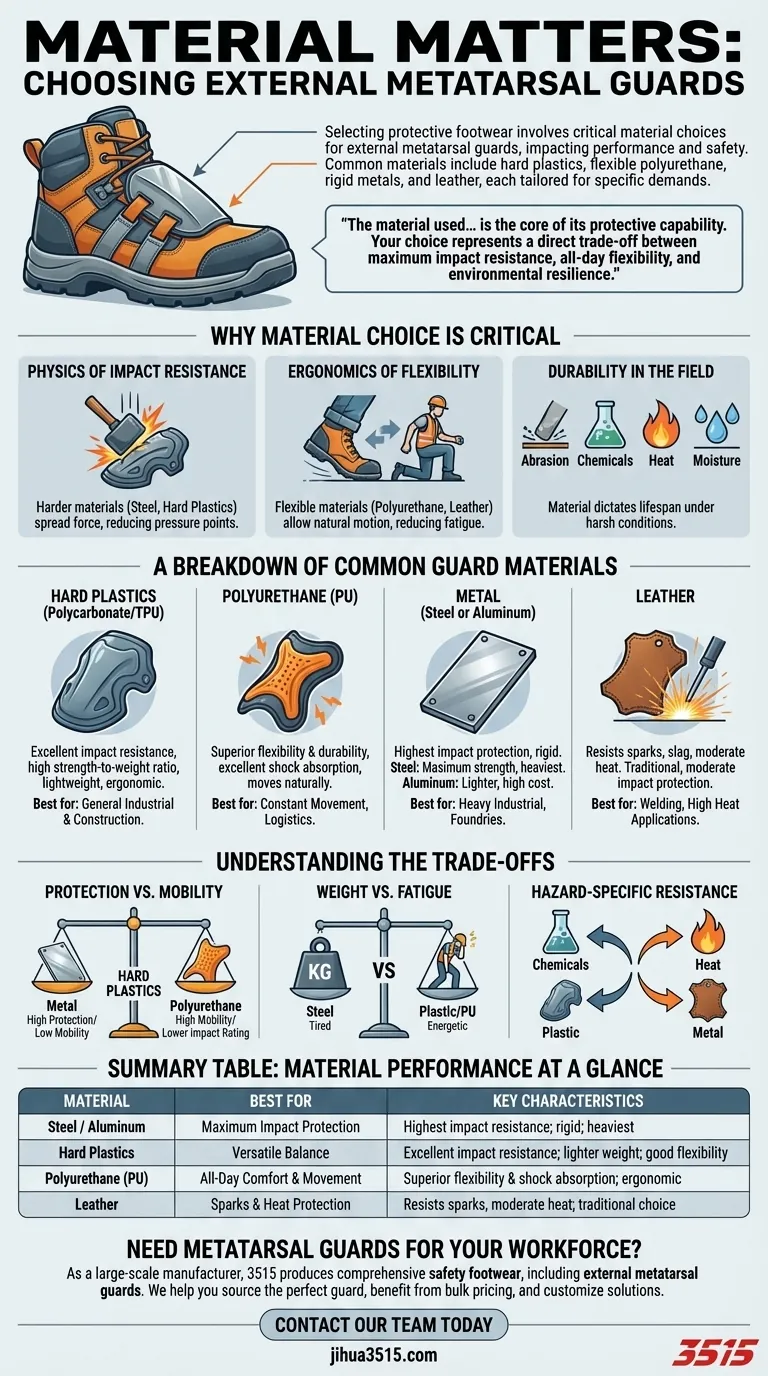

When selecting protective footwear, the material of an external metatarsal guard is a critical factor in its performance. These guards are most commonly constructed from hard plastics like polycarbonate, flexible polyurethane, rigid metals such as steel or aluminum, and traditional leather. Each material is chosen to meet specific safety demands and environmental conditions.

The material used in an external metatarsal guard is not just a detail—it is the core of its protective capability. Your choice represents a direct trade-off between maximum impact resistance, all-day flexibility, and environmental resilience.

Why Material Choice is Critical

The primary function of a metatarsal guard is to dissipate the force of an impact across the top of the foot, preventing crushing injuries. The material used determines how effectively it can perform this function while remaining practical for daily wear.

The Physics of Impact Resistance

A metatarsal guard's first job is to absorb and deflect energy from a falling or rolling object. Harder, more rigid materials are inherently better at this.

Materials like steel and hard plastics spread the force over a wider surface area, significantly reducing the pressure on any single point of your foot.

The Ergonomics of Flexibility

While protection is paramount, a guard must not excessively hinder movement. A worker needs to be able to walk, kneel, and pivot comfortably throughout a shift.

