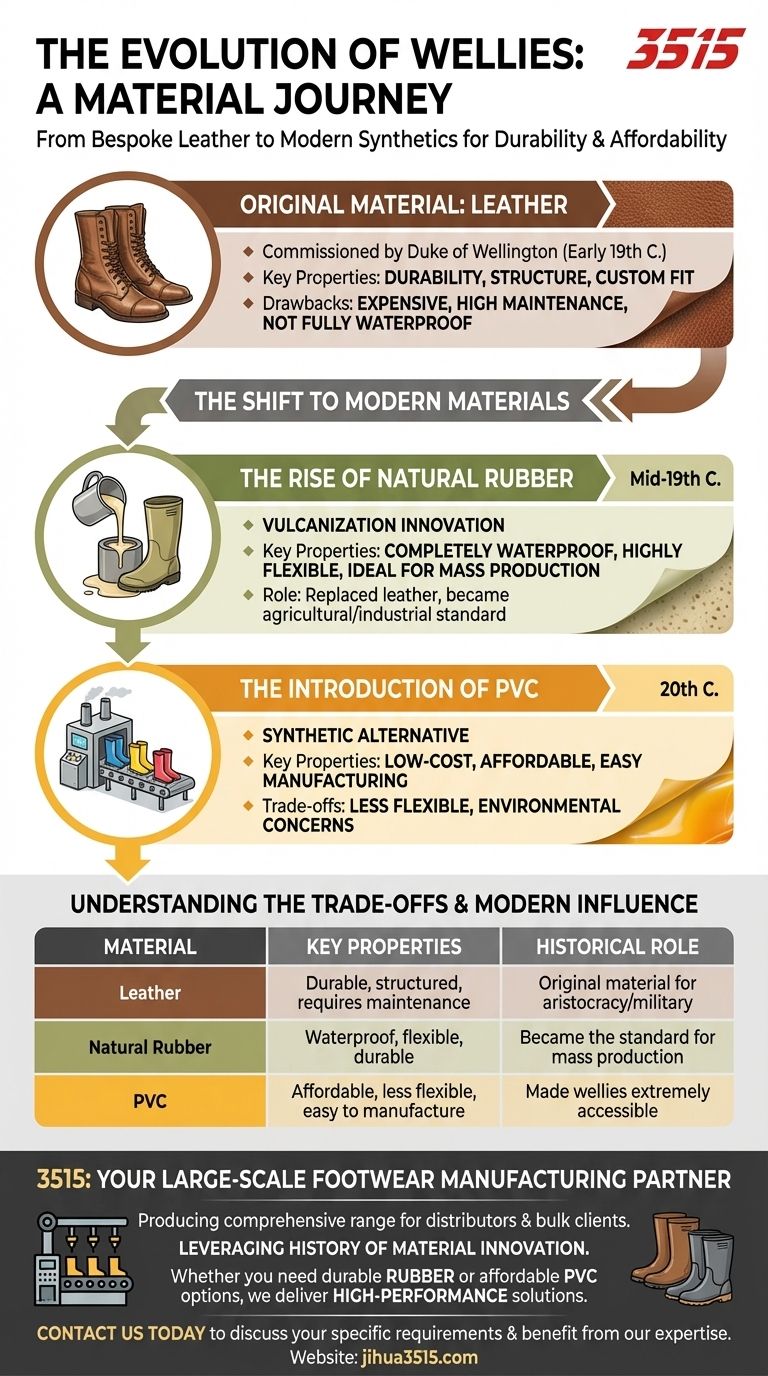

Traditionally, wellington boots were made from leather. This original design, intended for aristocracy and military officers, eventually gave way to more practical and affordable materials. The most significant shift was to rubber and later to PVC, which made the boots accessible for widespread agricultural and general use.

The evolution of the welly is a story of material innovation driven by a single goal: creating a durable, affordable, and completely waterproof boot. The journey from bespoke leather to mass-produced synthetics reflects a fundamental trade-off between traditional craftsmanship and modern industrial efficiency.

