The upper construction of tactical boots primarily utilizes a combination of full-grain leather, synthetic leather, ballistic nylon, and mesh panels. These materials are chosen for their specific properties, balancing durability, protection, weight, and breathability to meet the demanding requirements of various operational environments.

The selection of upper materials for tactical boots is a critical design decision, directly impacting the boot's durability, protective qualities, and wearer comfort. Effective material combinations prioritize ruggedness and support while strategically incorporating elements for breathability and reduced weight, catering to the diverse needs of tactical professionals.

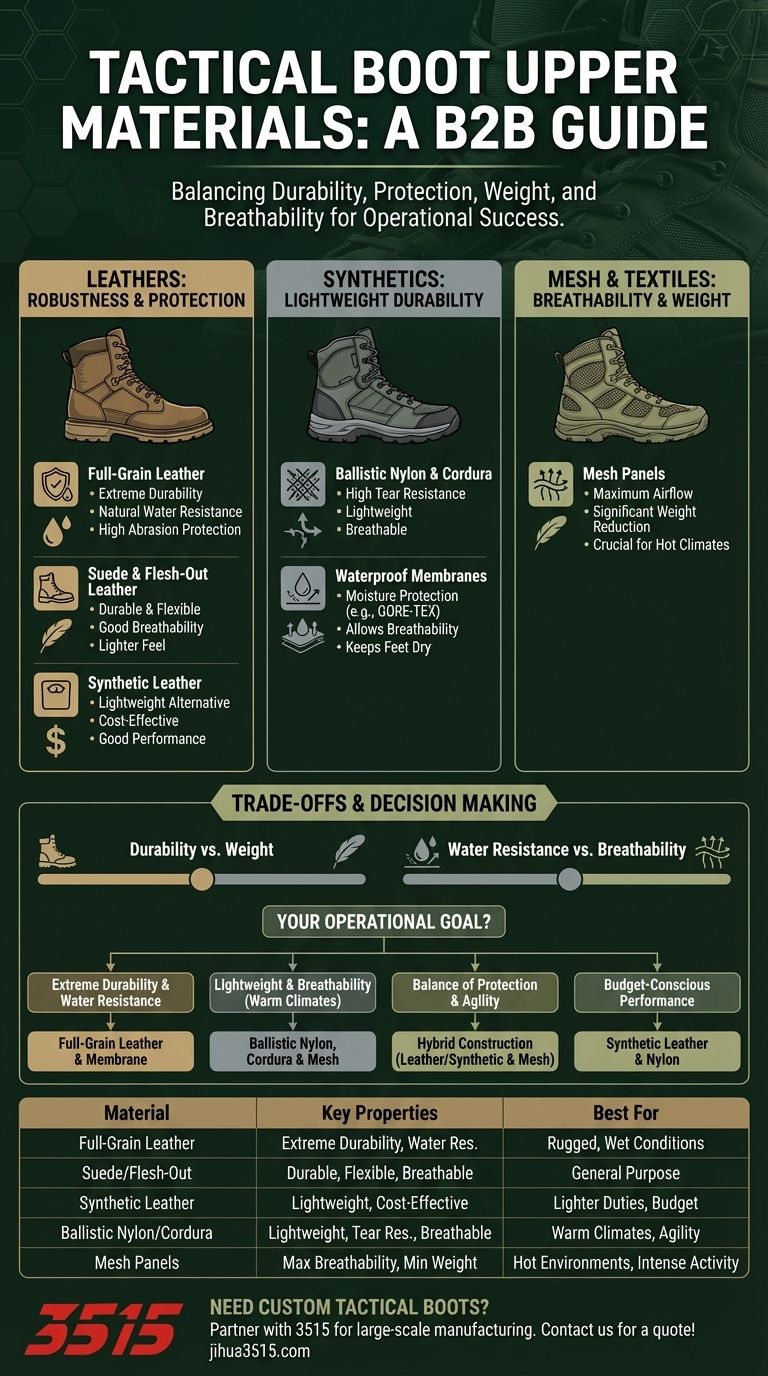

Understanding Common Upper Materials

Tactical boots are engineered to perform in challenging conditions, making the choice of upper materials crucial. These materials dictate a boot's resilience, comfort, and suitability for different climates and tasks.

Leathers for Robustness and Protection

Leather remains a foundational material for tactical boot uppers due to its inherent strength and protective qualities. Different types offer distinct advantages.

Full-Grain Leather

Full-grain leather is highly valued for its exceptional durability, ruggedness, and natural water resistance. It provides excellent abrasion protection and, when properly cared for, can age very well, becoming more comfortable over time.

Suede and Flesh-Out Leather

Suede leather is durable, flexible, and offers good breathability, often feeling lighter than full-grain options. Similarly, flesh-out leather is known for its durability and can be quite robust.

