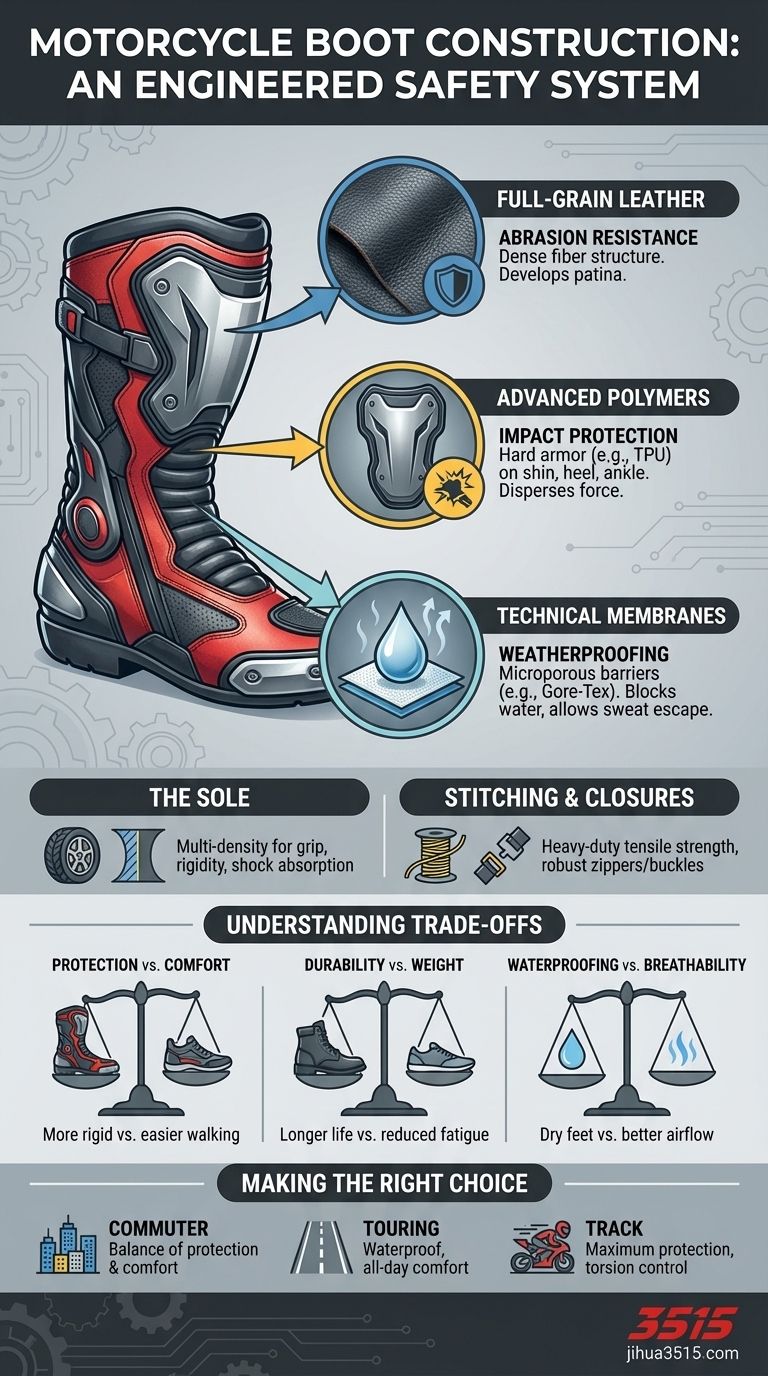

At their core, modern motorcycle boots are engineered systems constructed from three primary material categories: high-quality leathers for abrasion resistance, advanced polymers for impact protection, and technical membranes for weatherproofing. These materials are rarely used in isolation; instead, they are strategically combined to create footwear that balances safety, comfort, and durability for a specific riding purpose.

The key insight is that a motorcycle boot isn't just made of one material. It's a composite structure where each component—from the full-grain leather chassis to the polymer armor and multi-density sole—is chosen to solve a specific safety or comfort problem a rider faces.

The Core Trio of Motorcycle Boot Materials

Understanding the primary materials is the first step to decoding a boot's intended purpose and performance capabilities. Each one serves a distinct, critical function in protecting the rider.

Leather: The Foundation of Abrasion Resistance

The most traditional and trusted material is full-grain leather. Its dense fiber structure provides exceptional resistance to abrasion, which is critical for protecting your skin if you slide during a crash.

Unlike lesser grades, full-grain leather maintains its original surface, making it incredibly durable and capable of developing a unique patina over time. It is the gold standard for the main chassis of many touring, cruiser, and racing boots.

