The short answer is that military camouflage boots are constructed from a strategic combination of materials, primarily using durable leather for the upper structure, breathable nylon fabric for ventilation, and high-traction rubber or polyurethane for the soles. This blend is engineered to balance protection, comfort, and performance across demanding operational environments.

The specific materials used in a military boot are not arbitrary; they represent a series of deliberate engineering trade-offs. The goal is to create footwear that can withstand extreme abuse while keeping the soldier's feet dry, supported, and functional in a specific climate.

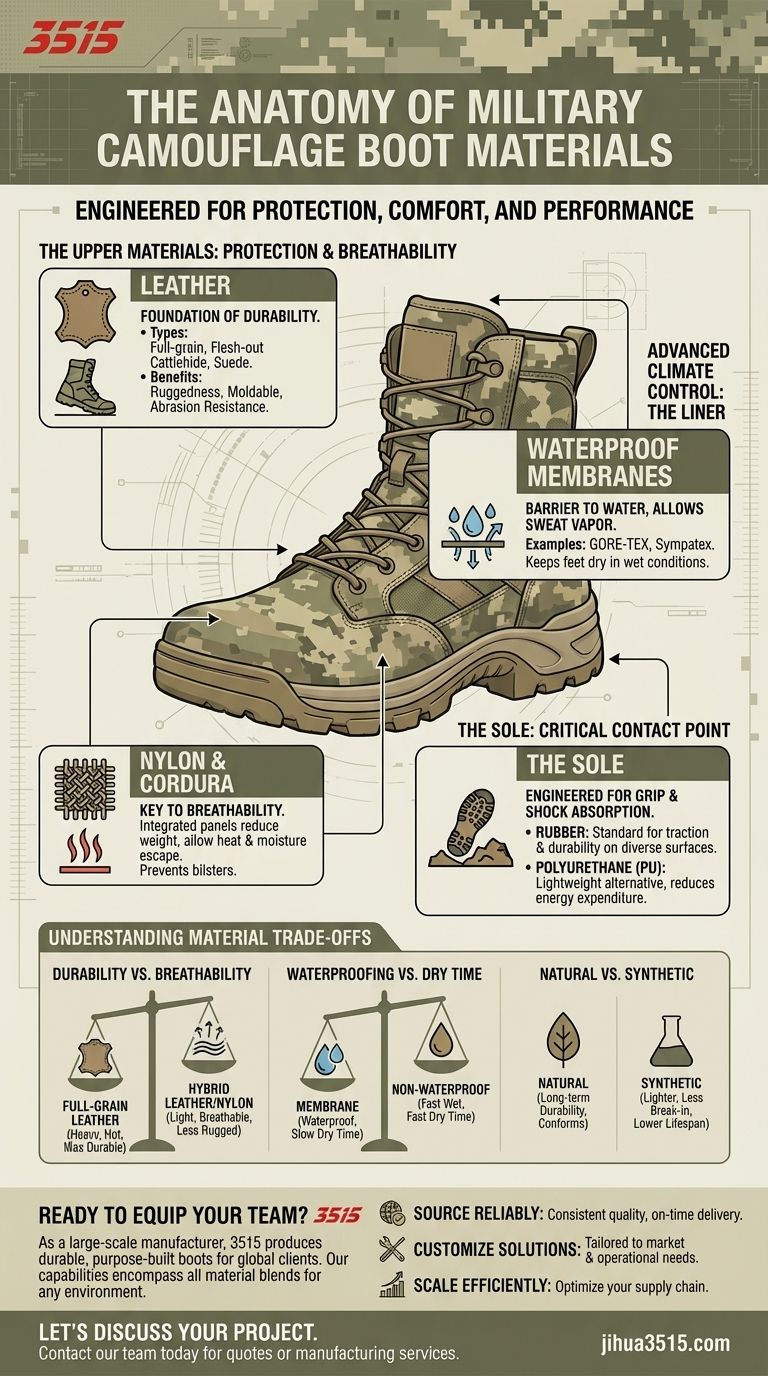

Deconstructing the Boot: The Upper Materials

The upper section of the boot is what protects the foot from the elements, impacts, and abrasions. The choice of material here directly impacts the boot's weight, durability, and breathability.

Leather: The Foundation of Durability

Leather is the traditional cornerstone of military footwear for its exceptional toughness and moisture resistance.

Common types include full-grain leather or flesh-out cattlehide, prized for their ruggedness and ability to mold to the wearer's foot over time.

Suede or velour leather is also used, offering good durability with slightly more flexibility and breathability than its full-grain counterpart.

Nylon & Cordura: The Key to Breathability

To reduce weight and improve performance in warm climates, leather is often paired with rugged textile panels.

Nylon and similar fabrics like Cordura are integrated into the upper. These materials are lightweight and allow heat and moisture to escape, which is critical for preventing blisters and discomfort.

Waterproof Membranes: Advanced Climate Control

For operations in wet conditions, many modern boots incorporate a specialized waterproof-breathable membrane.

Liners made from GORE-TEX or Sympatex act as a barrier to external water while still allowing sweat vapor to pass through, keeping the foot dry from both rain and perspiration.

The Sole: The Critical Point of Contact

The sole of a military boot is engineered for grip, shock absorption, and stability on unpredictable terrain.

Rubber: The Standard for Grip

Rubber is the most common material for outsoles due to its excellent traction on diverse surfaces, from wet rocks to loose dirt. It is also highly durable and provides significant shock absorption to reduce fatigue.

Polyurethane: A Lightweight Alternative

Polyurethane (PU) is a modern synthetic material also used for soles. Its primary advantage is its lighter weight compared to traditional rubber, which can reduce the energy expenditure of the wearer over long distances.

Understanding the Trade-offs

The ideal boot doesn't exist; every material choice is a compromise designed for a specific purpose.

Durability vs. Breathability

A boot made entirely of full-grain leather offers maximum durability and protection but can be heavy and hot.

In contrast, a leather and nylon hybrid boot sacrifices some of that ruggedness for a significant increase in breathability and a reduction in weight, making it far more suitable for desert or jungle environments.

Waterproofing vs. Dry Time

A boot with a GORE-TEX membrane is excellent at keeping water out, but if it does get completely submerged, it can take a very long time to dry.

A non-waterproof boot made of suede and nylon will get wet much faster but will also dry out much more quickly, a critical factor in consistently humid or tropical climates.

Natural vs. Synthetic Materials

Natural leather offers unmatched long-term durability and the ability to conform to the foot.

Synthetic leathers and textiles are often lighter and require less break-in time but may not offer the same lifespan or abrasion resistance as their natural counterparts under heavy use.

Making the Right Choice for Your Goal

- If your primary focus is maximum durability and protection for temperate climates: Choose boots constructed primarily from full-grain leather.

- If your primary focus is performance in hot, dry environments: Prioritize boots with a suede leather and nylon/Cordura hybrid upper for superior breathability.

- If your primary focus is operating in consistently wet or cold conditions: Look for boots that incorporate a dedicated waterproof membrane like GORE-TEX and have a robust rubber sole for traction.

Ultimately, understanding these core materials empowers you to see a military boot not just as footwear, but as a piece of purpose-built technical equipment.

Summary Table:

| Material | Primary Use | Key Characteristic |

|---|---|---|

| Leather | Upper | Durability, abrasion resistance, protection |

| Nylon/Cordura | Upper Panels | Lightweight, breathable, quick-drying |

| Rubber/Polyurethane | Sole | Superior traction, shock absorption, durability |

| GORE-TEX | Liner | Waterproof, yet breathable membrane |

Ready to Equip Your Team with High-Performance Tactical Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and purpose-built military and tactical boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of footwear, engineered with the precise material blends detailed above to meet the demands of any environment.

We help you:

- Source Reliably: Get consistent quality and on-time delivery for your orders.

- Customize Solutions: Develop boots tailored to your specific market needs and operational requirements.

- Scale Efficiently: Benefit from our large-scale manufacturing expertise to optimize your supply chain.

Let's discuss your project. Contact our team today to request a quote or learn more about our manufacturing services.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- Why are comfort and support crucial in military boots? They are Mission-Critical for Soldier Performance.

- How do motorcycle boots differ from regular work boots? Understand the Critical Safety Gap

- What historical event marked the first use of camouflage in military apparel? The Napoleonic Wars' Tactical Shift

- How are combat boots designed and constructed? For Uncompromising Durability and Protection

- What materials are used in the construction of these boots? A Guide to Velour Leather, Textile & PU Soles

- What are the general characteristics of combat boots? Essential Features for Maximum Durability & Protection

- Can jungle boots be used in temperate climates? Maximize Comfort in Warm, Wet Conditions

- What are some regular maintenance tips for military boots? Maximize Lifespan & Performance