Synthetic Leather

Synthetic leather provides a lightweight and cost-effective alternative to natural leather. While it can offer good performance, it is generally considered less durable than full-grain leather.

Synthetics for Lightweight Durability

Modern synthetic materials have revolutionized tactical boot design, offering high performance with reduced weight. These materials enhance specific functional aspects like breathability and tear resistance.

Ballistic Nylon and Cordura

Ballistic nylon is lightweight, highly resistant to tearing and abrasions, and offers good breathability. CORDURA is a similar type of durable nylon-cotton blend known for its exceptional strength and abrasion resistance, making it ideal for rugged applications.

Mesh and Textiles for Breathability

Incorporating mesh panels and other textiles is key to improving comfort, particularly in warm environments. These elements ensure proper airflow and reduce overall boot weight.

Mesh Panels

Mesh panels are frequently integrated into boot uppers to enhance airflow and improve breathability. This makes them crucial for maintaining comfort in hot conditions and for reducing the boot's overall weight.

Waterproof Membranes

While not an external upper material, waterproof membranes like GORE-TEX are often laminated beneath the primary upper materials. They provide an essential layer for moisture protection while still allowing some breathability, keeping feet dry in wet conditions.

Understanding the Trade-offs

Material selection in tactical boot construction always involves balancing competing performance characteristics. No single material offers a perfect solution for every scenario.

Balancing Durability and Weight

Heavier, more durable materials like full-grain leather offer superior protection and longevity but increase overall boot weight. Lighter synthetics and mesh reduce weight, improving agility, but may compromise ultimate durability.

Water Resistance Versus Breathability

Materials with high water resistance, such as full-grain leather and waterproof membranes, can limit air circulation. Highly breathable materials like mesh panels, conversely, offer less protection against water penetration.

Cost and Performance Considerations

More advanced, durable, and protective materials often come at a higher cost. Budget-friendly options, such as synthetic leather, may offer a good balance but might not match the extreme performance of premium materials.

Making the Right Choice for Your Goal

Selecting the ideal tactical boot material depends entirely on the specific demands of your operational environment and primary mission.

- If your primary focus is extreme durability and water resistance: Prioritize boots with robust full-grain leather uppers and integrated waterproof membranes.

- If your primary focus is lightweight performance and breathability in warm climates: Opt for boots that extensively use ballistic nylon, CORDURA, and large mesh panels.

- If your primary focus is a balance of protection and agility for varied conditions: Look for a hybrid construction featuring a mix of durable leather or high-performance synthetics combined with strategic mesh ventilation.

- If your primary focus is budget-consciousness with reasonable performance: Consider boots that incorporate quality synthetic leather and nylon for a cost-effective solution.

Understanding the properties and trade-offs of upper materials empowers you to choose tactical boots that are truly fit for purpose, optimizing performance and comfort in the field.

Summary Table:

| Material | Key Properties | Best For |

|---|---|---|

| Full-Grain Leather | Extreme durability, water resistance, abrasion protection | Rugged environments, wet conditions |

| Suede/Flesh-Out Leather | Durability, flexibility, breathability | General-purpose use, good comfort |

| Synthetic Leather | Lightweight, cost-effective | Budget-conscious buyers, lighter duties |

| Ballistic Nylon/Cordura | Lightweight, high tear resistance, breathable | Warm climates, missions requiring agility |

| Mesh Panels | Maximum breathability, minimal weight | Hot environments, intense physical activity |

Need Tactical Boots Built for Your Specific Requirements?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of tactical boots, from ultra-durable leather constructions to lightweight nylon and mesh designs.

We can help you:

- Develop custom tactical boots tailored to your operational environment and performance needs.

- Source high-quality materials to achieve the perfect balance of durability, protection, and comfort.

- Benefit from large-scale manufacturing efficiency for competitive pricing and reliable supply.

Let's discuss your project. Contact our expert team today to get a quote and learn how we can be your trusted tactical boot manufacturing partner.

Visual Guide

Related Products

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

People Also Ask

- What are some Salomon boots used by Bravo and their features? Elite Footwear for Demanding Missions

- What materials should be prioritized for durable tactical boots? Select the Right Materials for Maximum Longevity

- How do high-performance training shoes and tactical boots enhance emergency evacuation performance? Optimize Your Safety

- Why is conditioning important for full grain leather tactical boots? Prevent Cracking & Ensure Longevity

- What should outdoor enthusiasts look for in tactical boots? Find the Perfect Balance of Traction & Support

- What should firefighters and EMTs consider when choosing tactical boots? Balance Safety, Comfort & Performance

- What is the purpose of the rigid plastic box in smart insoles? Protecting Electronics in Tactical Footwear

- What is a composite shank, and how does it benefit tactical boots? Boost Agility and Comfort