To ensure winter boot durability, look for robust core materials like full-grain leather, high-density rubber, and rugged synthetics like ballistic nylon. These materials are chosen specifically for their ability to withstand the demanding cycle of moisture, freezing temperatures, and physical abrasion common in winter conditions, which is the foundation of a long-lasting boot.

The key to durability is not a single "best" material, but rather how high-quality materials are strategically combined in the boot's construction. A truly durable boot excels in its upper, outsole, and the method used to join them together.

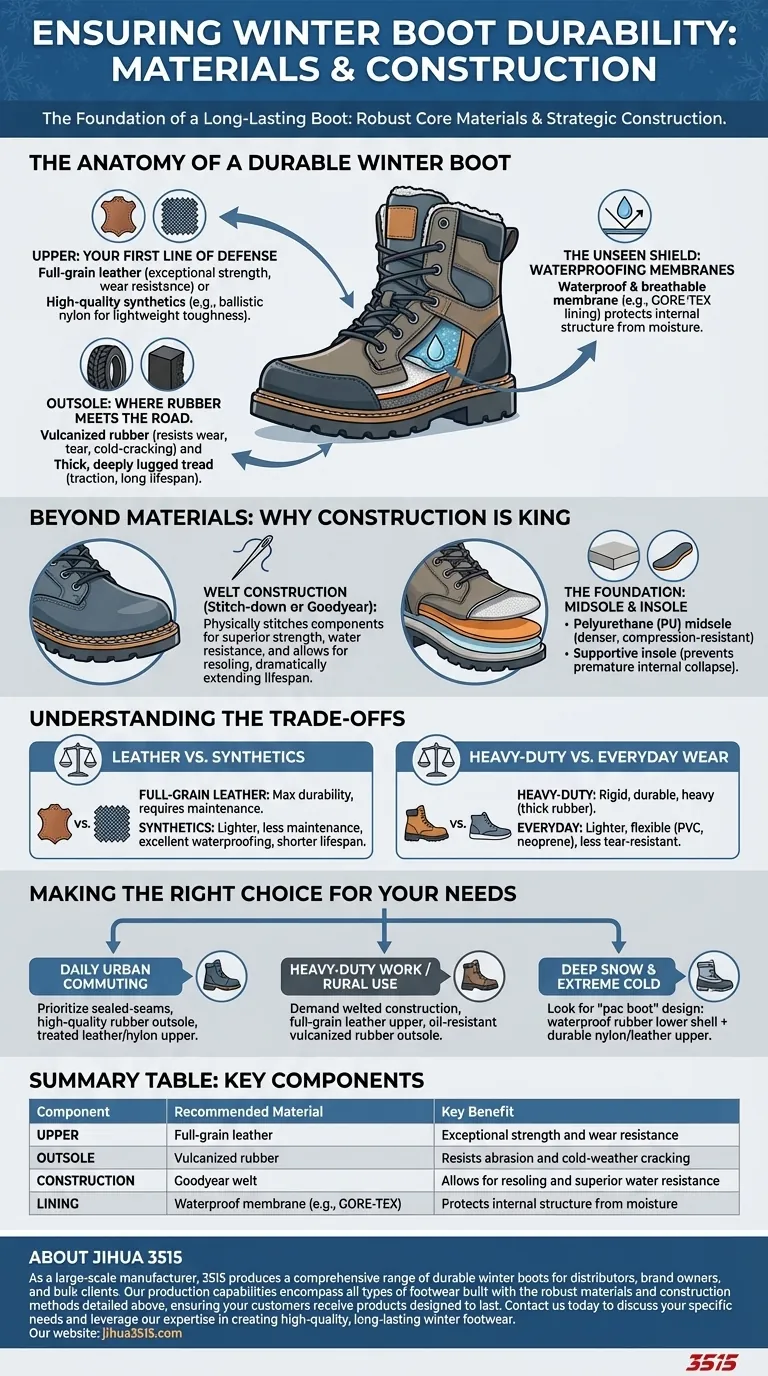

The Anatomy of a Durable Winter Boot

A boot's lifespan is determined by the quality of its individual parts. Each component serves a specific purpose, and the choice of material is critical to its function.

The Upper: Your First Line of Defense

The upper is the part of the boot that covers your foot. It faces the most direct exposure to snow, slush, and physical impacts.

Full-grain leather is the gold standard for its exceptional strength and resistance to wear. It is the most durable form of leather and can last for decades with proper care.

High-quality synthetics, such as ballistic or Cordura nylon, offer a lightweight yet tough alternative. These materials provide excellent resistance to tearing and abrasion.

