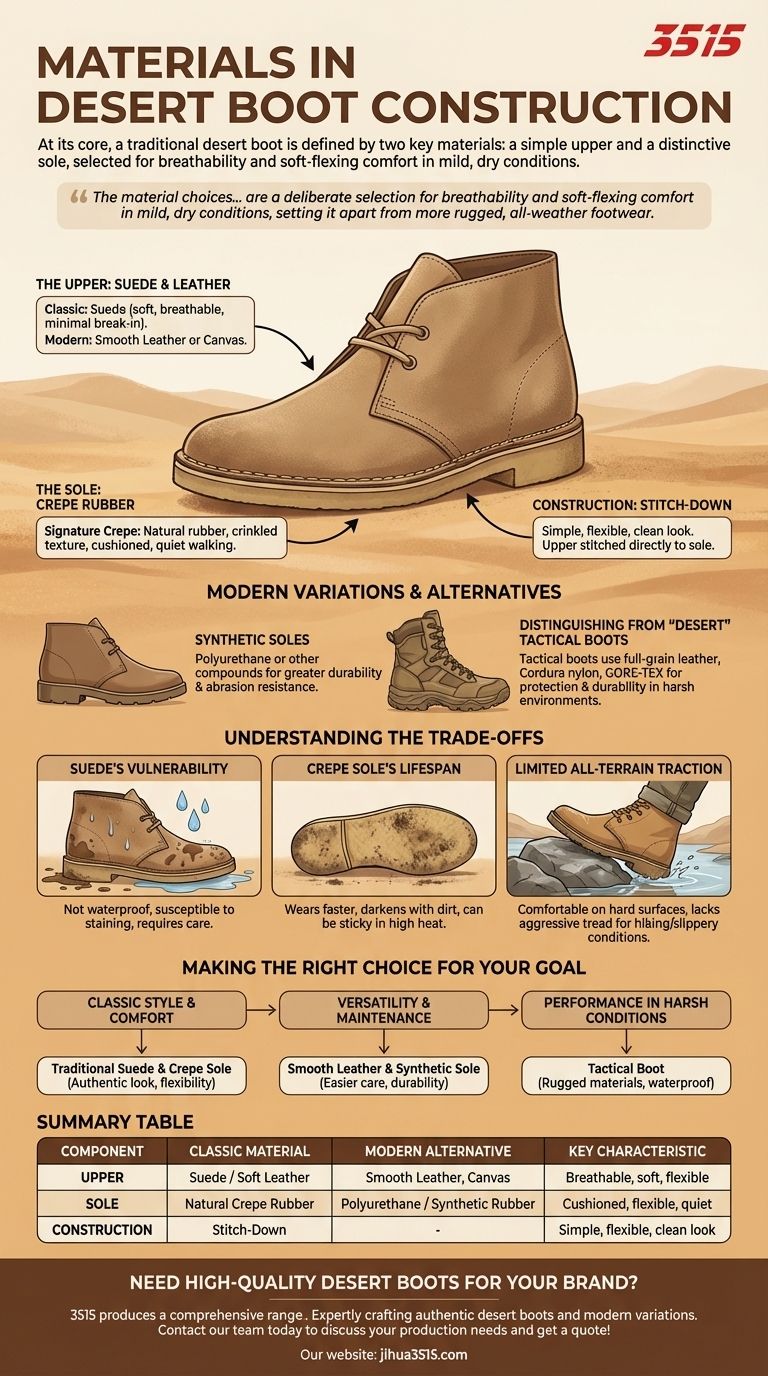

At its core, a traditional desert boot is defined by two key materials: a simple upper made of suede or soft leather, and a distinctive sole made from natural crepe rubber. This combination is what gives the boot its signature comfort, flexibility, and timeless style.

The material choices in a desert boot are not accidental; they are a deliberate selection for breathability and soft-flexing comfort in mild, dry conditions, setting it apart from more rugged, all-weather footwear.

The Anatomy of a Classic Desert Boot

To understand the desert boot, we must look at the specific function of its two primary components: the upper and the sole.

The Upper: Suede and Leather

The most iconic desert boots feature an upper made from suede. This material, which is leather with a napped finish, is chosen for its softness and breathability.

