My task is clear: act as a senior technical advisor and create a definitive guide on slip-resistant sole materials. The user isn't just asking "what" materials are used; they're implicitly asking "why" and "which is right for me?". I need to address both the surface and deep needs. My strategy is to be objective, synthesized, and focused on solutions. The tone must be authoritative yet empathetic. The output must be perfectly formatted and scannable for easy reading.

Here's my plan of action:

-

Deconstructing the task is the first priority. I'm not here to just repeat the information, but to offer insights. The user needs clear information, so I will prioritize a concise format and clear explanations.

-

I have to understand the core question that the user is really asking. They don't just want a list; they want to know how to choose the right material for their specific needs. I need to explain the benefits and trade-offs of each material so they can make an informed decision.

-

I'll synthesize the information from the references (which I see are the same) and expand on the basic descriptions. I'll structure the article to compare the materials and explain their properties.

-

My structure is key to success. I'll open with a bold hook that directly answers the "what" question. Then, I'll provide a concise summary of the core insight. The main body will delve into the materials, giving each its own heading and key properties, and then I'll create a "Trade-offs" section to ensure a well-rounded analysis. I'll wrap up with actionable advice, guiding the user to the right choice based on their specific situation.

-

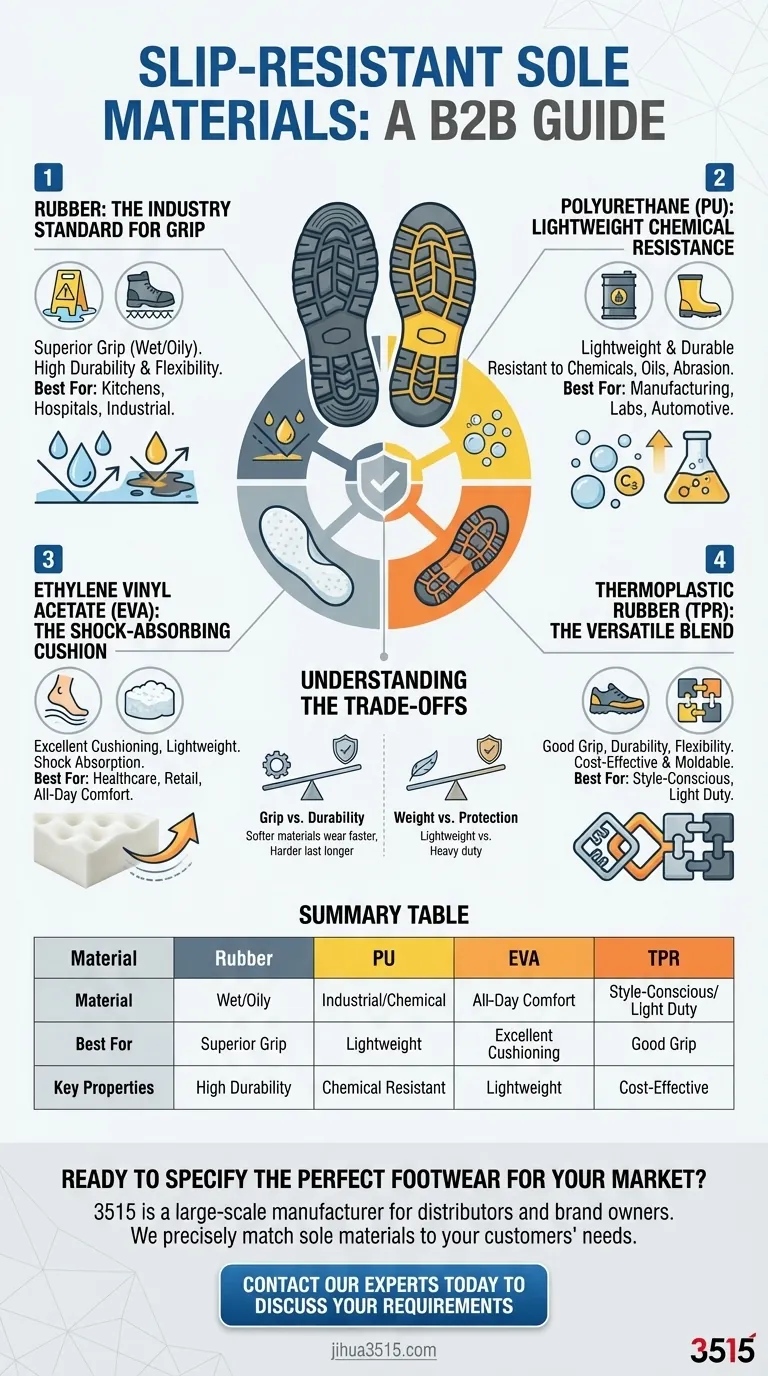

Reviewing is critical. I'll ensure the formatting is perfect: short paragraphs, clear headings, bold terms. The tone has to be objective and helpful. Most importantly, the structure must be well-organized and the conclusion direct and useful. I need to make sure the flow from "what" to "why" to "how to choose" is seamless. At its core, slip-resistant footwear relies on a specific set of materials designed for safety and performance. The most common materials used for these soles are Rubber, Polyurethane (PU), Ethylene Vinyl Acetate (EVA), and Thermoplastic Rubber (TPR). Each material is chosen for its unique combination of grip, durability, weight, and resistance to environmental factors like oil or chemicals.

The critical insight is that there is no single "best" material for a slip-resistant sole. The ideal choice is always a function of the specific environment, balancing factors like the type of surface, the need for comfort, and the required durability.

Deconstructing Slip-Resistant Materials

Understanding the core properties of each material is the key to selecting the right footwear. The choice directly impacts safety, comfort, and the longevity of the shoe.

Rubber: The Industry Standard for Grip

Rubber is a traditional and highly effective material for slip resistance, especially on wet and oily surfaces. Its high coefficient of friction provides an excellent grip.

This makes it the default choice for demanding environments like professional kitchens, hospitals, and industrial settings where spills are common. It is also highly durable and flexible.

Polyurethane (PU): Lightweight Chemical Resistance

Polyurethane soles are prized for being exceptionally lightweight and durable. This significantly reduces foot fatigue over long shifts.

PU also offers excellent resistance to chemicals, oils, and abrasion. This combination makes it ideal for manufacturing, laboratory, or automotive environments where exposure to various substances is a concern.

Ethylene Vinyl Acetate (EVA): The Shock-Absorbing Cushion

EVA is a foam-like material renowned for its superior shock absorption and cushioning properties. It is extremely lightweight and flexible, providing a high degree of comfort.

You will often find EVA in athletic footwear, but its comfort makes it a popular choice for healthcare and service professionals who spend all day on their feet. Its grip is effective but may be less robust on oily surfaces compared to rubber.

Thermoplastic Rubber (TPR): The Versatile Blend

TPR is a synthetic material that blends the properties of plastic and rubber. It offers a good balance of slip resistance, durability, and flexibility at a lower cost.

Because it can be easily molded, TPR is often used in more style-conscious or casual safety footwear where the demands for grip are moderate but comfort and aesthetics are also important.

Understanding the Trade-offs

Selecting a sole material always involves compromises. Understanding these trade-offs ensures you don't prioritize one feature at the expense of a more critical one.

Grip vs. Durability

Softer materials, which often provide the best initial grip, can wear down more quickly than harder, more durable compounds. A sole designed for maximum grip on an oily floor might not last as long as a harder PU sole designed for abrasion resistance.

Weight vs. Protection

While lightweight materials like EVA and PU reduce fatigue, they may offer less puncture resistance or thermal insulation than a thick, heavy rubber sole. The level of protection must be matched to the potential workplace hazards.

Cost and Specialization

High-performance, specialized rubber compounds formulated for specific chemical or oil resistance will typically be more expensive than general-purpose materials like TPR. The cost often reflects the level of specialized engineering and safety it provides.

Making the Right Choice for Your Environment

Your specific workplace hazard should be the primary factor guiding your decision.

- If your primary focus is maximum grip on wet or oily surfaces (e.g., kitchens, food processing): A high-grade rubber sole is the most reliable choice for safety.

- If your primary focus is all-day comfort and shock absorption (e.g., healthcare, retail): An EVA sole will provide the best cushioning to reduce fatigue from standing and walking.

- If your primary focus is durability and chemical resistance in an industrial setting (e.g., factories, labs): A polyurethane (PU) sole offers a superior blend of light weight and resilience.

- If your primary focus is a balance of moderate grip, comfort, and style for light duty: A thermoplastic rubber (TPR) sole provides a versatile and cost-effective solution.

Ultimately, matching the material's inherent strengths to your daily challenges is the most effective way to ensure both safety and comfort.

Summary Table:

| Material | Best For | Key Properties |

|---|---|---|

| Rubber | Wet/Oily Surfaces (Kitchens, Hospitals) | Superior Grip, High Durability, Flexibility |

| Polyurethane (PU) | Industrial/Chemical Settings | Lightweight, Chemical/Oil Resistant, Durable |

| EVA | All-Day Comfort (Healthcare, Retail) | Excellent Cushioning, Lightweight, Shock Absorption |

| Thermoplastic Rubber (TPR) | Style-Conscious & Light Duty | Good Grip, Cost-Effective, Versatile |

Ready to Specify the Perfect Slip-Resistant Footwear for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety and occupational footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, allowing us to precisely match the sole material—whether it's high-grip rubber, durable PU, cushioned EVA, or versatile TPR—to your customers' specific safety and comfort needs.

Let's collaborate to develop a footwear line that combines superior safety with market-leading value.

Contact our experts today to discuss your requirements

Visual Guide

Related Products

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

People Also Ask

- Why is proper fit crucial for safety toe boots? Avoid These Hidden Hazards

- What are the key considerations for finding a perfect fitting safety toe boot? Avoid Injury and Discomfort

- What is the most common shoe width for safety toe boots? The Critical Fit Guide for Comfort & Safety

- How can you determine the right safety toe boot for your workplace? Match Boots to Hazards

- Are safety shoes worth it? The Critical Investment in Workplace Safety & Foot Health