More flexible materials like polyurethane and, to some extent, leather, allow for a more natural range of motion, reducing fatigue and improving overall comfort and compliance.

Durability in the Field

The work environment exposes safety equipment to abrasion, chemicals, extreme temperatures, and moisture. The guard's material dictates its lifespan and reliability under these conditions.

A Breakdown of Common Guard Materials

Each material offers a distinct profile of protection, weight, and flexibility, making it suitable for different applications and hazard levels.

Hard Plastics (Polycarbonate/TPU)

Hard plastics, particularly polycarbonate and thermoplastic urethane (TPU), represent a modern, balanced solution. They offer a very high strength-to-weight ratio.

These materials provide excellent impact resistance, are significantly lighter than metal, and can be molded into ergonomic shapes. They are the most common choice for general-purpose industrial and construction work.

Polyurethane (PU)

Polyurethane is prized for its unique combination of durability and flexibility. It excels at shock absorption rather than just rigid deflection.

This material is ideal for roles that require constant movement, as it moves with the foot more naturally. It offers reliable protection for moderate impact risks without the stiffness of hard plastics or metal.

Metal (Steel or Aluminum)

Metal guards offer the highest level of impact protection available. They are the standard for heavy industrial environments where the risk of severe crushing injuries is high.

Steel provides maximum strength but is the heaviest option. Aluminum offers a lighter alternative while still providing exceptional impact resistance, though often at a higher cost.

Leather

Leather is a traditional material used primarily for its ability to resist sparks, slag, and moderate heat. It is a common choice in welding and foundry applications.

While it offers some impact protection, leather is not designed for the same level of heavy impact as metal or hard plastics. Its primary advantage is protection against specific thermal hazards.

Understanding the Trade-offs

Choosing the right metatarsal guard requires an honest assessment of your work environment's specific risks and physical demands.

Protection vs. Mobility

This is the central compromise. Metal guards offer unparalleled protection but are rigid and can restrict movement. Polyurethane guards provide maximum mobility but may not be rated for the highest impact levels. Hard plastics sit in the middle, offering a balance of both.

Weight vs. Fatigue

The weight of a guard directly impacts worker fatigue over an 8- to 12-hour shift. A heavy steel guard, while protective, can be more tiring than a lightweight plastic or polyurethane alternative. This is a critical factor for jobs that involve extensive walking or climbing.

Hazard-Specific Resistance

A standard plastic guard may be ideal for a warehouse but could degrade quickly when exposed to certain chemicals or melt in a high-heat environment where leather or metal would be required. The material must match the total environmental risk profile.

Making the Right Choice for Your Goal

Your specific job hazards should be the primary guide in your material selection.

- If your primary focus is maximum impact protection: Choose guards made from steel or aluminum for environments with high risks from heavy falling objects, such as in foundries or heavy manufacturing.

- If your primary focus is a versatile balance of protection and flexibility: Look for guards made from hard plastics like polycarbonate or TPU, which offer an excellent all-around solution for construction and general industry.

- If your primary focus is all-day comfort and constant movement: Consider polyurethane guards, which provide reliable shock absorption and ergonomics for logistics, transportation, or trade work.

- If your primary focus is protection from sparks and high heat: Leather guards are the proven and effective choice for welding or working with molten materials.

Understanding the properties of each material transforms a simple piece of equipment into a precisely chosen tool for your personal safety.

Summary Table:

| Material | Best For | Key Characteristics |

|---|---|---|

| Steel / Aluminum | Maximum Impact Protection | Highest level of impact resistance; rigid; heavier weight |

| Hard Plastics (Polycarbonate/TPU) | Versatile Balance | Excellent impact resistance; lighter weight; good flexibility |

| Polyurethane (PU) | All-Day Comfort & Movement | Superior flexibility and shock absorption; ergonomic |

| Leather | Sparks & Heat Protection | Resists sparks and moderate heat; traditional choice for welding |

Need Metatarsal Guards for Your Workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear, including external metatarsal guards, for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the right protection for your specific hazards.

We can help you:

- Source the perfect guard based on your unique impact, flexibility, and environmental needs.

- Benefit from bulk pricing and reliable supply chain for large orders.

- Customize solutions for your brand or workforce.

Let's discuss your requirements → Contact Our Team Today

Visual Guide

Related Products

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What are the different names for safety shoes? Choose the Right Protection for Your Job

- What are the common types of safety boots based on their protective features? Select the Right Boot for Your Job Hazard

- Why is metatarsal protection required on job sites? Essential Safety for Heavy-Duty Work

- What are the differences between internal and external metatarsal guards? Choose the Right Protection for Your Job

- Why are metatarsal boots important in high-impact workplaces? Essential Protection for Heavy Industry