To immediately make your slippers less slippery, you must physically alter the sole's surface to increase friction. The most effective methods are scuffing the bottoms with sandpaper to create a rougher texture, applying a specialized non-slip spray to add a tactile coating, or attaching adhesive grip pads for the most significant improvement in traction.

The core issue is that most slippers prioritize comfort over safety, resulting in smooth soles with minimal grip. The solution is not to find a magic product, but to fundamentally change the slipper's contact point with the floor from a smooth surface to a textured one.

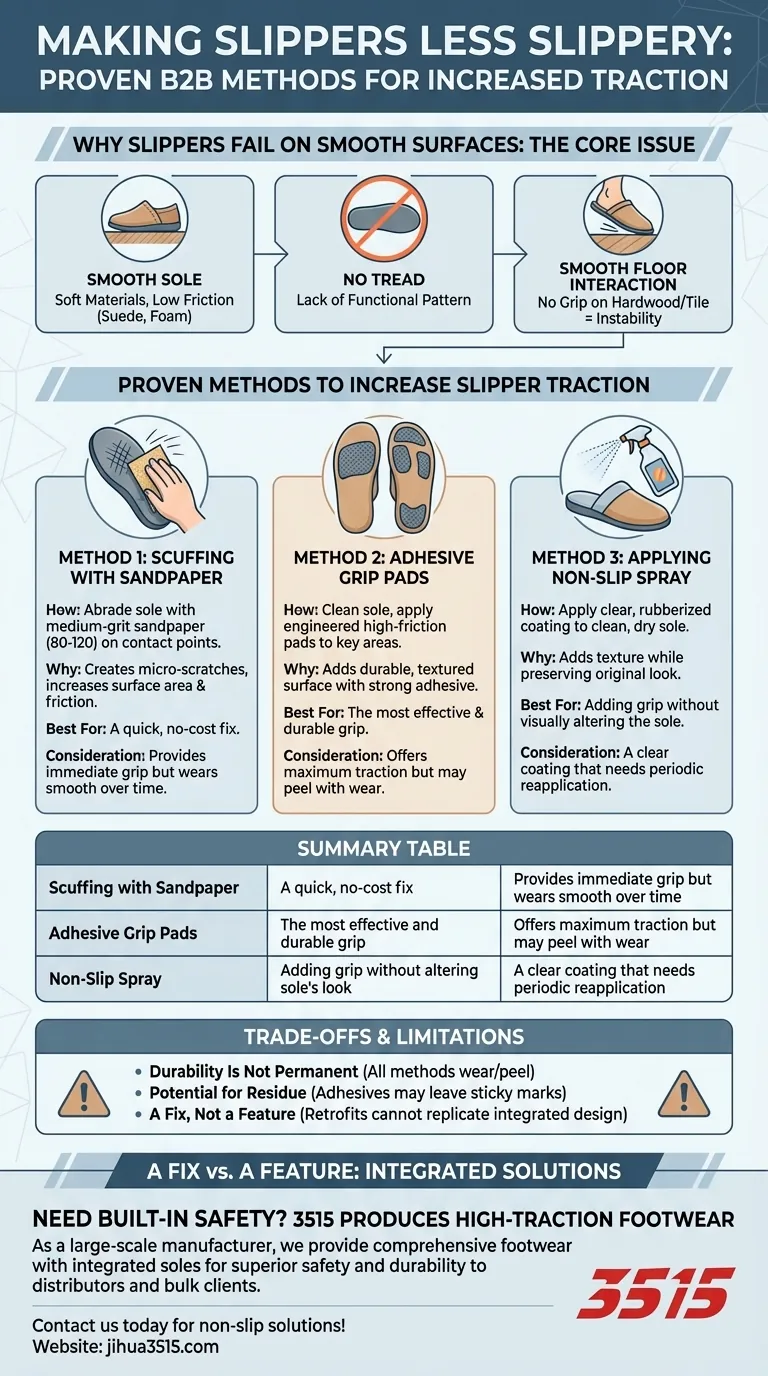

Why Slippers Fail on Smooth Surfaces

Before modifying your slippers, it’s crucial to understand why they are slippery in the first place. The problem is a simple matter of physics centered on friction, which is often an afterthought in slipper design.