Unlike the rigid, full-grain leather found on heavy-duty work boots, suede is pliable and conforms easily to the foot, requiring minimal break-in time.

Modern interpretations may also use smooth leather for a different aesthetic or canvas for a lighter, more casual warm-weather option.

The Sole: The Signature Crepe Rubber

The sole is arguably the boot's most defining feature. It is traditionally made of crepe, a natural rubber with a unique, crinkled texture.

This material acts as a natural shock absorber, providing a cushioned, comfortable, and remarkably quiet walking experience. It is produced from coagulated latex, giving it a distinct softness and flexibility.

Construction: How It's All Held Together

The simple design is often held together with a stitch-down construction. This method, where the upper is turned outward and stitched directly to the sole, enhances the boot's flexibility and contributes to its clean, uncluttered appearance.

Modern Variations and Alternatives

While the classic formula remains popular, material choices have evolved to meet different demands for durability and function.

Synthetic Soles

Many modern desert boots now feature soles made from polyurethane or other synthetic rubber compounds. These materials often offer greater durability and abrasion resistance compared to traditional crepe.

Distinguishing from "Desert" Tactical Boots

It is critical not to confuse a classic desert boot with a modern military or tactical "desert" boot.

Tactical boots are built for performance in harsh, arid environments. They use rugged materials like full-grain leather, water-resistant Cordura nylon, and waterproof-breathable membranes like GORE-TEX. Their purpose is protection and durability, not casual comfort.

Understanding the Trade-offs

The classic materials that give the desert boot its character also come with inherent limitations.

Suede's Vulnerability

Traditional suede is not waterproof and is susceptible to staining. It requires more care and is less suited for wet or muddy conditions compared to the full-grain leather used on duty boots.

The Crepe Sole's Lifespan

While exceptionally comfortable, crepe soles can wear down more quickly than harder synthetic soles. They also tend to darken as they pick up dirt and can become sticky in very high temperatures.

Limited All-Terrain Traction

The soft, relatively flat crepe sole provides excellent comfort on pavement and hard surfaces but lacks the aggressive tread and rigidity needed for serious hiking or slippery conditions.

Making the Right Choice for Your Goal

Understanding these materials allows you to select a boot that aligns perfectly with your needs.

- If your primary focus is classic style and casual comfort: Stick with the traditional suede upper and crepe sole for its authentic look and unparalleled flexibility.

- If your primary focus is versatility and easier maintenance: Consider a variation with a smooth leather upper and a more durable synthetic rubber sole.

- If your primary focus is performance in harsh outdoor conditions: A true tactical boot, with materials like nylon and waterproof membranes, is the correct and necessary choice.

Ultimately, choosing the right boot comes from understanding that its materials are its mission statement.

Summary Table:

| Component | Classic Material | Modern Alternative | Key Characteristic |

|---|---|---|---|

| Upper | Suede / Soft Leather | Smooth Leather, Canvas | Breathable, soft, flexible |

| Sole | Natural Crepe Rubber | Polyurethane / Synthetic Rubber | Cushioned, flexible, quiet |

| Construction | Stitch-Down | - | Simple, flexible, clean look |

Need high-quality desert boots for your brand or store?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We expertly craft authentic desert boots using premium suede and crepe rubber, alongside modern variations with durable synthetic soles to meet any market demand. Our production capabilities encompass all types of shoes and boots, ensuring you get the perfect product for your customers.

Contact our team today to discuss your production needs and get a quote!

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- Can Chukka boots be worn in different seasons? Your Guide to Year-Round Style

- What are the most popular shoe choices for business casual? Loafer, Oxford, or Dress Boot?

- Where did the Chukka boot originate? From Polo Fields to Modern Wardrobe

- What are the features of Chukka boots and how can they be styled? Master Versatile Ankle-High Style

- How often should business casual shoes be rotated? Maximize Longevity with Proper Care

- What are loafers, and how are they used in casual wear? Elevate Your Style with Effortless Sophistication

- Are casual dress shoes more comfortable than traditional? The Truth About All-Day Wear

- Can you describe a casual outfit featuring chukka boots? Master Versatile Style with the Perfect Pair