The Outsole: Where Rubber Meets the Road

The outsole is the layer that makes direct contact with the ground. Its durability is non-negotiable for traction and longevity.

Vulcanized rubber is the premier material for outsoles. The vulcanization process reinforces the rubber, making it incredibly resistant to wear, tear, and cold-weather cracking.

Look for a thick, deeply lugged tread. This not only provides better grip on ice and snow but also means there is more material to wear down over time, extending the boot's usable life.

The Unseen Shield: Waterproofing Membranes

Durability isn't just about resisting scuffs; it's also about withstanding moisture that can break down materials over time.

A waterproof and breathable membrane, like a GORE-TEX lining, is laminated between the boot's outer material and its inner lining. This keeps water out while allowing sweat to escape, protecting the boot's internal structure from moisture damage.

Beyond Materials: Why Construction is King

The world's best materials will fail if they are poorly assembled. The construction method is a critical indicator of a boot's overall durability and repairability.

The Importance of Welt Construction

A welt is a strip of leather or rubber stitched around the bottom edge of the boot, connecting the upper to the outsole.

Stitch-down or Goodyear welt construction is a hallmark of high-end, durable footwear. This method physically stitches the components together, creating a far stronger and more water-resistant bond than simple gluing or cementing. It also allows the boot to be resoled, dramatically extending its lifespan.

The Foundation: Midsole and Insole

The midsole provides cushioning and support. Materials like polyurethane (PU) are superior to EVA foam, as PU is denser and far more resistant to compressing and breaking down over years of use.

A supportive, well-made insole contributes to the boot's structural integrity, ensuring comfort and preventing premature internal collapse.

Understanding the Trade-offs

Choosing the right material often involves balancing competing priorities. Absolute durability may come at the cost of weight or flexibility.

Leather vs. Synthetics

Full-grain leather offers maximum durability and can be maintained for years, but it requires periodic cleaning and conditioning.

Synthetics are often lighter, require less maintenance, and can provide excellent waterproofing out of the box, but may not have the same multi-decade lifespan as premium leather.

Heavy-Duty vs. Everyday Wear

A boot designed for heavy-duty work with an ultra-thick rubber sole and rigid construction will be incredibly durable but may feel too stiff and heavy for casual city walking.

Lighter materials like PVC or neoprene can be effective for less demanding conditions. They are not as tear-resistant as vulcanized rubber but offer more flexibility and a lower weight.

Making the Right Choice for Your Needs

Match the boot's materials and construction to your specific winter environment and activities.

- If your primary focus is daily urban commuting: Prioritize a sealed-seam construction with a high-quality rubber outsole for grip, combined with treated leather or nylon uppers for a balance of durability and style.

- If your primary focus is heavy-duty work or rural use: Demand a welted construction, a full-grain leather upper, and a thick, oil-resistant vulcanized rubber outsole.

- If your primary focus is deep snow and extreme cold: Look for a "pac boot" design that combines a completely waterproof rubber lower shell with a durable nylon or leather upper for maximum protection.

Ultimately, evaluating a boot's materials, construction, and intended purpose as a complete system is the most effective way to ensure you are investing in true winter durability.

Summary Table:

| Component | Recommended Material | Key Benefit |

|---|---|---|

| Upper | Full-grain leather | Exceptional strength and wear resistance |

| Outsole | Vulcanized rubber | Resists abrasion and cold-weather cracking |

| Construction | Goodyear welt | Allows for resoling and superior water resistance |

| Lining | Waterproof membrane (e.g., GORE-TEX) | Protects internal structure from moisture |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable winter boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of footwear built with the robust materials and construction methods detailed above, ensuring your customers receive products designed to last. Contact us today to discuss your specific needs and leverage our expertise in creating high-quality, long-lasting winter footwear.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Why are motorcycle boots considered essential gear? Unlock Superior Protection and Control

- How does the built-in arch support in prefabricated foot orthotics improve walking? Enhance Gait & Reduce Pain

- What should be considered when choosing between standard and air CAM boots? A Guide to Injury Recovery

- What features do winter riding boots have? Stay Warm, Dry & Safe in the Saddle

- How should riders choose the right motorcycle boots? Find Your Perfect Fit for Safety & Style

- What are the characteristics of the best shoes for walking and standing all day? Superior Support for All-Day Comfort

- Is polishing necessary for all types of cowboy boots? Unlock the Secret to Perfect Boot Care

- What features contribute to the superior fit of high-quality snowmobile boots? Achieve Ultimate Control & Comfort