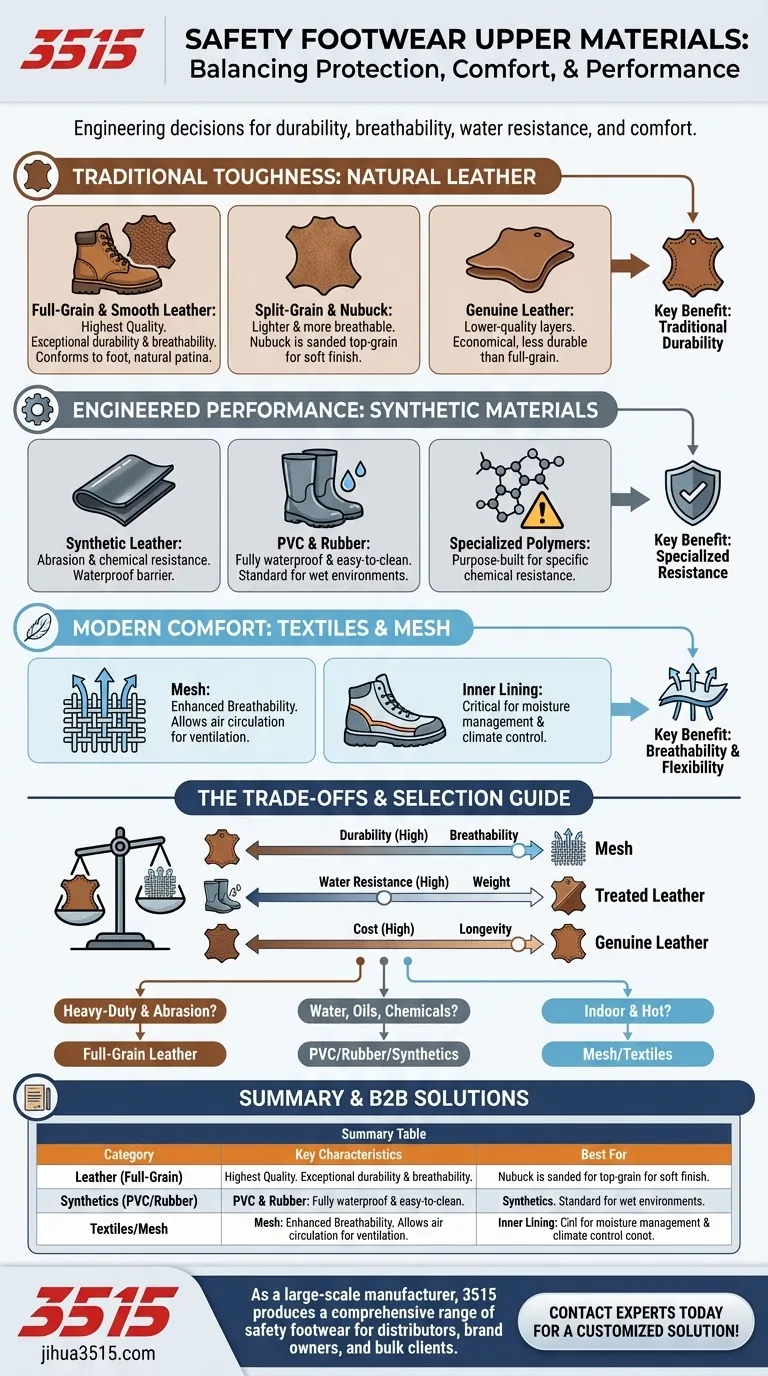

The upper part of safety footwear is constructed from a range of materials, primarily falling into three categories: natural leather, synthetic materials, and textiles. The specific material is chosen to meet the demands of a particular work environment, balancing critical factors like durability, breathability, water resistance, and wearer comfort.

The choice of an upper material is not arbitrary; it's a deliberate engineering decision. Leather offers traditional durability, synthetics provide specialized resistance to chemicals and water, and textiles deliver modern breathability and flexibility. Understanding the trade-offs between these options is key to selecting the right protection.

