At their core, military boots are engineered with a system of protective elements designed for durability, safety, and performance in harsh conditions. Key features include reinforced toe caps, puncture-resistant outsoles, durable upper materials like full-grain leather, and specialized designs for traction and ankle support.

True protection in a military boot isn't about a single feature, but about a comprehensive system. It combines structural reinforcement against physical threats with advanced materials that shield you from environmental hazards and instability.

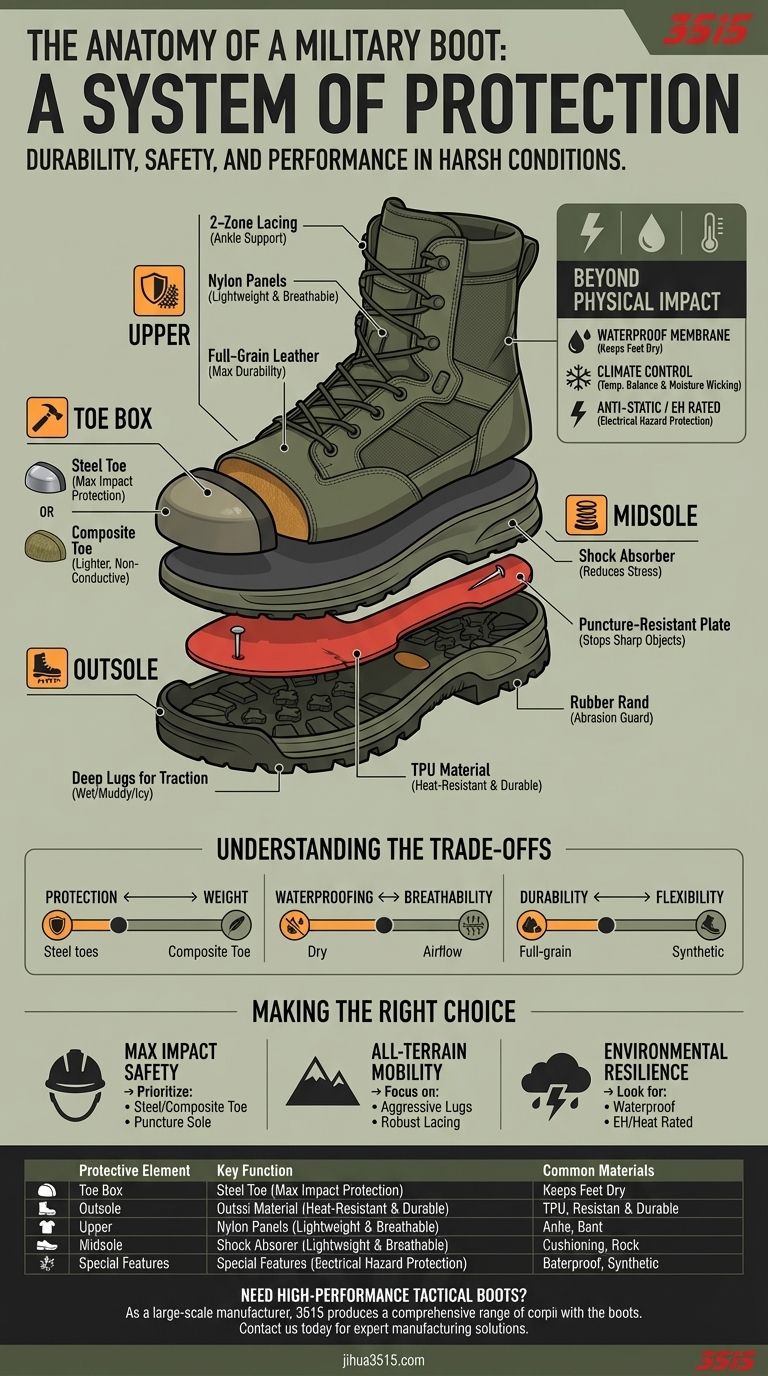

The Anatomy of Protection: A Component-by-Component Breakdown

To understand how a boot protects you, we must look at how its individual parts work together. The construction is divided into three primary zones: the upper, the midsole, and the outsole.

The Upper: Your First Line of Defense

The upper section wraps your foot and ankle, providing the first layer of defense against abrasions, weather, and impacts.

Materials like full-grain leather offer maximum durability and water resistance, while panels of nylon fabric reduce weight and increase breathability. A 2-zone lacing system is crucial for securing the ankle, preventing twists and sprains on uneven ground.

The Toe Box: Shielding Against Impact

The toe area is frequently reinforced to protect against crushing and impact injuries. This is where you find specific safety features.