The Original Material: Leather

The Era of the Leather Wellington

The very first boots commissioned by the Duke of Wellington in the early 19th century were crafted from treated leather. They were designed as a hard-wearing, comfortable alternative to the standard military-issue Hessian boots of the time.

Key Properties of Leather

Leather was chosen for its exceptional durability and structure. It could be tailored for a close fit, offering far more support and comfort than the looser boots it replaced.

The Inevitable Decline

Despite its durability, leather had two major drawbacks for a utility boot: it was expensive to produce and required significant maintenance to remain water-resistant. This limited its use to the wealthy and the military.

The Shift to Modern Materials

The Rise of Natural Rubber

The invention of vulcanized rubber in the mid-19th century was the true turning point for the welly. This process created a material that was both completely waterproof and highly flexible, making it ideal for mass production.

Natural rubber quickly replaced leather as the standard for wellington boots, transforming them from a military boot into an essential piece of footwear for agricultural and industrial workers.

The Introduction of PVC

In the 20th century, PVC (Polyvinyl Chloride) emerged as a low-cost synthetic alternative to natural rubber. Its affordability and ease of manufacturing led to another massive shift in the market.

This change made wellies more accessible than ever before, but it also introduced new considerations regarding performance and environmental impact.

Understanding the Trade-offs

Leather: Durability vs. Practicality

The original leather boot offered excellent durability and a custom fit but was never fully waterproof without constant treatment. Its high cost and maintenance made it impractical for the average person.

PVC: Affordability vs. Environment

PVC made wellies extremely affordable but came with compromises. It is often less flexible than rubber, especially in cold weather, and its production involves chemical treatments that are not environmentally friendly.

Natural Rubber: The Modern Standard

Natural rubber established the benchmark for a high-quality welly. It provides an excellent balance of waterproofing, flexibility, and durability, though it remains a more premium and costly material than PVC.

How Traditional Materials Influence Today's Boots

Understanding this history helps you recognize the legacy of these materials in modern footwear.

- If your primary focus is heritage and classic style: Look for boots made from treated leather or high-end synthetic leathers, which honor the original design.

- If your primary focus is affordability for basic tasks: Many entry-level wellies are still made from PVC, reflecting its historical role as the most economical option.

- If your primary focus is all-around performance and comfort: Natural rubber remains the gold standard, offering the durability and flexibility that first perfected the modern welly.

Recognizing the material lineage of a boot allows you to choose the right tool for the job based on decades of innovation.

Summary Table:

| Material | Key Properties | Historical Role |

|---|---|---|

| Leather | Durable, structured, requires maintenance | Original material for aristocracy/military |

| Natural Rubber | Waterproof, flexible, durable | Became the standard for mass production |

| PVC | Affordable, less flexible, easy to manufacture | Made wellies extremely accessible |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including high-performance wellington boots that leverage this rich history of material innovation.

Whether you need durable rubber boots for industrial use or affordable PVC options for general markets, we can deliver.

Contact us today to discuss your specific requirements and benefit from our expertise in manufacturing the right boot for your customers.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the main benefits of PVC boots? Unmatched Waterproof & Chemical Protection

- Why are tread patterns important in Wellington boots? Master Traction and Safety

- What are the two main materials used to make wellington boots? Rubber vs. PVC Explained

- Why is it important to clean rubber boots? Protect Your Investment and Extend Their Lifespan

- What are the advantages of rubber boots for deer hunting in terms of scent control? Master Stealth with Scent-Proof Footwear

- What are waterproof moc toe boots used for? Versatile Footwear for Work & Wet Weather

- Can wellies be washed in a washing machine? Avoid Costly Damage to Boots & Machine

- What are the primary benefits of wearing wellington boots for outdoor activities? Stay Dry and Protected in Any Weather