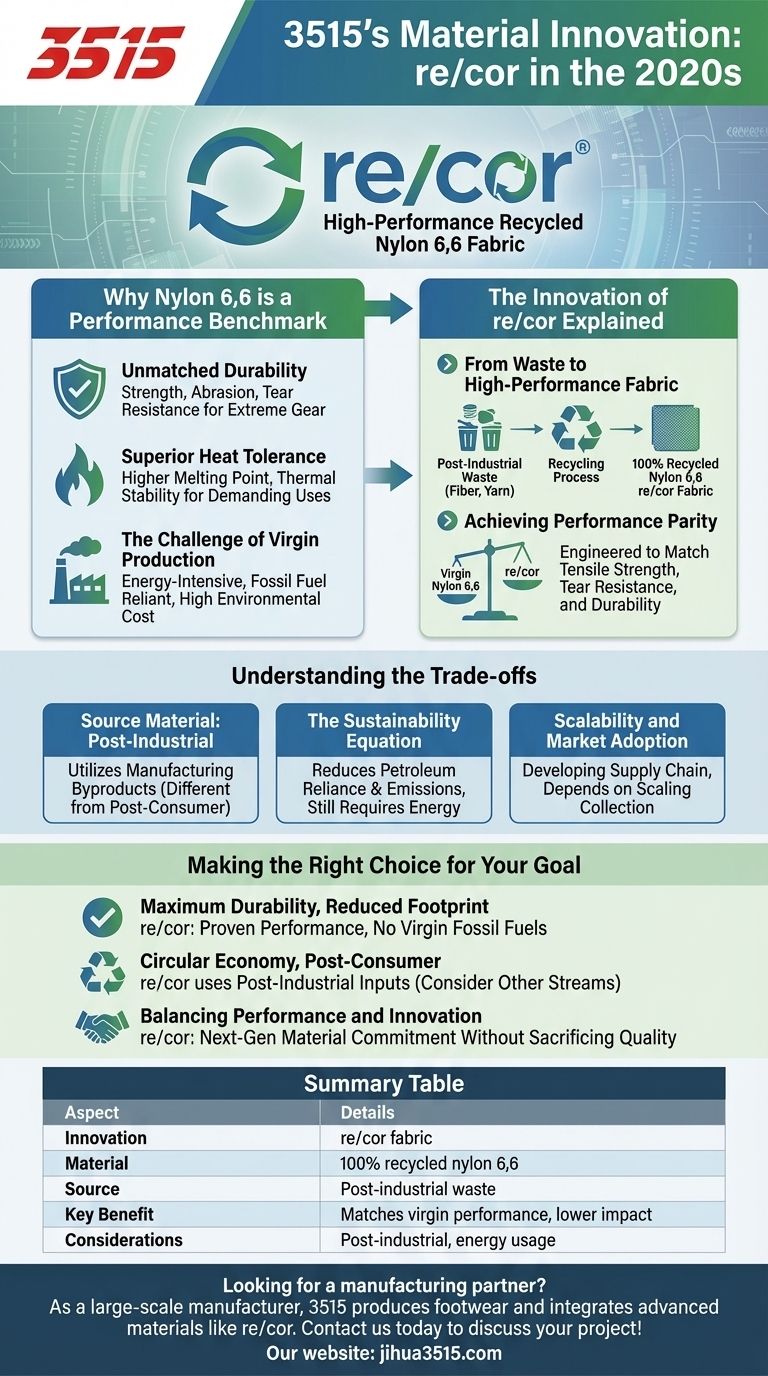

In the 2020s, the brand's most significant material innovation is re/cor. This is a high-performance, recycled nylon 6,6 fabric developed to meet the growing industry demand for materials that offer exceptional durability without the environmental footprint of virgin synthetics.

The introduction of re/cor signals a pivotal shift in material science: proving that recycled content does not have to mean a compromise in the high-tenacity performance that defines technical fabrics. It directly addresses the challenge of making one of the industry's most trusted materials more sustainable.

Why Nylon 6,6 is a Performance Benchmark

To understand the importance of a recycled version, one must first appreciate why virgin nylon 6,6 is the gold standard for demanding applications. Its molecular structure gives it inherent advantages.

