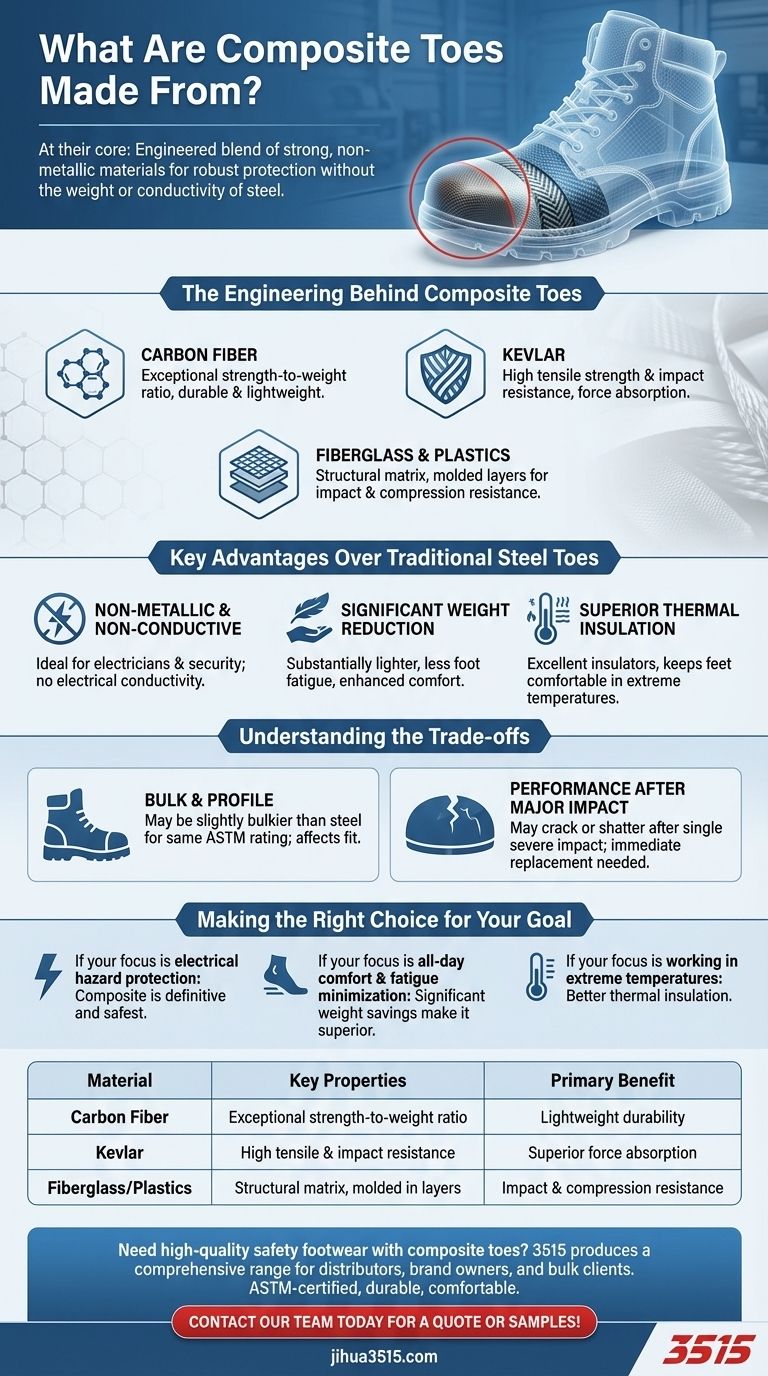

At their core, composite safety toes are engineered from a blend of strong, non-metallic materials designed to provide robust protection without the weight and conductivity of steel. The most common materials used in their construction include Kevlar, carbon fiber, fiberglass, and specialized plastics.

Composite safety toes leverage advanced, non-metal materials to meet rigorous safety standards while offering significant advantages in weight, electrical conductivity, and thermal insulation compared to traditional steel toes.

The Engineering Behind Composite Toes

The term "composite" refers to a material made from two or more constituent materials with significantly different physical or chemical properties which, when combined, produce a material with characteristics different from the individual components. This principle is central to the performance of a composite safety toe.

