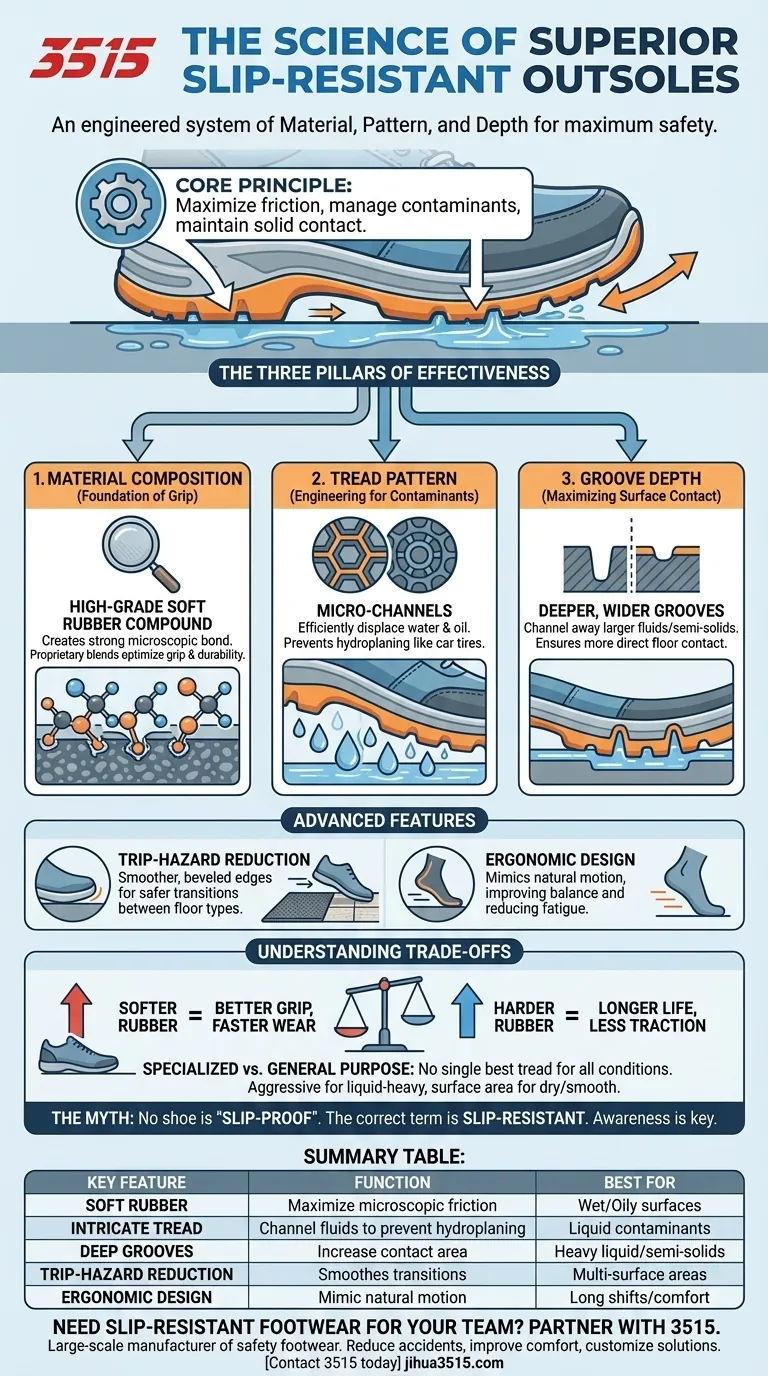

The effectiveness of a slip-resistant outsole is not the result of a single feature, but a carefully engineered system. It comes from the interplay of three critical elements: the specific material used for the sole, the geometric design of its tread pattern, and the depth of its grooves. Together, these components work to maximize friction and actively manage contaminants like water or oil.

The core principle behind a superior slip-resistant shoe is not just about gripping a dry floor. It's about how the outsole is engineered to cut through liquid contaminants, channel them away, and maintain direct, solid contact with the surface underneath.

The Three Pillars of Outsole Effectiveness

True slip resistance is built on a foundation of material science and fluid dynamics. Each component of the outsole is designed to solve a specific problem encountered on hazardous surfaces.

Material Composition: The Foundation of Grip

The type of material used is the starting point for all traction.

Most high-performance outsoles use a high-grade, soft rubber compound. This material naturally has a high coefficient of friction, allowing it to create a strong bond with the floor surface on a microscopic level.

