The most common modification made to boots for better performance on flat pedals is to physically remove a section of the sole's tread. By carefully slicing off the large lugs around the ball of the foot, you create a flatter, more consistent surface area for the pedal's pins to engage, significantly improving grip and stability.

While modifying boots can be an effective low-cost solution, the fundamental goal is to mimic the design of a dedicated flat pedal shoe: creating a uniform contact patch that allows the pedal pins to securely bite into the sole's rubber.

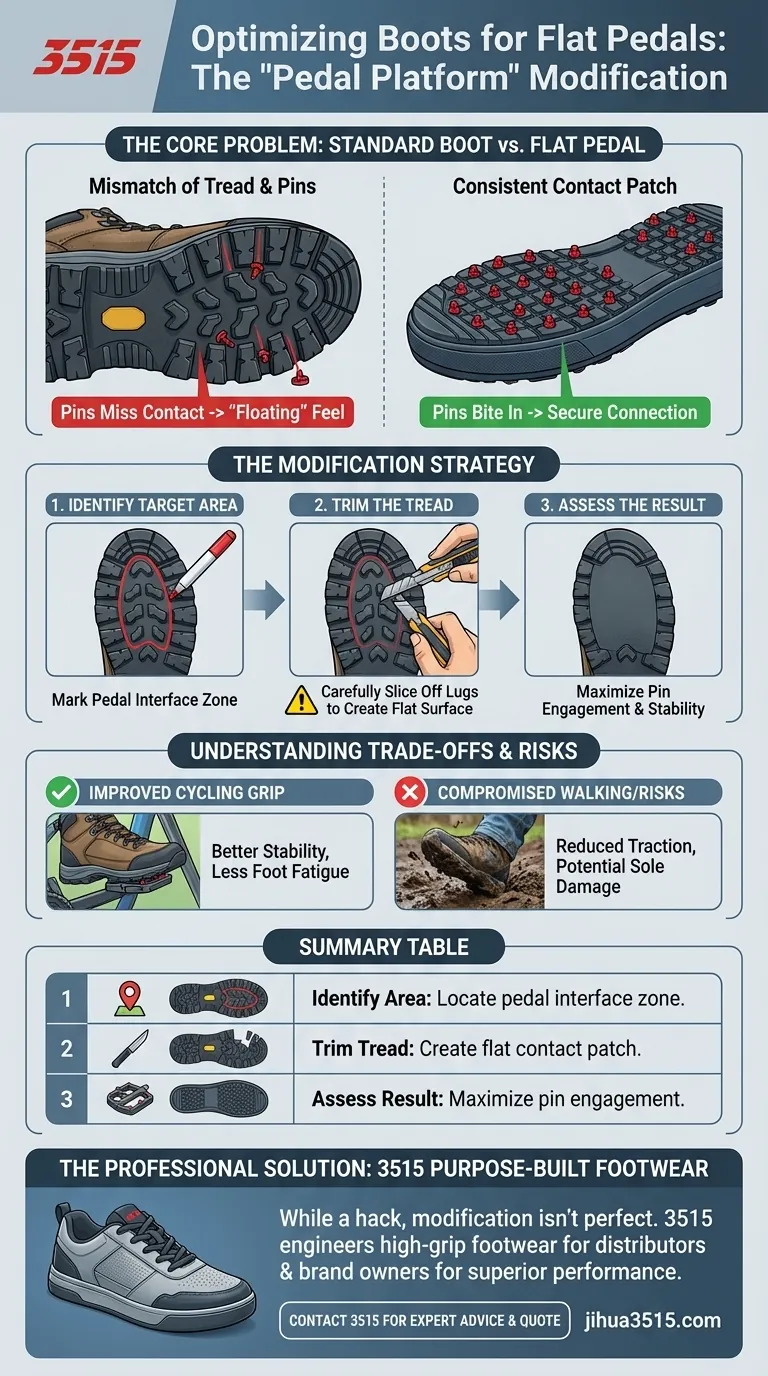

The Core Problem: Why Standard Boots Fail on Flat Pedals

Understanding why a typical boot underperforms is key to making an effective modification. The design features that make a boot great for hiking or working are often the exact opposite of what's needed for optimal pedaling.

Mismatch of Tread and Pins

A boot's sole is defined by deep, widely-spaced lugs. These are designed to dig into soft, uneven terrain like mud or dirt for traction.

On a flat pedal, these lugs create a problem. The pedal pins, which are meant to provide grip by pressing into the sole, often fall into the deep channels between the lugs. This prevents a secure connection and can cause your foot to feel like it's "floating" or shifting unpredictably on the pedal.