Carbon Fiber

Carbon fiber is known for its incredible strength-to-weight ratio. It consists of microscopic crystalline filaments of carbon, making it exceptionally strong and rigid for its low density. This allows for a protective toe cap that is both durable and lightweight.

Kevlar

Kevlar is a high-strength synthetic fiber, famous for its use in ballistic and stab-resistant body armor. Its inclusion in a composite toe cap provides immense tensile strength and impact resistance, helping to absorb and dissipate the force from a sudden blow.

Fiberglass and Plastics

Fiberglass and advanced plastics often form the structural matrix of the composite toe. These materials are molded in layers, binding the stronger fibers like carbon fiber or Kevlar together into a solid, protective shell that can withstand compression and impact.

Key Advantages Over Traditional Steel Toes

Choosing a composite toe is often a deliberate decision based on the unique demands of a work environment. The benefits extend beyond simple impact protection.

Non-Metallic and Non-Conductive

Because they contain no metal, composite toes are ideal for electricians or workers in high-security environments with metal detectors. They do not conduct electricity, providing a critical layer of protection against electrical hazards.

Significant Weight Reduction

Composite materials are substantially lighter than steel. This reduction in weight translates directly to less foot fatigue over a long workday, enhancing comfort and reducing strain on the wearer.

Superior Thermal Insulation

Unlike steel, which readily conducts heat and cold, composite materials are excellent insulators. This keeps feet more comfortable in both extreme hot and cold working conditions.

Understanding the Trade-offs

While offering many advantages, it's important to understand the practical differences in performance when selecting safety footwear. Objectivity is key to making the safest choice.

Bulk and Profile

To achieve the same ASTM safety rating for impact and compression, a composite toe cap may need to be slightly bulkier than its steel counterpart. This can affect the fit and overall profile of the work boot.

Performance After Major Impact

This is a critical distinction. After a single, severe impact that exceeds its rating, a composite toe may crack or shatter. While it will have protected the foot in that event, the footwear must be replaced immediately. Steel, by contrast, may bend but remain intact, though it too should be replaced after a significant impact.

Making the Right Choice for Your Goal

Selecting the appropriate safety toe depends entirely on the primary hazards and demands of your specific role.

- If your primary focus is electrical hazard protection: Composite toes are the definitive and safest choice, as they are non-conductive.

- If your primary focus is all-day comfort and minimizing fatigue: The significant weight savings of a composite toe make it the superior option.

- If your primary focus is working in extreme temperatures: Composite materials provide far better thermal insulation against heat and cold.

Understanding the materials inside your safety footwear empowers you to choose the right tool for the job.

Summary Table:

| Material | Key Properties | Primary Benefit |

|---|---|---|

| Carbon Fiber | Exceptional strength-to-weight ratio | Lightweight durability |

| Kevlar | High tensile & impact resistance | Superior force absorption |

| Fiberglass/Plastics | Structural matrix, molded in layers | Impact & compression resistance |

Need high-quality safety footwear with composite toes?

As a large-scale manufacturer, 3515 produces a comprehensive range of composite toe boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, comfortable, and ASTM-certified footwear tailored to your market's needs.

Let's discuss your specific requirements — contact our team today to get a quote or request samples!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- Why are fully covered protective shoes recommended over open-toe footwear for diabetic foot ulcers? Critical for Safety & Prevention

- How does the selection of high-performance materials impact the effectiveness of protective footwear? Key Benefits Explained

- What are the key differences between EN ISO 20345 and EN ISO 20347 certifications? Choose the Right Footwear for Your Workplace Safety

- What are metatarsal shoes? Essential Foot Protection for High-Risk Work

- What role does PPE and safety footwear play in high-risk construction? Secure Your Workforce with Final Line Defense

- What are the advantages of 3D digital twin models over 2D images for safety shoes? Boost Confidence with AR & 3D Tech

- What is the benefit of using Fluoroalkylsilane (FAS) for safety shoe fabrics? Enhance Oil and Water Repellency

- What materials are used to make safety toes? Choose the Right Protection for Your Job