The Role of Leather in Safety Footwear

Leather has long been the traditional material for work boots due to its unique combination of toughness and comfort. Different grades and types of leather offer distinct advantages.

Full-Grain and Smooth Leather

This is the highest quality leather, known for its exceptional durability, breathability, and moisture-wicking properties. It conforms to the foot over time and develops a natural patina, often lasting longer than other materials.

Split-Grain and Nubuck Leather

Split-grain leather is created from the lower layers of the hide, making it lighter and more breathable than full-grain. Nubuck is a top-grain leather that has been sanded to create a soft, suede-like finish, offering a balance of comfort and toughness.

Genuine Leather

While the name sounds premium, "genuine leather" typically refers to lower-quality layers of the hide. It is a more economical option but lacks the long-term durability and performance of full-grain or top-grain leather.

The Rise of Synthetic Materials

Modern synthetic materials are engineered to provide specific performance characteristics that natural leather cannot always match, especially in harsh or specialized environments.

Synthetic Leather

This material offers excellent abrasion and chemical resistance. It is also frequently used for its waterproofing capabilities, providing a consistent barrier against moisture.

PVC and Rubber

For environments with significant exposure to water, mud, or certain chemicals, PVC (polyvinyl chloride) and rubber are the standard. These materials create a fully waterproof and easy-to-clean shell.

Specialized Polymers

In highly specific industries, uppers are made from purpose-built, chemical-resistant polymers. These are designed to protect against particular hazardous substances where general-purpose materials would fail.

Textiles and Mesh for Modern Comfort

To meet the demand for lighter and more comfortable safety footwear, manufacturers increasingly incorporate textiles and mesh into the upper construction.

Enhanced Breathability and Flexibility

Mesh is a woven material prized for its ability to allow air to circulate, significantly improving ventilation and reducing heat buildup. This makes it ideal for indoor work or hot climates where breathability is a priority.

The Importance of the Inner Lining

The material inside the footwear, or the lining, is just as critical as the outer material. Linings made of leather, thermo-regulating textiles, or waterproof membranes work to manage moisture, control climate, and resist abrasion from the inside.

Understanding the Trade-offs

No single material is perfect for every application. Selecting the right footwear requires a clear understanding of the compromises involved.

Durability vs. Breathability

The toughest materials, like full-grain leather, offer maximum protection against abrasion but can be less breathable than lightweight textiles or mesh. The choice depends on whether the primary risk is physical impact or heat fatigue.

Water Resistance vs. Weight

Materials like PVC and rubber are completely waterproof but are often heavier and less breathable. In contrast, treated leathers and synthetic membranes offer water resistance in a lighter, more comfortable package.

Cost vs. Longevity

High-end materials like full-grain leather come with a higher initial cost but often last significantly longer, providing better value over time. Less expensive synthetic or genuine leather options may need to be replaced more frequently.

Making the Right Choice for Your Environment

Your work environment is the ultimate guide to selecting the appropriate upper material. A clear assessment of your daily tasks and risks will lead you to the best option.

- If your primary focus is heavy-duty durability and abrasion resistance: Full-grain leather is the unmatched choice for demanding jobs in construction, manufacturing, or farming.

- If your primary focus is protection from water, oils, or chemicals: Footwear with uppers made of PVC, rubber, or specialized synthetic polymers is non-negotiable.

- If your primary focus is lightweight comfort and breathability in a dry, indoor setting: Safety shoes with significant mesh panels or textile uppers will provide the best all-day comfort.

Understanding these material properties empowers you to select footwear that doesn't just protect your feet, but actively enhances your performance and safety on the job.

Summary Table:

| Material Category | Key Characteristics | Best For |

|---|---|---|

| Leather (Full-Grain) | Maximum durability, breathability | Heavy-duty construction, manufacturing |

| Synthetics (PVC/Rubber) | Waterproof, chemical-resistant | Wet environments, chemical handling |

| Textiles/Mesh | Lightweight, highly breathable | Indoor work, hot climates |

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the right material and protection for your specific needs. Let us help you enhance workplace safety and comfort. Contact our experts today for a customized solution!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites