In vulcanized footwear production, the definitive material choice for lasts is aluminum. This is not an arbitrary selection but a fundamental requirement dictated by the manufacturing process itself, which involves subjecting the entire shoe to intense heat and pressure to cure and bond the rubber components.

The use of aluminum for vulcanizing lasts is a solution to a thermal engineering problem, not just a shoemaking one. The material must not only survive the high-temperature "oven" but also actively participate by conducting heat evenly to ensure a uniform and durable final product.

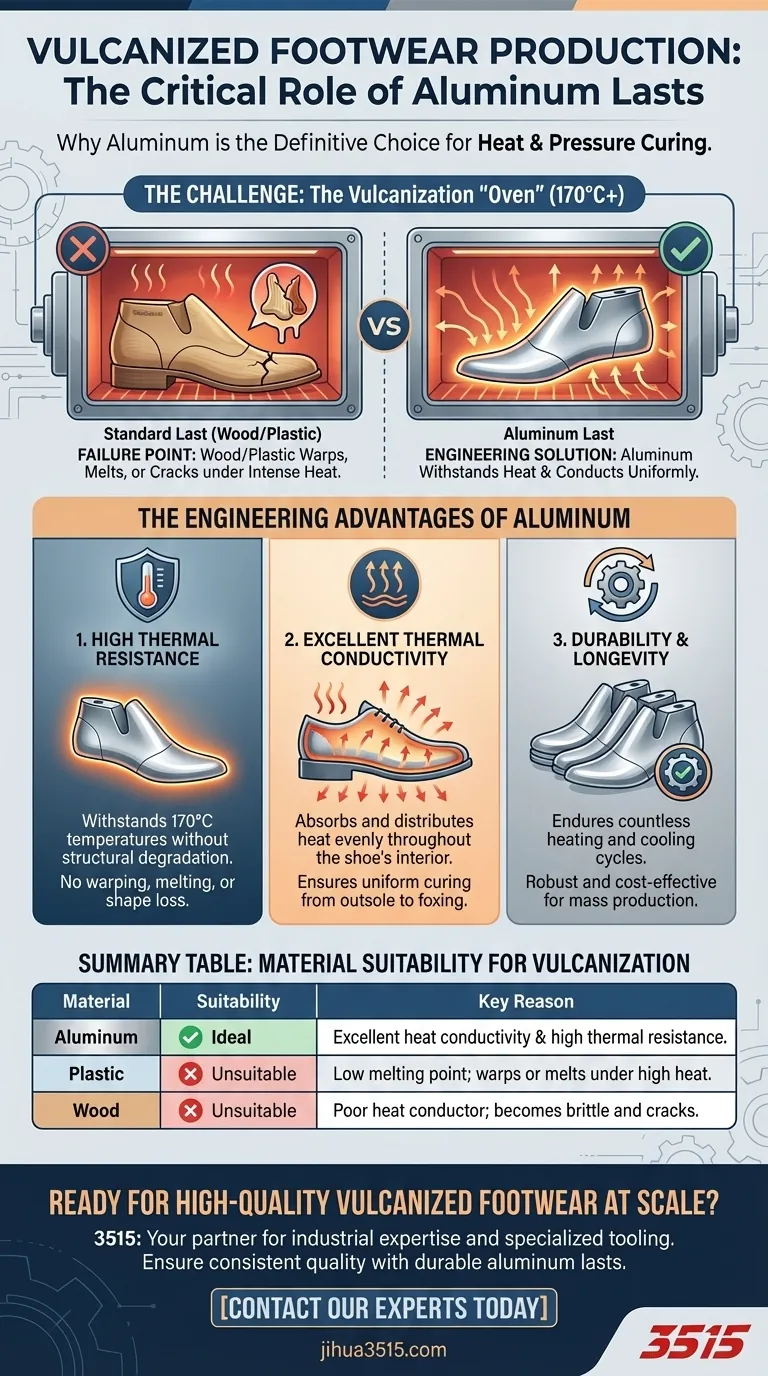

Why Standard Lasts Are Unsuitable

Traditional shoe lasts made from wood or plastic are perfectly adequate for standard manufacturing methods like cemented or stitched construction. However, they fail completely when subjected to the vulcanization process.

The Failure Point of Plastic

Most plastics used for shoe lasts have a low melting point. The high temperatures required for vulcanization, often around 170°C (338°F), would cause a plastic last to soften, warp, or melt entirely, destroying both the last and the shoe.

The Limitations of Wood

Wood cannot withstand repeated cycles of intense heat. It would dry out, become brittle, and eventually crack or scorch inside the vulcanizing chamber. Furthermore, wood is a poor conductor of heat, which would prevent the shoe from curing evenly.

The Unique Demands of Vulcanization

To understand why aluminum is the only viable choice, it's essential to understand the core principles of vulcanizing a shoe.

An Industrial Oven

The process involves placing a nearly assembled shoe, with its uncured rubber components, onto the last and putting the entire assembly into a high-temperature chamber or autoclave.

Heat as a Bonding Agent

This intense heat initiates a chemical reaction in the rubber, cross-linking its polymers. This "curing" process transforms the soft, gummy rubber into the firm, durable, and elastic material we associate with sneaker outsoles.

The Critical Need for Uniformity

For the bond between the rubber outsole and the shoe's upper to be strong and consistent, every part of the shoe must reach the correct temperature for the right amount of time. Uneven heating would result in weak spots, uncured sections, and a defective product.

The Engineering Advantages of Aluminum

Aluminum possesses a specific set of properties that make it uniquely suited to solve the challenges of vulcanization.

High Thermal Resistance

First and foremost, aluminum can easily withstand the 170°C temperatures of the vulcanization process without losing its structural integrity. It will not warp, melt, or degrade, ensuring the shoe's shape is perfectly maintained throughout the heating cycle.

Excellent Thermal Conductivity

This is the most crucial factor. Aluminum is an excellent heat conductor. It absorbs heat from the vulcanizing chamber and distributes it evenly throughout the inside of the shoe. This ensures that the entire assembly cures at a uniform rate, from the thickest part of the outsole to the thin rubber foxing tape along the sides.

Durability and Longevity

Aluminum lasts are extremely durable and can endure countless cycles of heating and cooling. This robustness makes them a long-lasting and cost-effective tool for the repetitive nature of mass footwear production.

Making the Right Choice for Your Process

The material science of your tooling is dictated entirely by the demands of your manufacturing process.

- If your primary focus is a heat-based curing process (like vulcanization): Your tooling material must be chosen for its thermal resistance and conductivity to ensure a uniform product.

- If your primary focus is a cold-assembly process (like cement construction): You can prioritize lower-cost, easily-shaped materials like plastic or wood, as thermal properties are irrelevant.

Ultimately, the aluminum last is not just a form to build a shoe on; it is an active thermal tool essential to the success of the vulcanization reaction.

Summary Table:

| Material | Suitability for Vulcanization | Key Reason |

|---|---|---|

| Aluminum | Ideal | Excellent heat conductivity and high thermal resistance. |

| Plastic | Unsuitable | Low melting point; warps or melts under high heat. |

| Wood | Unsuitable | Poor heat conductor; becomes brittle and cracks. |

Ready to produce high-quality vulcanized footwear at scale?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities, including specialized tooling like durable aluminum lasts, ensure consistent quality and durability for every pair.

Contact our experts today to discuss your vulcanized footwear production needs and benefit from our industrial expertise.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene