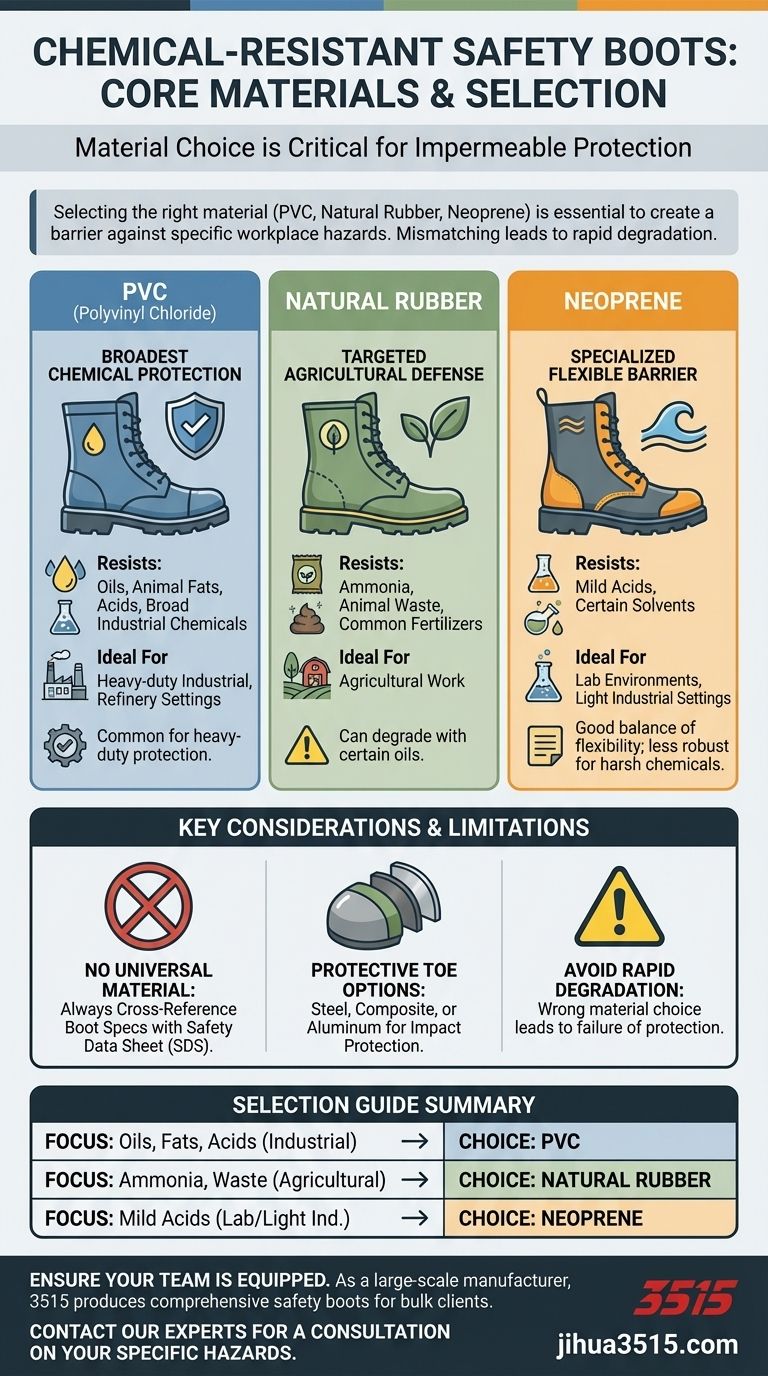

When selecting chemical-resistant safety boots, the choice of material is the single most critical factor for ensuring your protection. The industry standard materials are PVC (Polyvinyl Chloride), natural rubber, and neoprene, each chosen for its ability to create an impermeable barrier against specific corrosive and harmful substances found in hazardous work environments.