However, not all rubber is created equal. The specific blend is often a proprietary secret, optimized for grip without sacrificing too much durability.

Tread Pattern: Engineering for Contaminants

The visible pattern on the bottom of the shoe is its most active safety feature.

These patterns, often featuring intricate hexagonal or circular shapes, are not for aesthetics. They are designed as micro-channels that efficiently displace water and other liquids from beneath the shoe.

Think of it like the treads on a car tire. By pushing fluid out to the sides, the pattern prevents a layer of liquid from forming between the sole and the floor, a phenomenon known as hydroplaning, which is a primary cause of slips.

Groove Depth: Maximizing Surface Contact

The depth of the channels in the tread pattern plays a crucial role.

Deeper and wider grooves are more effective at channeling away larger amounts of fluid and even some semi-solid contaminants. This ensures more of the outsole's surface area makes direct contact with the floor.

This increased contact area directly translates to greater friction and a more secure footing, especially when moving quickly or changing direction.

Beyond Grip: Advanced Outsole Design Features

The most advanced designs consider the entire dynamic of walking and working, incorporating features that enhance overall safety and stability.

Trip-Hazard Reduction

Some outsoles feature reduced trip-hazard zones. These are typically smoother, beveled areas around the edge of the sole.

This design allows for easier and safer movement when transitioning between different flooring types, such as from a mat to a tile floor, reducing the chance of the shoe's edge catching and causing a stumble.

Ergonomic Design for Stability

Certain patterns are designed to mimic the foot's natural motion.

While this provides enhanced comfort, it also contributes to safety. A more natural stride improves balance and stability, reducing the fatigue that can lead to missteps and accidents over a long shift.

Understanding the Trade-offs

No single shoe is perfect for every situation. Understanding the inherent trade-offs is key to choosing the right tool for the job.

The Durability vs. Softness Dilemma

There is a direct trade-off between the softness of the rubber and its lifespan.

A softer rubber compound provides exceptional grip, especially on smooth, wet surfaces, but it will wear down more quickly. A harder, more durable compound will last longer but may offer less traction in demanding conditions.

Specialized vs. General-Purpose Treads

A tread pattern optimized for displacing water in a commercial kitchen may be less effective on a dusty warehouse floor.

Aggressive, deep-channeled treads are ideal for liquid-heavy environments. In contrast, a pattern with more surface area might be better for dry, smooth surfaces. There is no single "best" tread for all conditions.

The Myth of "Slip-Proof"

It is crucial to understand that no shoe is truly "slip-proof." The correct term is slip-resistant.

These shoes are engineered to significantly reduce the risk of slips in specific environments. However, they do not eliminate the risk entirely. Awareness and caution remain essential safety components.

Making the Right Choice for Your Environment

Your specific workplace environment dictates which outsole features are most critical for your safety.

- If your primary focus is wet or oily surfaces (e.g., kitchens, food processing): Prioritize shoes with a soft rubber compound and an intricate tread pattern with deep micro-channels designed for maximum fluid displacement.

- If your primary focus is moving between different surfaces (e.g., healthcare, logistics): Look for versatile designs that include trip-hazard reduction zones and a tread that balances grip with smooth transitions.

- If your primary focus is all-day stability on varied terrain (e.g., tactical, field work): Seek out durable rubber outsoles with specialized, multi-directional tread patterns designed to provide control on unpredictable surfaces.

By understanding how these elements work together, you can look beyond simple marketing claims and select a shoe that is truly engineered for your safety.

Summary Table:

| Key Feature | Function | Best For |

|---|---|---|

| Soft Rubber Compound | Maximizes microscopic friction with the floor. | Wet, oily surfaces like kitchens. |

| Intricate Tread Pattern | Channels fluids away to prevent hydroplaning. | Areas with liquid contaminants. |

| Deep Grooves | Increases surface contact by displacing more fluid. | Heavy liquid or semi-solid spills. |

| Trip-Hazard Reduction | Smoothes transitions between surfaces. | Logistics, healthcare, multi-surface areas. |

| Ergonomic Design | Mimics natural foot motion for stability. | Long shifts requiring all-day comfort and balance. |

Need Slip-Resistant Footwear for Your Team? Partner with 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, engineered with the precise material compounds and tread patterns your workforce needs.

We help you:

- Reduce workplace accidents with scientifically designed outsoles.

- Improve employee comfort and productivity with ergonomic stability features.

- Customize solutions for specific environments, from kitchens to warehouses.

Contact 3515 today to discuss your safety footwear requirements and receive a tailored solution from an industry leader.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.