In the United States, the organization that develops the safety standards for protective footwear is ASTM International, formerly known as the American Society for Testing and Materials. However, it is the Occupational Safety and Health Administration (OSHA) that legally requires employers to ensure their workers wear footwear that meets these ASTM standards in hazardous environments.

While ASTM International sets the technical benchmarks for what makes footwear "safe," it is OSHA that enforces the use of this compliant footwear in the workplace, creating a critical partnership between the two organizations.

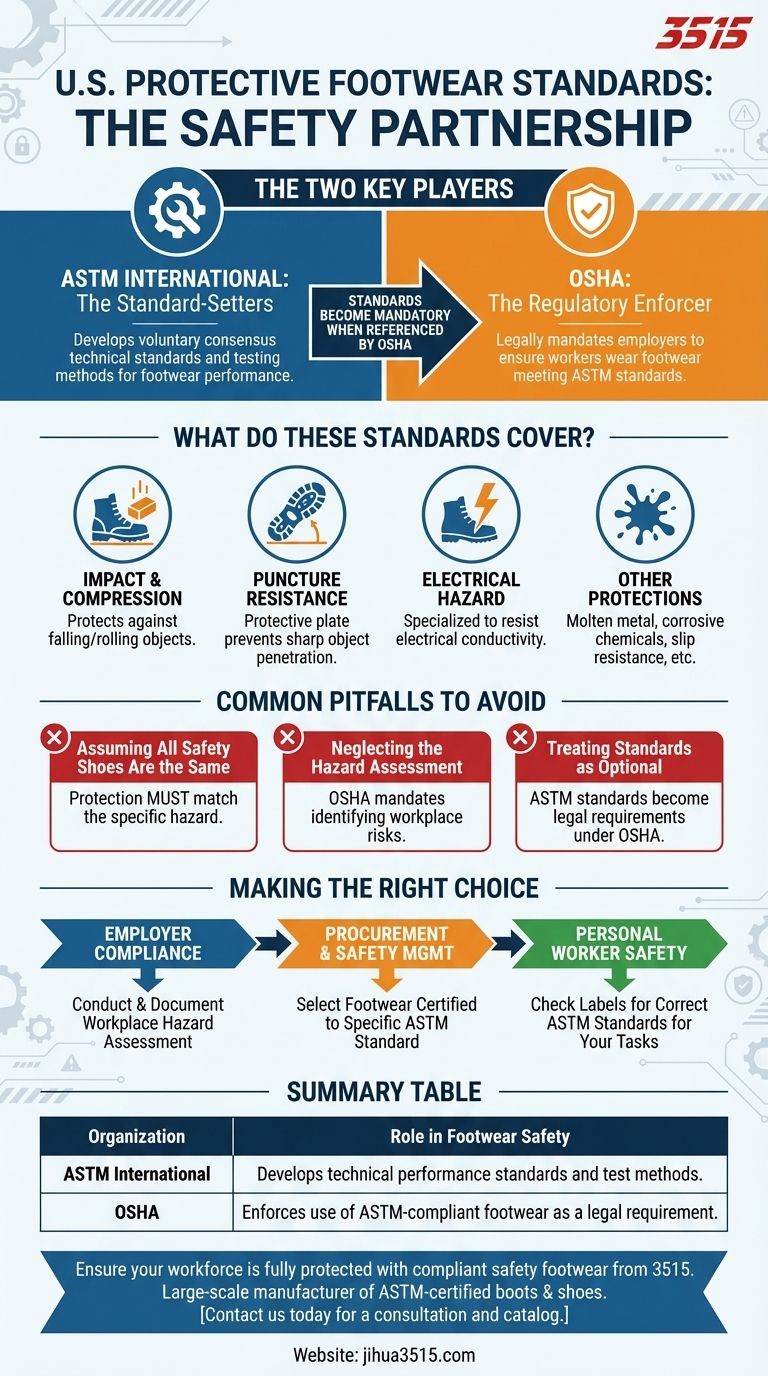

The Two Key Players: ASTM and OSHA

Understanding protective footwear requirements means understanding the distinct roles these two organizations play. They are not interchangeable; one sets the technical standard, and the other mandates its use.

