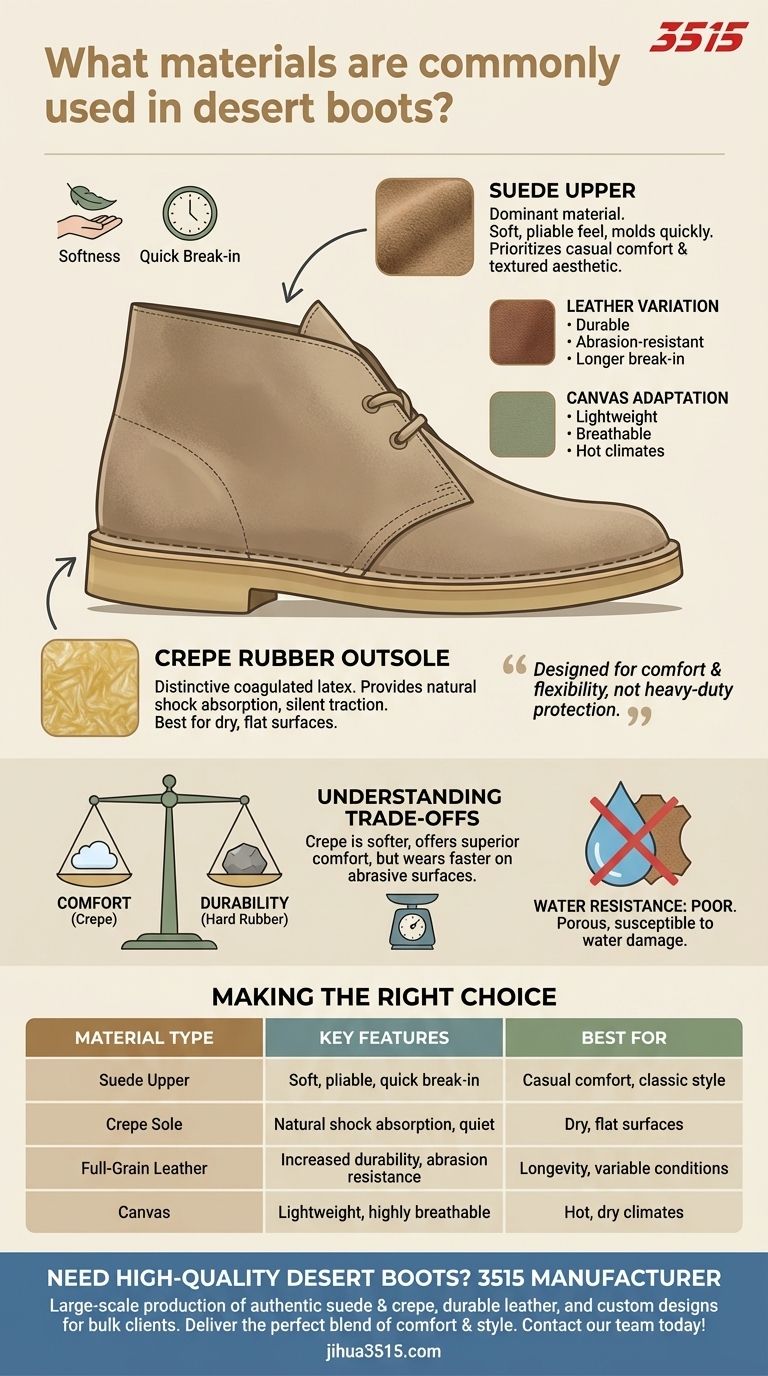

The quintessential desert boot is defined by a specific combination of materials: a suede upper paired with a crepe rubber outsole. While modern adaptations may utilize full-grain leather, canvas, or synthetic textiles, the traditional suede-and-crepe configuration remains the standard for this category of footwear.

The classic desert boot is designed for comfort and flexibility rather than heavy-duty protection. Its core identity relies on the interplay between the soft, pliable suede upper and the cushioned, shock-absorbing nature of the crepe sole.

Anatomy of the Upper

The material chosen for the upper determines the boot's breathability, break-in period, and aesthetic character.

The Dominance of Suede

Suede is the most frequently used material for desert boot uppers.

It provides a softer, more pliable feel compared to full-grain leather, allowing the boot to mold to the foot quickly.

This material choice prioritizes casual comfort and a textured aesthetic over water resistance.

Leather and Canvas Variations

While less common than suede, full-grain leather is sometimes used for increased durability.

Leather versions offer better resistance to abrasion than suede but typically require a longer break-in period.

Canvas adaptations are also available, offering a lightweight and highly breathable alternative ideal for hot, dry climates.

The Foundation: The Crepe Sole

The outsole is the most distinct technical feature of a true desert boot.

Composition of Crepe

The traditional outsole is made from crepe rubber, a form of coagulated latex.

References describe this material as a soft rubber or resin, known for its distinctive crinkled texture.

Performance Characteristics

Crepe rubber is chosen specifically for comfort and silent traction.

Unlike hard vulcanized rubber, crepe provides natural shock absorption, making it suitable for long periods of walking on dry, flat surfaces.

Understanding the Trade-offs

When selecting desert boots, it is vital to understand the limitations inherent in these materials compared to other boot categories.

Water Resistance

Standard desert boot materials—suede and crepe—are not naturally waterproof.

Unlike rain boots made from rubber or neoprene, or waterproof boots utilizing membranes, suede is porous and susceptible to water damage.

Durability vs. Comfort

The crepe sole is softer than the thermoplastic rubber (TPR) found in walking boots or the rigid outsoles of tactical boots.

While this offers superior comfort, crepe wears down faster on abrasive concrete or asphalt than harder rubber compounds.

Making the Right Choice for Your Goal

The materials used in a desert boot dictate its best use case. Before purchasing, consider your primary environment.

- If your primary focus is immediate comfort and style: Prioritize suede uppers with genuine crepe soles for maximum flexibility and a classic look that requires zero break-in time.

- If your primary focus is longevity in variable weather: Consider full-grain leather variants or adaptations with synthetic soles, as traditional crepe and suede perform poorly in wet conditions.

Select the material that aligns with your environment, accepting that the desert boot is a specialist in dry comfort, not a generalist in all-weather protection.

Summary Table:

| Material Type | Key Features | Best For |

|---|---|---|

| Suede Upper | Soft, pliable, quick break-in | Casual comfort, classic style |

| Crepe Sole | Natural shock absorption, quiet traction | Dry, flat surfaces |

| Full-Grain Leather | Increased durability, abrasion resistance | Longevity, variable conditions |

| Canvas | Lightweight, highly breathable | Hot, dry climates |

Need high-quality desert boots for your customers? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear, including authentic suede and crepe desert boots, durable leather variants, and custom designs for distributors, brand owners, and bulk clients. Let us help you deliver the perfect blend of comfort and style. Contact our team today to discuss your production needs!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- High Performance Fire-Retardant Waterproof Safety Boots

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

People Also Ask

- What cultural impact has the Desert Boot had? A Design Icon That Shaped Generations

- What materials and colors are available for chukka boots? Find Your Perfect Style & Fit

- How should business casual shoes be maintained? A Proactive System for Longevity & Style

- What is the connection between Chukka boots and World War II? Discover the History of the Iconic Desert Boot

- Can Chukka boots be worn with a suit? The Definitive Guide to a Stylish Pairing

- Are chukka boots considered formal or casual? Master Their Versatility for Any Outfit

- What are some classic shoe styles recommended for business casual attire? Elevate Your Professional Wardrobe

- What features ensure the longevity of chukka boots? Invest in Quality Construction & Materials