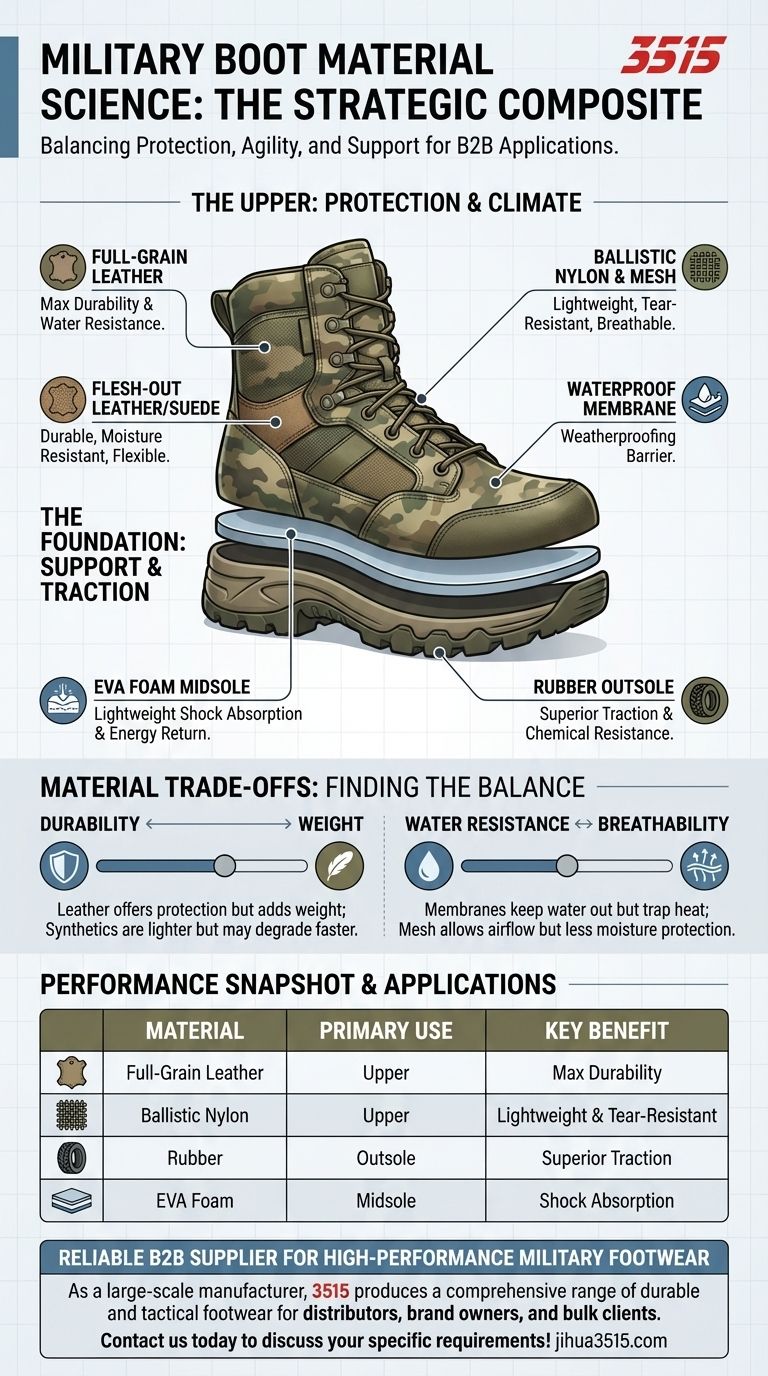

Military camouflage boots rely on a strategic combination of robust natural and engineered materials. The most common construction pairs full-grain or flesh-out leather for structural durability with ballistic nylon for breathability and weight reduction. These uppers are typically grounded on high-traction rubber outsoles and shock-absorbing EVA foam midsoles.

The ideal military boot is rarely made of a single material; it is a composite system. The engineering goal is to balance the heavy-duty protection of leather with the lightweight, ventilating properties of synthetic textiles.

Anatomy of the Upper: Protection vs. Agility

The upper part of the boot dictates its longevity and climate suitability. Manufacturers mix materials here to optimize for specific environments.

The Role of Leather

Full-grain leather remains the standard for maximum durability. It offers excellent natural water resistance and protects the foot against abrasion in rugged terrain.

Flesh-out cattlehide leather is frequently used in modern military specifications. Unlike standard leather, this material is highly durable and specifically resistant to moisture, making it ideal for harsh conditions.

Suede offers a softer, more flexible alternative. It provides immediate comfort and reduced weight, though it is more susceptible to staining than full-grain options.

Engineered Synthetics and Nylon

To reduce the overall weight of the boot, leather is almost always paired with nylon. Standard nylon panels provide essential breathability, preventing overheating during high activity.

Ballistic nylon is a specialized variant often used in high-stress areas. It is designed to be highly resistant to tearing and abrasions while remaining lighter than leather.

Mesh panels are integrated into boots designed for hot climates. These engineered textiles maximize airflow to keep feet cool and dry.

Weatherproofing Barriers

For wet environments, boots may incorporate waterproof membranes or neoprene. These synthetic layers create an impenetrable barrier to water while attempting to manage internal moisture.

The Foundation: Soles and Support Systems

The materials underfoot are just as critical as those surrounding the ankle. They manage energy return and stability.

Outsole Traction

Rubber is the universal standard for the outsole. It provides the necessary friction for traction on loose dirt, mud, and pavement, and it is chemically resistant to oils.

Midsole Cushioning

Between the foot and the ground lies the midsole, typically constructed from EVA (Ethylene Vinyl Acetate) foam. This material is lightweight and compresses to absorb shock, reducing fatigue during long marches.

Understanding the Trade-offs

Selecting the right boot requires understanding that material benefits often come at a cost. There is no single material that excels in every category.

Durability vs. Weight

Full-grain leather offers the highest protection but significantly increases the weight of the boot. Conversely, boots heavy in synthetic leather or lightweight nylon offer agility but may degrade faster under heavy abrasion.

Water Resistance vs. Breathability

Materials like full-grain leather and neoprene membranes excel at keeping water out. However, they can trap heat and sweat inside.

Mesh and standard nylon allow heat to escape effectively. The downside is that they offer little protection against external moisture intrusion compared to solid leather.

Maintenance Requirements

Flesh-out leather and suede require specific care to maintain their appearance and structure. Synthetic materials are generally lower maintenance but are harder to repair if they tear or crack.

Making the Right Choice for Your Goal

The "best" material composition depends entirely on your operational environment.

- If your primary focus is Durability and Water Resistance: Prioritize boots with high full-grain leather content and minimal mesh panels.

- If your primary focus is Speed and Hot Climates: Look for boots maximizing ballistic nylon and mesh vents to reduce weight and heat.

- If your primary focus is Shock Absorption: Ensure the boot utilizes a substantial EVA foam midsole rather than a solid rubber construction.

Your footwear materials dictate your endurance; choose the composition that solves your environmental challenges.

Summary Table:

| Material | Primary Use | Key Benefit |

|---|---|---|

| Full-Grain Leather | Upper | Maximum Durability & Water Resistance |

| Ballistic Nylon | Upper | Lightweight & Tear-Resistant |

| Rubber | Outsole | Superior Traction & Chemical Resistance |

| EVA Foam | Midsole | Lightweight Shock Absorption |

| Waterproof Membrane | Lining | Weatherproofing for Wet Environments |

Need a reliable supplier for high-performance military boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and tactical footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of military boots, ensuring the perfect balance of protection, agility, and comfort for any environment.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

People Also Ask

- Can combat boots be worn with a suit? A Guide to High-Risk, High-Reward Style

- What issues did the U.S. military identify with leather combat boots in tropical climates? A Lesson in Material Failure

- What distinguishes Marine Corps boots? The Definitive Guide to USMC-Spec Footwear

- What are the primary uses of jump boots? Rigid Ankle Support for High-Impact Landings

- How did classic combat boots compare to everyday boots in the early 20th century? Discover the Shared History of Durable Footwear.

- What are some real-world experiences of hikers using military boots? Discover the pros and cons for your next trek.

- What are the best practices for drying and storing military boots? Extend Their Lifespan & Readiness

- What protective elements are found in military boots? Built for Durability & Safety in Harsh Conditions