ASTM International: The Standard-Setters

ASTM International is a global organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, and services.

For footwear, ASTM committees define specific performance criteria. They establish the testing methods to certify that a boot or shoe can withstand certain impacts, resist punctures, or protect against electrical shocks.

OSHA: The Regulatory Enforcer

The Occupational Safety and Health Administration (OSHA) is a U.S. government agency tasked with ensuring safe and healthful working conditions.

OSHA does not write its own footwear performance standards. Instead, its regulations, such as 29 CFR 1910.136(a), legally require employers to provide protective footwear that meets the appropriate ASTM standards whenever workplace hazards demand it.

What Do These Standards Actually Cover?

OSHA requires employers to perform a hazard assessment to determine the specific dangers present. Based on that assessment, they must select footwear certified by ASTM to protect against those identified risks.

Impact and Compression Resistance

This is the most common feature, designed to protect the foot from injuries caused by falling or rolling objects, such as heavy equipment or materials.

Puncture Resistance

Standards for puncture resistance involve a protective plate placed in the sole to prevent sharp objects like nails or metal shards from piercing the bottom of the foot.

Electrical Hazard Protection

Specialized footwear is designed to protect workers from open electrical circuits. These standards specify the shoe's ability to resist electrical conductivity and reduce the risk of electric shock.

Other Specialized Protections

ASTM standards also cover a variety of other risks, including protection from splashes of molten metal, corrosive or poisonous materials, and slipping on hot or slick surfaces.

Common Pitfalls to Avoid

The responsibility for safety footwear does not end with simply buying a pair of "steel-toed boots." The system is more nuanced, and misunderstanding it can lead to non-compliance and worker injury.

Assuming All Safety Shoes Are the Same

Not all protective footwear is created equal. A boot rated for impact resistance offers no protection from an electrical hazard unless it is also certified for that specific purpose. The protection must match the hazard.

Neglecting the Hazard Assessment

OSHA mandates that the employer must assess the workplace to determine if foot hazards are present. Failing to perform this assessment is a common point of failure and a direct violation of regulatory requirements.

Treating Standards as Optional

While ASTM standards are technically "voluntary" for manufacturers to adopt, they become mandatory legal requirements the moment OSHA references them in its regulations for workplace safety.

Making the Right Choice for Your Goal

Selecting the correct footwear is a critical safety decision based on defined roles and responsibilities.

- If your primary focus is on employer compliance: Your first duty is to conduct and document a thorough workplace hazard assessment to identify every potential foot injury risk.

- If your primary focus is on procurement and safety management: You must select and provide footwear that is explicitly certified to the specific ASTM standard that corresponds to the hazards identified in your assessment.

- If your primary focus is on personal worker safety: Always check the labels and markings inside your footwear to confirm it meets the necessary ASTM standards for the tasks you are performing.

Ultimately, understanding the distinct roles of ASTM's technical expertise and OSHA's regulatory authority is the foundation of any effective foot protection program.

Summary Table:

| Organization | Role in Footwear Safety |

|---|---|

| ASTM International | Develops the technical performance standards and test methods for protective footwear. |

| OSHA (Occupational Safety & Health Administration) | Enforces the use of ASTM-compliant footwear as a legal requirement in hazardous workplaces. |

Ensure your workforce is fully protected with compliant safety footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, including styles rated for impact, compression, puncture, and electrical hazards.

Let us help you meet OSHA requirements and protect your team. Contact us today for a consultation and to explore our catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What is the importance of professional rubber safety boots for skin protection? Ensure High-Level Agricultural Safety

- How can you tell if work shoes have enough arch support? Identify the Signs for Better Comfort

- What is the requirement for front foot protection under EN ISO 20345? The 200 Joule Safety Standard Explained

- What does OSHA standard 29 CFR 1910.136(a) require regarding protective footwear? Ensure Compliance & Worker Safety

- What role does material play in work shoes? Choose the Right System for Safety & Comfort

- How does a vibration motor function in smart obstacle-avoidance shoes? Explore Haptic Feedback for Blind Navigation

- What are the key differences between S4/S5 and other classes? A Guide to Waterproof vs. Breathable Safety Boots

- What does the impact rating in safety toe boots mean? Choose the Right Protection for Your Job