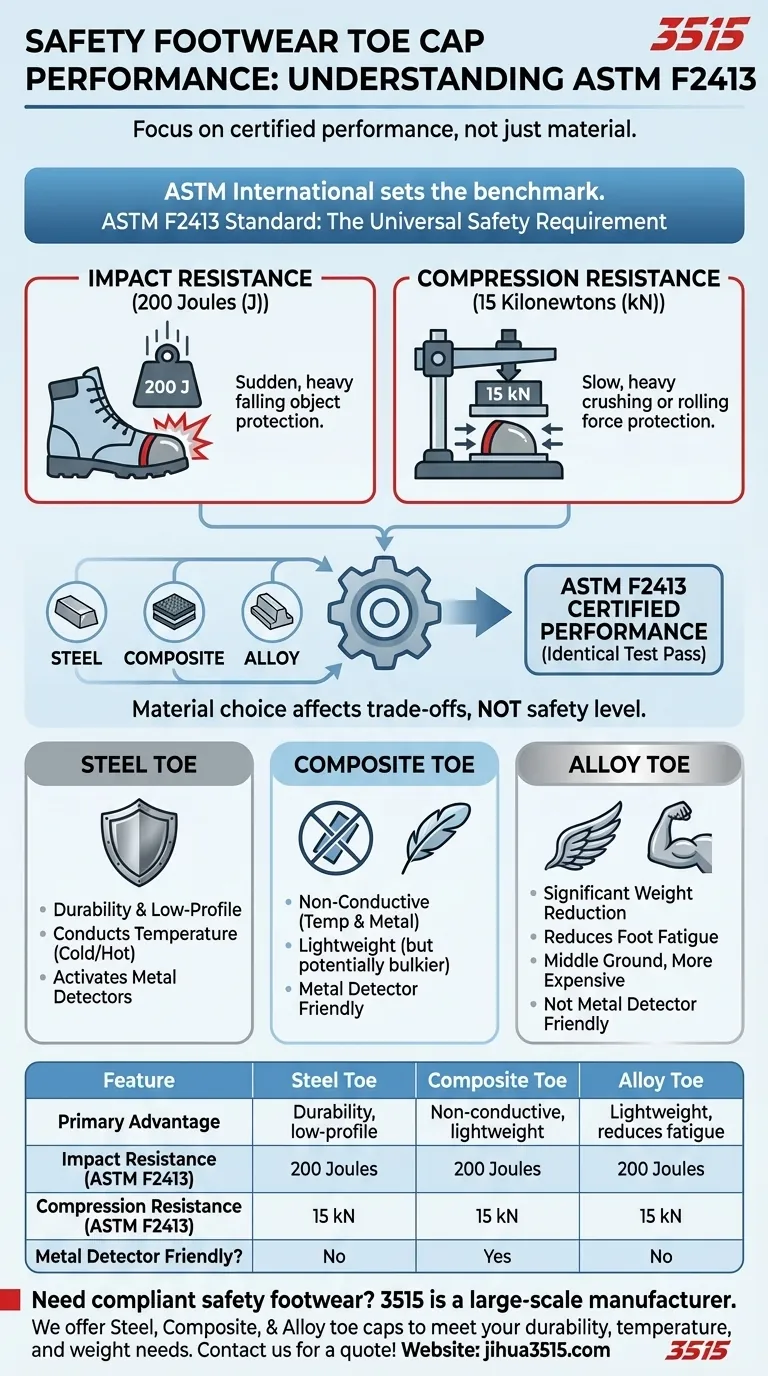

The primary organization that sets the performance standards for safety footwear toe caps in the United States is ASTM International. This body, formerly known as the American Society for Testing and Materials, establishes the benchmark for safety with its ASTM F2413 standard, which defines the required resistance to both impact and compression forces.

The critical takeaway is that while ASTM International sets the standard, the specific material of the toe cap—be it steel, composite, or alloy—is less important than its certified performance rating. All materials must pass the exact same minimum safety tests to be compliant.

Deconstructing the ASTM F2413 Standard

To understand safety footwear, you must first understand the core components of the standard it's measured against. ASTM F2413 is not a single benchmark but a combination of tests for different hazards.

Impact Resistance

This test measures the toe cap's ability to protect the foot from a sudden, heavy falling object. A weight is dropped from a specified height to generate a specific impact energy.

For the highest-rated protective toe cap, it must withstand an impact energy of 200 Joules (J).

Compression Resistance

This test measures the toe cap's ability to protect the foot from a slow, heavy crushing or rolling force. A static load is applied until it reaches a specified force.

The standard requires the toe cap to withstand a compressive force of 15 Kilonewtons (kN), which is equivalent to thousands of pounds of static pressure.

Material vs. Performance: A Critical Distinction

A common point of confusion is whether steel, composite, or alloy toe caps offer "better" protection. The ASTM standard clarifies this by focusing purely on performance, not composition.

The Role of Different Materials

Manufacturers can use various materials to achieve the safety standard, including steel, aluminum alloys, and non-metallic composites (like plastic or carbon fiber).

The Performance Mandate

Regardless of whether a toe cap is made of steel or plastic, it must pass the same impact and compression tests to earn the ASTM F2413 certification. The material choice does not change the minimum safety requirement; it only changes other properties of the footwear.

Understanding the Trade-offs

The choice between steel, composite, or alloy toes is not about which is "safer" from a standards perspective, but about which is better suited for your specific work environment and needs.

Steel Toes

Steel is the traditional material for safety toes. It is exceptionally strong, allowing for a slightly thinner and less bulky toe cap profile compared to some composites. However, steel conducts temperature, making it feel colder in winter and hotter in summer, and it will activate metal detectors.

Composite Toes

Composite toes are made from non-metallic materials like plastic, carbon fiber, or Kevlar. Their primary advantage is that they do not conduct heat or cold and do not set off metal detectors. They are also typically lighter than steel, but may be slightly thicker to provide the same level of protection.

Alloy Toes

Alloy toes, often made from materials like aluminum, offer a middle ground. They provide the necessary impact and compression resistance while being significantly lighter than steel. They are a good choice for reducing foot fatigue but are often more expensive.

Making the Right Choice for Your Goal

Look for the ASTM F2413 label inside the footwear, then select a material based on your daily tasks.

- If your primary focus is durability and a low-profile cap: Steel toes remain the classic, cost-effective choice that meets the highest safety standards.

- If you work in extreme temperatures or pass through metal detectors: Composite toes are the superior option for thermal insulation and hassle-free screening.

- If your primary goal is to minimize foot fatigue and weight: Alloy toes provide top-tier protection at a fraction of the weight of steel.

Ultimately, choosing the right safety footwear begins with verifying the ASTM rating, then selecting the material that best serves the unique demands of your workday.

Summary Table:

| Feature | Steel Toe | Composite Toe | Alloy Toe |

|---|---|---|---|

| Primary Advantage | Durability, low-profile | Non-conductive, lightweight | Lightweight, reduces fatigue |

| Impact Resistance (ASTM F2413) | 200 Joules | 200 Joules | 200 Joules |

| Compression Resistance (ASTM F2413) | 15 kN | 15 kN | 15 kN |

| Metal Detector Friendly? | No | Yes | No |

Need compliant safety footwear for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-certified safety footwear for distributors, brand owners, and bulk clients. We offer steel, composite, and alloy toe caps to meet your specific needs for durability, temperature resistance, and weight reduction.

Contact us today to discuss your safety footwear requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries