At its core, the vast range of modern fabrics is built upon three fundamental construction methods: weaving, knitting, and non-woven bonding. While material choices like high-tenacity polyester or ultra-lightweight nylon define a fabric's chemical properties, it is the construction method that dictates its essential mechanical behavior, such as its stability, stretch, and drape.

The choice between a woven, knit, or non-woven structure is the primary decision that governs a fabric's performance. This structural choice is more fundamental than the fiber type itself and is the key to selecting the right material for your application.

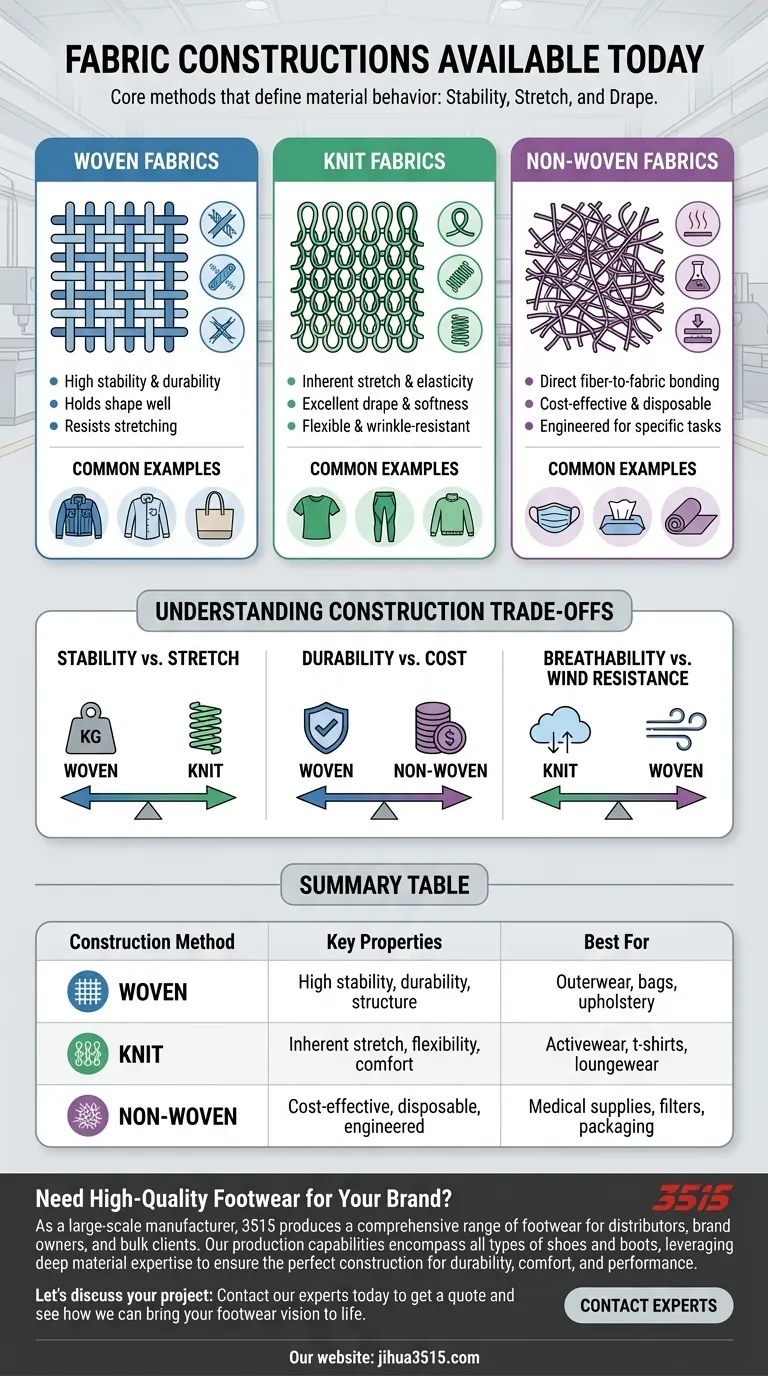

Woven Fabrics: The Foundation of Stability

Woven fabrics are the most traditional and widely understood category. They are created by the systematic interlacing of two sets of yarns.

How Weaving Works

Weaving involves arranging one set of yarns, called the warp, to run lengthwise, while a second set, the weft, is interlaced across them at a 90-degree angle. This grid-like structure is what gives woven fabrics their characteristic properties.