Advanced Polymers: The Shield for Impact Protection

Where leather excels at sliding, hard polymers excel at absorbing direct impacts. These are the plastics and composites you see on the exterior of many boots.

This impact-resistant armor is strategically placed over vulnerable areas like the shin, heel, and ankle. Materials like Thermoplastic Polyurethane (TPU) are engineered to be rigid and disperse the force of an impact away from your bones and joints.

Technical Fabrics & Membranes: The Barrier Against the Elements

Modern boots often incorporate advanced synthetic fabrics and waterproof membranes. The most well-known is Gore-Tex, a microporous membrane that blocks water from entering while allowing sweat vapor to escape.

These materials are essential for comfort on long rides or in unpredictable weather. They ensure your feet stay dry from both rain and perspiration, preventing discomfort and distraction.

Beyond the Chassis: Critical Supporting Components

The main materials form the boot's core, but its overall performance depends equally on the components that hold it together and connect you to the motorcycle.

The Sole: Your Connection to the Road and Bike

The sole is far more than a simple piece of rubber. High-quality boots use dual or triple-density soles to achieve multiple goals at once.

A softer compound might be used for grip on the footpegs and pavement, while a much stiffer compound provides rigidity to prevent the foot from flexing unnaturally during an impact. This design also incorporates shock-absorbing qualities for comfort when walking.

Stitching and Closures: The System's Unsung Heroes

The quality of a boot's construction is often revealed in its stitching. Heavy-duty, high-tensile stitching is crucial for holding the leather and armor panels together under the extreme forces of a crash.

Similarly, closure systems—whether zippers, buckles, or hook-and-loop fasteners—must be robust. They ensure the boot stays securely on your foot when it matters most, keeping the integrated armor in the correct position.

Understanding the Trade-offs

No single boot is perfect for every situation. Choosing the right material composition involves balancing competing priorities.

Protection vs. Comfort

Generally, the more protective a boot is—with extensive polymer armor and a rigid structure—the less comfortable it will be for walking. Race boots offer maximum safety on the track but are stiff and awkward for walking around town.

Durability vs. Weight

Full-grain leather is exceptionally durable but can be heavy. Boots that use more synthetic textiles and lighter-weight polymers can reduce fatigue on long rides but may not offer the same multi-decade lifespan as a well-maintained leather boot.

Waterproofing vs. Breathability

A fully waterproof boot with a membrane like Gore-Tex is excellent for touring in varied climates. However, in consistently hot and dry conditions, that same membrane can limit airflow, making a non-waterproof, more breathable boot a more comfortable choice.

Making the Right Choice for Your Goal

Your ideal boot depends entirely on your primary riding style. Match the boot's material system to your specific needs.

- If your primary focus is daily commuting or casual riding: Seek a balance of leather for abrasion resistance, subtle ankle armor, and a comfortable, flexible sole.

- If your primary focus is long-distance touring: Prioritize a proven waterproof membrane like Gore-Tex, all-day comfort, and robust construction with good sole support.

- If your primary focus is track days or aggressive canyon riding: Demand maximum protection with extensive external polymer armor, a torsion-control system, and superior abrasion resistance.

Ultimately, choosing the right boot means understanding that you are investing in an engineered safety system designed for your specific purpose on the road.

Summary Table:

| Material Category | Primary Function | Common Use Cases |

|---|---|---|

| Full-Grain Leather | Abrasion Resistance | Touring, Cruiser, Racing Boots |

| Advanced Polymers (e.g., TPU) | Impact Protection | Ankle, Shin, and Heel Armor |

| Technical Membranes (e.g., Gore-Tex) | Weatherproofing & Breathability | Touring and Adventure Boots |

Ready to manufacture high-performance motorcycle boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring the precise material combinations and construction quality your customers demand.

Contact our expert team today to discuss your specific manufacturing needs and bring your vision to life.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What is the role of high-precision wearable motion sensors in footwear testing? Establish Real-World Baseline Speed

- How are the toebox and heel padding damage evaluated? A 1-5 Scale Guide to Shoe Condition

- How does the uniform provision of standardized PPE impact safety management? Elevate Construction Site Security

- What technical advantages do commercial 3D foot scanners offer? Experience Digital Precision in Footwear Manufacturing

- What are the advantages and disadvantages of Birko-Flor? A Practical Guide to Choosing Your Footwear Material

- What performance improvements do conjugated materials offer for lightweight outsoles? Unlock Next-Gen Footwear Efficiency

- What role does high-precision 3D modeling software play in R&D? Digital Innovation in Footwear Engineering

- Why do purpose-built motorcycle boots cost more than fashion boots? Invest in Critical Safety Features