The decision between PVC, rubber, or neoprene is not about general durability but about matching the material's specific resistance profile to the exact chemical hazards you will face. Choosing the wrong material can lead to rapid degradation and a complete failure of protection.

A Closer Look at the Core Materials

Understanding the distinct advantages and weaknesses of each material is essential for making a safe and effective choice. The material of the boot's upper is your primary line of defense against chemical splashes and exposure.

PVC (Polyvinyl Chloride)

PVC is a synthetic plastic polymer renowned for its excellent chemical resistance, making it a common choice for heavy-duty protection.

Among the standard options, PVC generally offers the best and broadest chemical protection. It stands up well against oils, animal fats, acids, and many other industrial chemicals, preventing skin irritation or serious harm from accidental contact.

Natural Rubber

Natural rubber is a durable and flexible material that provides a reliable barrier against a more specific set of substances.

It is particularly effective against ammonia, animal waste, and common fertilizers. This makes it a frequent choice in agricultural settings. However, it can degrade when exposed to certain oils.

Neoprene

Neoprene is a type of synthetic rubber that offers a good balance of flexibility and targeted chemical resistance.

Its primary strength lies in its resistance to mild acids and certain solvents. While effective in these applications, it is generally considered less robust against the harsher or more complex chemicals that PVC can handle.

Understanding the Trade-offs and Limitations

A safety boot is a system, and its effectiveness depends on more than just one feature. Acknowledging the limitations of each material is key to ensuring comprehensive safety.

No Single Material is Universal

There is no "one-size-fits-all" boot for every chemical hazard. A boot that is highly resistant to acids might offer poor protection against petroleum-based solvents.

Always cross-reference the boot's specifications with the Safety Data Sheet (SDS) for the chemicals present in your workplace. This is the only way to confirm a proper match.

Beyond the Boot: Protective Toe Options

While the boot's primary material protects against chemical splashes, impact protection is also a critical safety consideration.

Many chemical-resistant boots incorporate protective toe caps, which can be made of steel, composite materials, or aluminum. Each offers a different balance of weight, impact resistance, and comfort, adding another layer to your selection criteria.

How to Select the Right Boot for Your Environment

Your specific work environment and the hazards within it should be the only guide for your final decision.

- If your primary focus is broad chemical protection, especially against oils, fats, and acids: PVC is often the most robust and reliable choice for industrial or refinery settings.

- If your primary focus is agricultural work with exposure to ammonia and waste: Natural rubber provides targeted and effective resistance for these specific hazards.

- If your primary focus is working with mild acids in a lab or light industrial setting: Neoprene offers a suitable level of specialized protection without unnecessary bulk.

Making an informed material choice is the foundation of ensuring your chemical safety on the job.

Summary Table:

| Material | Key Chemical Resistance | Ideal For |

|---|---|---|

| PVC | Oils, fats, acids, broad industrial chemicals | Heavy-duty industrial, refinery settings |

| Natural Rubber | Ammonia, animal waste, fertilizers | Agricultural work |

| Neoprene | Mild acids, certain solvents | Lab environments, light industrial settings |

Ensure your team is equipped with the right chemical-resistant footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of chemical-resistant footwear, ensuring you get the precise protection your workforce needs.

Contact our experts today for a consultation on the best safety boots for your specific chemical hazards.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What is the function of the shank in a safety boot? The Key to Arch Support & Stability

- What role does an industrial-grade heat setting oven play in the bonding of the safety shoe upper and sole?

- How does S3 protection differ from S2? Matching Safety Footwear to Your Work Hazards

- What are the functional benefits of high-grade protective footwear for logistics? Maximize Efficiency in Cold Storage

- What role does IoT technology play in safety shoe production? Powering Digital Precision & Efficiency

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- Can firefighter boots be resoled? A Guide to Safe & Cost-Effective Repair

- What roles do professional safety shoes play in furniture manufacturing? Maximize Safety & Workshop Performance