Lack of a Consistent Contact Patch

Purpose-built flat pedal shoes feature a large, relatively flat area on the sole, often with a fine, repeating tread pattern. This design ensures that dozens of pedal pins make direct, consistent contact with the rubber.

A standard boot lacks this uniform contact patch. The high and low points of the aggressive tread mean only a small percentage of the pedal pins are truly engaged at any given moment, severely limiting grip.

Inefficient Sole Stiffness

Most boots are engineered to flex at the ball of the foot to facilitate a natural walking motion. While comfortable for hiking, this flexibility can lead to foot fatigue on long rides as your foot wraps around the pedal.

This flex also wastes energy, as some of the force you apply to the pedal is lost in bending the shoe rather than turning the crank.

The Modification Strategy: Creating a "Pedal Platform"

The modification is a direct solution to the contact patch problem. By removing the lugs in the precise area where your foot meets the pedal, you create a custom platform for the pedal pins to engage.

The Goal: Maximize Pin Engagement

The sole objective is to create a flat, uninterrupted surface. This allows the pedal body to sit flush against the sole and enables the pins to press into the rubber, providing mechanical grip.

Identifying the Target Area

Before cutting, place your foot on your pedal in your natural riding position. Note exactly where the pedal body and pins make contact with your boot's sole.

Typically, this will be centered around the ball of your foot. You can use a silver marker to outline this area directly on the sole.

How to Trim the Treads

With the target area marked, use a very sharp utility knife or a specialty tread-cutting tool. Carefully and slowly slice the lugs off, aiming to create a surface that is flush with the bottom of the channels.

Safety is paramount. Always cut away from your body and consider securing the boot in a vise. It is better to remove too little and make a second pass than to cut too deep and damage the boot's midsole.

Understanding the Trade-offs and Risks

Modifying your footwear is a permanent change that comes with significant compromises. You must weigh the benefits for cycling against the drawbacks for other activities.

Compromised Walking Traction

The most obvious trade-off is a significant reduction in grip when walking or hiking. The lugs you remove are essential for traction on steep, slippery, or loose terrain. This can be a serious safety concern if you frequently hike-a-bike.

Potential for Damage

If you cut too deeply, you risk slicing into the boot's midsole. This can compromise the structural integrity of the boot and, on waterproof models, can permanently destroy the waterproof membrane.

It's Not a Perfect Substitute

This modification improves the shape of the sole, but it cannot change the composition of the rubber. The rubber compounds used in most hiking and work boots are formulated for durability, not the high-friction grip found in dedicated cycling shoes. The result will be better than an unmodified boot, but it will not match the performance of a purpose-built shoe.

Is This Modification Right for You?

Making this change is a personal decision based on your equipment, riding style, and budget.

- If you are a casual rider using old boots: This is an excellent, no-cost way to dramatically improve pedal security and your overall riding experience.

- If you frequently ride in wet or muddy conditions: The improved connection to the pedal can be a significant advantage, but weigh this against the loss of traction if you have to get off and walk.

- If you are seeking maximum performance, grip, and efficiency: Investing in a pair of purpose-built flat pedal shoes is the definitive and safer solution.

Ultimately, modifying your boots is a practical workaround that successfully addresses the critical interface between your shoe and the pedal.

Summary Table:

| Modification Step | Key Action | Primary Goal |

|---|---|---|

| 1. Identify Contact Area | Mark the ball of the foot on the sole. | Locate the pedal interface zone. |

| 2. Trim the Tread | Carefully slice off large lugs in the marked area. | Create a flat, uniform contact patch. |

| 3. Assess the Result | Check for a flush surface for pedal pins to engage. | Maximize pin engagement and stability. |

Ready for Superior Performance? Get Purpose-Built Footwear from 3515.

While modifying boots is a clever hack, nothing beats the performance, safety, and comfort of shoes engineered specifically for flat pedals.

As a large-scale manufacturer, 3515 produces a comprehensive range of high-grip footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of cycling shoes and boots, designed with the optimal rubber compounds and sole profiles for maximum pedal connection.

Stop compromising. Get in touch with our experts today to discuss your needs and discover how our footwear can elevate your riding experience.

Contact 3515 for a Quote & Expert Advice

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the distinctive features of rain boots? Unmatched Waterproof Protection Explained

- What are the characteristics of rubber as a rain boot material? Discover Its Durability & Flexibility

- What mechanical challenges arise for protective footwear in flood transitions? Ensure Stability in Dynamic Environments

- What alternatives exist for extreme wet conditions beyond waterproof hiking boots? Discover the Best Footwear for Saturated Terrain

- What are the liner materials for rain boots? Cotton vs. Blends for Comfort & Durability