Key Properties

The tight, interlocking grid makes woven fabrics exceptionally stable and durable. They resist stretching along their length and width and tend to hold their shape well, making them ideal for applications requiring structure.

Common Examples

The specific pattern of interlacing creates different types of weaves. The most common are plain weave (e.g., poplin, muslin), twill weave (e.g., denim, chino), and satin weave (e.g., satin, sateen), each offering a unique balance of smoothness, durability, and drape.

Knit Fabrics: Engineered for Flexibility

Knit fabrics are constructed from a single yarn or a set of yarns formed into a series of interlocking loops. This structure is fundamentally different from the rigid grid of a woven fabric.

How Knitting Works

Instead of crisscrossing yarns, knitting continuously loops a yarn through previous loops. This process creates a material that is inherently flexible and can move with the body.

Key Properties

The looped structure gives knit fabrics their signature stretch and elasticity, even when made from non-stretch fibers. They are also known for their excellent drape, softness, and wrinkle resistance, making them a top choice for comfortable apparel.

Common Examples

There are two main categories of knits. Weft knits, like the jersey used in T-shirts, are made from a single yarn running crosswise. Warp knits, like the tricot used in lingerie and athletic wear, are made from multiple parallel yarns, making them more run-resistant.

Non-Woven Fabrics: Direct Fiber-to-Fabric

Non-wovens represent a modern, engineered approach to fabric creation that bypasses the need for yarns entirely.

How Non-Wovens are Made

These fabrics are created by taking a mass of fibers and bonding them together directly. This bonding can be achieved through thermal (heat), chemical (adhesives), or mechanical (pressure and entanglement) processes.

Key Properties

Non-wovens are typically very cost-effective and can be engineered for specific tasks, such as high absorbency or water repellency. However, they generally lack the strength, drape, and durability of their woven or knit counterparts.

Common Examples

You encounter non-wovens every day in products like disposable medical masks, cleaning wipes, garment interfacings, and geotextiles used in construction.

Understanding the Construction Trade-offs

Choosing a fabric construction always involves balancing competing priorities. No single method is universally superior; the best choice depends entirely on the end-use requirements.

Stability vs. Stretch

This is the most critical trade-off. Woven fabrics offer superior dimensional stability, making them ideal for structured items like tailored suits or upholstery. Knit fabrics provide inherent stretch and recovery, essential for form-fitting garments and activewear.

Durability vs. Cost

Woven fabrics generally offer high durability and abrasion resistance due to their tight, interlocked structure. Non-woven fabrics, while less durable, can be produced at a fraction of the cost, making them perfect for single-use or disposable applications.

Breathability vs. Wind Resistance

The looped structure of knits naturally creates small air pockets, leading to excellent breathability. In contrast, a tightly packed woven fabric creates a formidable barrier to wind, a key reason it is used for outerwear and flags.

Selecting the Right Construction for Your Application

Your final decision should be guided by the primary performance requirement of your product.

- If your primary focus is durability and structure (e.g., outerwear, bags, upholstery): Woven construction is the definitive choice for its dimensional stability and strength.

- If your primary focus is comfort, stretch, and movement (e.g., activewear, t-shirts, loungewear): Knit construction provides the ideal flexibility and drape for garments worn close to the body.

- If your primary focus is disposability, filtration, or cost-effectiveness (e.g., medical supplies, packaging, filters): Non-woven construction offers an engineered and economical solution.

Understanding these three core construction methods empowers you to select the perfect fabric foundation for any project.

Summary Table:

| Construction Method | Key Properties | Best For |

|---|---|---|

| Woven | High stability, durability, structure | Outerwear, bags, upholstery |

| Knit | Inherent stretch, flexibility, comfort | Activewear, t-shirts, loungewear |

| Non-Woven | Cost-effective, disposable, engineered | Medical supplies, filters, packaging |

Need High-Quality Footwear for Your Brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, leveraging deep material expertise to ensure the perfect construction for durability, comfort, and performance.

Let's discuss your project: Contact our experts today to get a quote and see how we can bring your footwear vision to life.

Visual Guide

Related Products

People Also Ask

- Why is rubber commonly used for non-slip soles? The Science of Superior Grip

- What should be avoided when storing boots with outsoles? Protect Your Investment from Dry Rot & Decay

- What are the advantages of rubber soles in safety boots? Unbeatable Grip & Durability

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- Why are rubber soles beneficial in cold-weather boots? Superior Traction & Waterproofing