At its core, a shoe qualifies as slip-resistant based on the specific design of its outsole, which is engineered to maximize friction and maintain grip on slick surfaces. This is achieved through a combination of specialized tread patterns that channel away liquids, deep grooves that increase surface contact, and advanced rubber compounds that provide superior traction compared to standard footwear.

The defining characteristic of a truly slip-resistant shoe is not a single feature, but a purpose-built system. The outsole's material, tread pattern, and groove depth work together to actively displace liquids and maximize the shoe's grip on the ground.

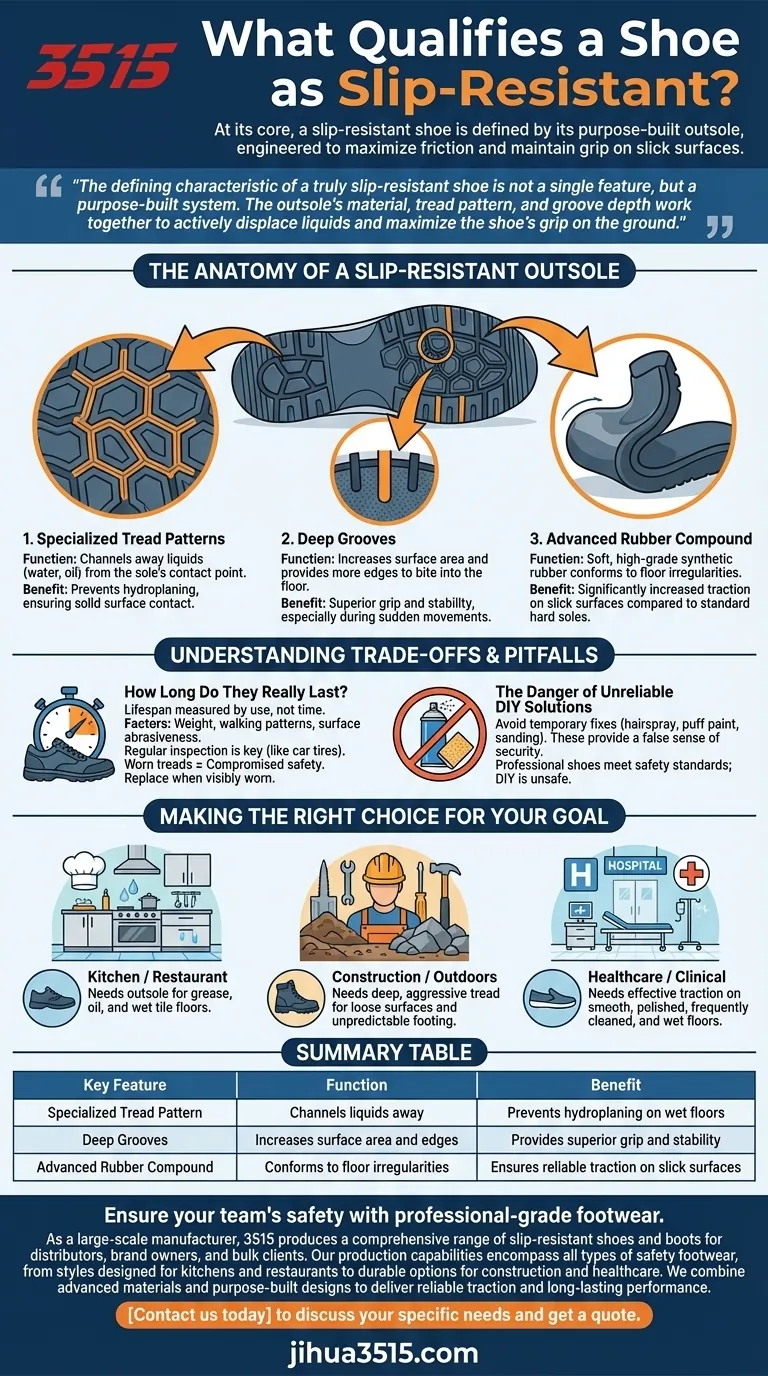

The Anatomy of a Slip-Resistant Outsole

A shoe's ability to prevent slips is determined almost entirely by the science of its outsole. Three key design features are responsible for creating reliable traction.

The Critical Role of Tread Patterns

The specific shapes on the bottom of the shoe are its first line of defense. Outsoles often feature interlocked patterns of small hexagons or circles.

This design is not for aesthetics; it creates a network of channels that efficiently direct water, oil, and other liquids away from the sole's point of contact with the floor. By clearing the liquid, the sole can make solid contact with the surface.

The Importance of Groove Depth

In addition to the pattern, the depth of the grooves is essential. Deeper grooves create more edges and a larger effective surface area to bite into the floor.

This increased friction is what provides a secure and stable grip, especially when changing direction or stopping suddenly on a compromised surface.

The Superiority of Specific Materials

The material of the outsole itself is a fundamental component. Slip-resistant shoes typically use a soft, high-grade synthetic rubber compound.

Unlike the harder, less pliable soles of standard shoes, this soft rubber is able to conform more closely to microscopic irregularities in a floor's surface, significantly increasing traction.

Understanding the Trade-offs and Common Pitfalls

While essential for safety, slip-resistant shoes are specialized equipment. Understanding their limitations is key to using them effectively.

How Long Do They Really Last?

The lifespan of a slip-resistant sole is not measured in months or years, but in use. Factors like your body weight, walking patterns, and the abrasiveness of the surfaces you walk on all contribute to wear.

It's better to inspect the tread depth regularly, much like you would with car tires. Once the patterns are visibly worn down, the shoe's safety features are compromised and it's time for a replacement.

The Danger of Unreliable DIY Solutions

Some sources suggest temporary fixes like hairspray, puff paint, or scoring the soles with sandpaper. These methods are unreliable and provide a false sense of security.

A professionally designed slip-resistant shoe is tested to meet specific safety standards. DIY alterations are not a safe or acceptable substitute for proper, purpose-built footwear in a hazardous environment.

Making the Right Choice for Your Goal

The right shoe depends entirely on the environment where you'll be wearing it. Assess your specific needs before making a choice.

- If your primary focus is a kitchen or restaurant environment: You need a shoe with an outsole specifically designed to handle grease, oil, and wet tile floors.

- If your primary focus is construction or uneven outdoor terrain: You need a durable shoe with a deep, aggressive tread pattern designed for loose surfaces and unpredictable footing.

- If your primary focus is a healthcare or clinical setting: You need a shoe with effective traction on smooth, polished floors that are frequently cleaned and may be wet.

Ultimately, choosing the right footwear is a critical decision about your personal safety.

Summary Table:

| Key Feature | Function | Benefit |

|---|---|---|

| Specialized Tread Pattern | Channels liquids away from the sole | Prevents hydroplaning on wet floors |

| Deep Grooves | Increases surface area and edges | Provides superior grip and stability |

| Advanced Rubber Compound | Conforms to floor irregularities | Ensures reliable traction on slick surfaces |

Ensure your team's safety with professional-grade footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, from styles designed for kitchens and restaurants to durable options for construction and healthcare. We combine advanced materials and purpose-built designs to deliver reliable traction and long-lasting performance. Contact us today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health