Steel toe caps offer the highest level of protection against heavy falling objects. Composite toes, made from materials like Kevlar or carbon fiber, provide excellent protection while being lighter than steel and not conducting electricity.

The Midsole: The Unseen Shock Absorber

Located between your foot and the outsole, the midsole's primary protective role is cushioning. It absorbs shock from walking and running on hard surfaces, reducing stress on your feet and joints.

The Outsole: Your Connection to the Ground

The outsole is the workhorse of the boot, facing direct contact with the terrain. Its design is critical for both safety and durability.

A key feature is a puncture-resistant sole, which includes a protective plate to stop nails, glass, and sharp rocks from penetrating the boot. The material itself, often a lightweight TPU (Thermoplastic Polyurethane), is designed to be heat-resistant and durable.

Excellent traction is achieved through deep grooves (lugs) and specialized rubber compounds that grip wet, muddy, or icy surfaces to prevent slips and falls. Many designs also feature a rubber rand—a protective strip wrapped around the boot's lower edge—to guard against cuts and abrasions.

Beyond Physical Impact: Environmental and Hazard Protection

Modern military and tactical boots offer protection that goes beyond fending off rocks and debris. They are designed to mitigate environmental and occupational hazards.

Guarding Against Environmental Elements

A waterproof layer or membrane is often integrated into the boot's construction to keep feet dry in wet conditions. High-end boots also incorporate Climate Control Systems that help balance temperature, wicking moisture away to keep feet comfortable in both hot and cold environments.

Mitigating Electrical Risks

For personnel working near potential electrical threats, specialized boots are available. Anti-static boots dissipate the buildup of static electricity from the body. Boots with an Electrical Hazard (EH) rating are constructed with non-conductive soles to protect the wearer from open circuits.

Understanding the Trade-offs

Selecting the right boot always involves balancing competing characteristics. Understanding these trade-offs is key to choosing the correct tool for the job.

Protection vs. Weight

The most protective features, like steel toes and thick puncture-proof soles, add significant weight. This can increase fatigue over long distances. Lighter composite materials offer a compromise but may not provide the same level of absolute impact resistance.

Waterproofing vs. Breathability

A fully waterproof membrane is excellent at keeping water out, but it can also trap sweat and heat inside. This can lead to discomfort and blisters in hot climates. A boot with a balance of water resistance and breathability is often more versatile.

Durability vs. Flexibility

The toughest materials, like thick full-grain leather, provide incredible durability and support but often require a lengthy break-in period. More flexible synthetic materials may be comfortable out of the box but may not withstand the same level of long-term abuse.

Making the Right Choice for Your Goal

Your specific needs should dictate which protective elements you prioritize.

- If your primary focus is maximum impact safety: Prioritize boots with certified steel or composite safety toes and a puncture-resistant sole.

- If your primary focus is all-terrain mobility: Focus on boots with an aggressive lug pattern for superior traction and a robust lacing system for ankle support.

- If your primary focus is environmental resilience: Look for boots with a reliable waterproof membrane and a rating for electrical hazard or heat resistance if your environment demands it.

Ultimately, choosing the right boot is about matching its protective systems to the specific challenges you expect to face.

Summary Table:

| Protective Element | Key Function | Common Materials/Features |

|---|---|---|

| Toe Box | Protects against impact/crushing | Steel toe, Composite toe (Kevlar/carbon fiber) |

| Outsole | Prevents punctures & provides traction | Puncture-resistant plate, TPU material, Deep lugs |

| Upper | Shields from abrasion & weather | Full-grain leather, Nylon panels, 2-zone lacing |

| Midsole | Absorbs shock for joint comfort | Cushioning foam/compounds |

| Special Features | Guards against environmental hazards | Waterproof membrane, Electrical Hazard (EH) rating |

Need high-performance tactical boots built for your specific challenges?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and tactical boots, ensuring your team has the right protection for any environment.

Contact us today to discuss your requirements and benefit from our expert manufacturing solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the main threats to suede military boots? Protect Your Gear from Premature Failure

- Why is it important to wear proper boots when riding a motorcycle? Essential Protection for Every Rider

- Can regular soap be used to clean military boots? Choose the Right Soap to Protect Your Investment

- How does the Goodyear Welt construction improve the technical value of military boots? The Ultimate Durability Guide

- What materials are commonly used in military boots? A Guide to Durable, Protective Footwear

- What was the historical significance of the Clarks' Desert Boot? From Military Staple to Style Icon

- What are the key factors to consider when choosing military boots? Find the Perfect Fit for Your Mission

- How do Air Force boots differ from Army boots? Decoding Service Regulations for the Right Fit