Unmatched Durability and Abrasion Resistance

Nylon 6,6 is renowned for its exceptional strength and resistance to tearing and abrasion. This makes it the default choice for gear that must withstand extreme friction and stress, like backpacks and outerwear.

Superior Heat Tolerance

Compared to other common nylons (like nylon 6), nylon 6,6 has a higher melting point and better thermal stability. This property is critical for applications where materials are exposed to heat during use or production processes like dyeing.

The Challenge of Virgin Production

The strength of nylon 6,6 comes at an environmental cost. Its production is an energy-intensive process that relies on fossil fuel feedstocks, making the development of a viable recycled alternative a top priority for sustainable design.

The Innovation of re/cor Explained

re/cor is not just another recycled fabric; it is a specific solution engineered to replace virgin nylon 6,6 without a drop in performance.

From Waste to High-Performance Fabric

The re/cor fabric is created using 100% recycled nylon 6,6 sourced from post-industrial waste. This includes fiber and yarn waste from manufacturing facilities, diverting it from landfills.

Achieving Performance Parity

The primary technical goal of re/cor was to match the performance characteristics of its virgin counterpart. This means it is engineered to deliver the same level of tensile strength, tear resistance, and durability that designers and users expect.

Understanding the Trade-offs

Adopting any new material requires an objective look at its context and limitations. While re/cor is a major step forward, there are important considerations.

Source Material: Post-Industrial vs. Post-Consumer

The current re/cor material is made from post-industrial waste. While this is an excellent use of manufacturing byproducts, it is different from post-consumer waste (like old carpets or apparel), which presents a more complex recycling challenge.

The Sustainability Equation

Recycling nylon 6,6 significantly reduces reliance on petroleum and lowers greenhouse gas emissions compared to virgin production. However, the recycling process itself still requires energy and resources. It is a step-change improvement, not a zero-impact solution.

Scalability and Market Adoption

As a newer innovation, the supply chain for recycled nylon 6,6 is still developing. Widespread adoption depends on the industry's ability to scale collection and reprocessing of compatible waste streams effectively.

Making the Right Choice for Your Goal

Evaluating re/cor depends entirely on your project's specific priorities.

- If your primary focus is maximum durability with a reduced environmental footprint: re/cor is a premier choice, as it maintains the proven performance of nylon 6,6 while cutting ties to virgin fossil fuels.

- If your primary focus is a circular economy using post-consumer goods: You must note that re/cor utilizes post-industrial inputs, and other material streams may be more aligned with a post-consumer recycling mandate.

- If your primary focus is balancing performance and innovation: Integrating re/cor demonstrates a commitment to next-generation materials without sacrificing the quality and reliability your users depend on.

By understanding the technical and environmental context of re/cor, you can make a truly informed decision for your specific application.

Summary Table:

| Aspect | Details |

|---|---|

| Innovation | re/cor fabric |

| Material | 100% recycled nylon 6,6 |

| Source | Post-industrial waste |

| Key Benefit | Matches virgin nylon 6,6 performance with lower environmental impact |

| Considerations | Uses post-industrial, not post-consumer, waste; process still requires energy |

Looking for a manufacturing partner to bring your innovative product ideas to life?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, and we are adept at integrating advanced materials like re/cor to meet your performance and sustainability goals.

Let's collaborate to create high-quality, durable products that stand out in the market. Contact us today to discuss your project!

Visual Guide

Related Products

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

People Also Ask

- What concerns are raised about using boots? Managing Heat and Pressure Risks for Horse Legs

- Why does industrial footwear design for elderly users emphasize a rigid heel counter? Essential Stability & Safety

- How do real-world accidents prove motorcycle boot effectiveness? Avoid Life-Altering Injuries

- Why is using brushes or scrapers for adhesive application safer than manual hand application? Protect Your Workers Now

- What are the key features of off-road and motocross motorcycle boots? Essential Protection for Demanding Rides

- How do predictive maintenance systems ensure operational efficiency? Optimize Your Footwear Production Line Today

- How does a specialized axial loading device ensure the accuracy of biomechanical simulations? Precision Testing Guide

- What is the necessity of performing multi-point inspections on shoe soles? Ensure Consistency and Safety