The Smooth Sole Problem

Most slippers use materials like soft suede, felt, or smooth, molded foam for their soles. While comfortable, these materials have a very low coefficient of friction against common indoor surfaces.

The Lack of Tread

Unlike outdoor shoes, slippers rarely have a deep, functional tread pattern. A proper tread is designed to bite into surfaces and channel away tiny particles of dust or moisture that can act like microscopic ball bearings underfoot.

The Floor-Slipper Interaction

The combination of a smooth, treadless slipper and a polished floor—like hardwood, tile, or laminate—creates a perfect scenario for slips. There is nothing for the two surfaces to "grip" onto, resulting in instability.

Proven Methods to Increase Slipper Traction

Each method works by introducing texture and roughness to the sole, thereby increasing its ability to grip the floor.

Method 1: Scuffing with Sandpaper

This is the fastest, lowest-cost method for creating immediate grip. By abrading the sole, you create thousands of micro-scratches that increase the surface area and create friction.

Use a medium-grit sandpaper (around 80-120 grit) and firmly rub the areas of the sole that make the most contact with the ground, primarily the ball and heel. Continue until any shiny, smooth finish is visibly dulled.

Method 2: Applying Non-Slip Spray

Specialty grip sprays apply a clear, slightly rubberized coating to the bottom of footwear. This is an excellent option for preserving the original look of a sole while adding a layer of texture.

Ensure the slipper's sole is perfectly clean and dry before application. Follow the product's instructions, typically involving an even coat and adequate drying time. Be aware that this coating may need to be reapplied over time as it wears away.

Method 3: Attaching Adhesive Grip Pads

This is often the most durable and effective solution. These pads are specifically engineered with a high-friction, textured surface and a strong adhesive backing.

For best results, clean the slipper sole with rubbing alcohol to remove any oils or residue. This ensures the strongest possible bond. Place the pads on the key contact points (ball and heel) for maximum effectiveness.

Understanding the Trade-offs and Limitations

While these methods are effective, they are retrofits to a product not originally designed for high traction. It's important to be aware of the potential downsides.

Durability Is Not Permanent

Scuffing will smooth out again with wear. Sprays will eventually wear off. Even the best adhesive pads can begin to peel at the edges over time, especially if the slippers get wet.

Potential for Residue

An overly aggressive adhesive on a grip pad could leave a sticky residue on your floors if it begins to peel off. While uncommon, it is a possibility to be aware of.

A Fix, Not a Feature

These modifications improve safety, but they cannot replicate the integrated design of a slipper built from the ground up with a high-traction, all-weather rubber sole. For maximum safety, consider the sole material during your next purchase.

Making the Right Choice for Your Goal

Your best approach depends on the type of slipper you have and the level of security you need.

- If your primary focus is a quick, no-cost fix: Scuffing the soles with sandpaper is the most immediate and accessible solution.

- If your primary focus is the most effective and durable grip: Applying high-quality, self-adhesive grip pads offers the most significant improvement.

- If your primary focus is to add grip without visibly altering the sole: A clear, non-slip spray is the ideal choice for maintaining the original look.

By deliberately modifying the contact surface of your soles, you can transform slippery footwear into a secure and stable foundation for moving safely around your home.

Summary Table:

| Method | Best For | Key Consideration |

|---|---|---|

| Scuffing with Sandpaper | A quick, no-cost fix | Provides immediate grip but wears smooth over time |

| Adhesive Grip Pads | The most effective and durable grip | Offers maximum traction but may peel with wear |

| Non-Slip Spray | Adding grip without altering the sole's look | A clear coating that needs periodic reapplication |

Need non-slip footwear designed for safety from the ground up?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including slippers with integrated high-traction soles for superior safety and durability. Stop relying on temporary fixes—let us help you provide or source footwear built for stability.

Contact us today to discuss your non-slip footwear needs!

Visual Guide

Related Products

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Why is proper fit important in work boots? Ensure Safety, Comfort & Long-Term Health

- What are the potential consequences of wearing improperly designed work boots? Avoid Injury & Boost Safety

- Why is maintenance important for work boots? Protect Your Investment and Safety

- How does ASTM differ from ANSI? Navigating the U.S. Standards System for Compliance

- What is ASTM International and what does it do? A Guide to Global Standards