Choosing the right oilfield boot is a critical decision that directly impacts your safety and performance. The key features to consider are a specific combination of mandated safety compliance, durable construction, and all-day comfort. This includes ASTM-rated toe protection, metatarsal guards, puncture resistance, exceptional slip-resistance for slick surfaces, and electrical hazard ratings appropriate for your specific environment.

Your choice isn't just about footwear; it's about selecting a critical piece of personal protective equipment (PPE). The best boot balances the mandatory safety features required for your site with the durability and comfort needed to prevent injury and reduce fatigue over long shifts.

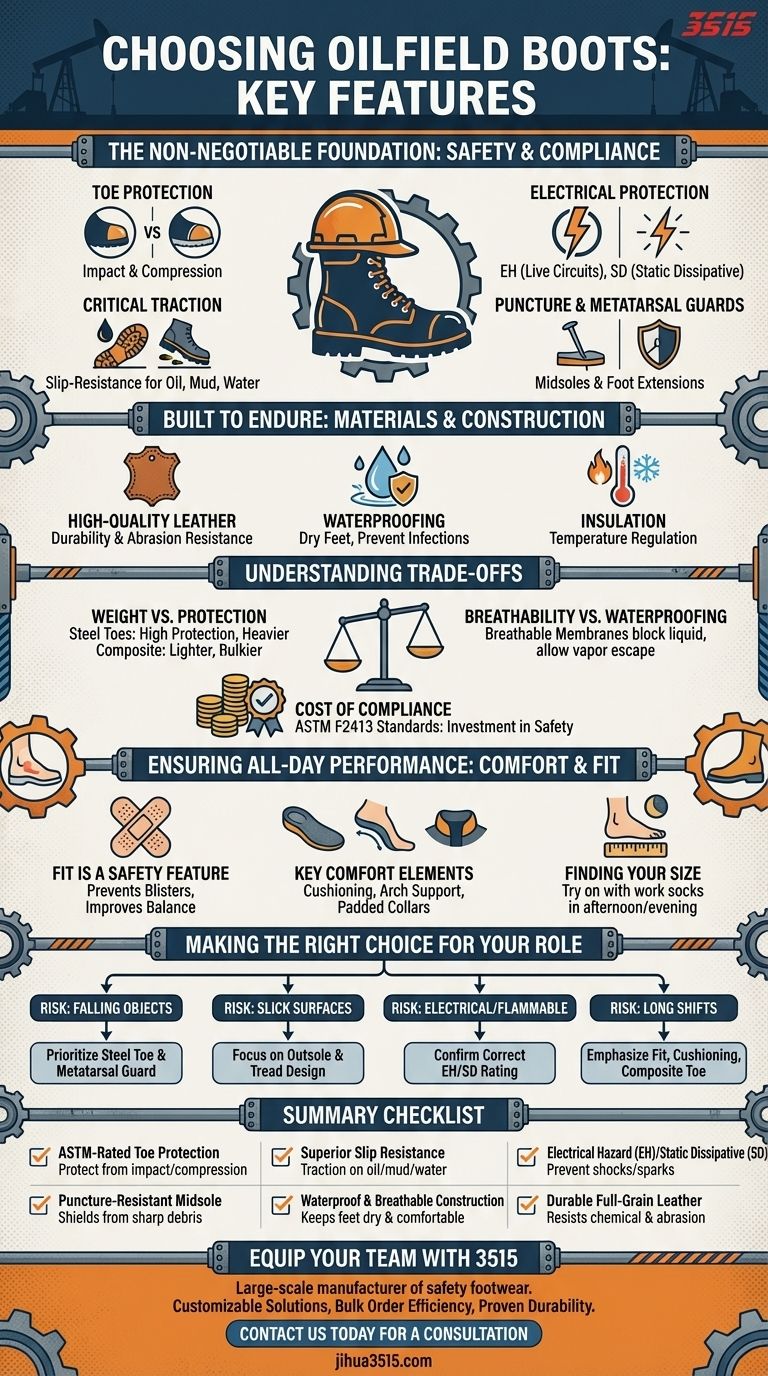

The Non-Negotiable Foundation: Safety & Compliance

Your boot is your first line of defense against the unique hazards of an oilfield. Understanding the specific safety ratings is not optional—it's essential for protecting yourself from serious injury.

Understanding Toe Protection (Steel vs. Composite)

The most fundamental safety feature is the reinforced toe cap, which protects against impact and compression from heavy equipment and falling objects.

You will primarily choose between steel toes, which offer maximum protection and are the traditional standard, and composite toes (made of carbon fiber, plastic, or Kevlar), which are lighter and do not conduct electricity or temperature.

Critical Traction and Slip Resistance

Oil, mud, and water create constant slip-and-fall hazards. An effective oilfield boot must have an outsole designed for superior traction on these surfaces.

Look for boots with deep lugs and a clearly defined heel for muddy or uneven terrain. Materials like high-grade rubber and polyurethane offer excellent durability and grip.

Specialized Electrical Protection (EH vs. SD)

Depending on your role, you may need specific electrical protection. These features are not interchangeable.

An Electrical Hazard (EH) rating means the boot is insulated to protect you from stepping on live electrical circuits. A Static Dissipative (SD) rating prevents the buildup of static electricity, which is critical for preventing sparks in flammable environments.

Beyond the Toe: Puncture and Metatarsal Guards

Many oilfield injuries aren't to the toes. Puncture-resistant midsoles protect the bottom of your foot from nails, scrap metal, and other sharp debris.

Metatarsal guards are extensions that cover the top of your foot (the metatarsal bones), shielding them from falling tools or heavy objects that could cause crushing injuries.

Built to Endure: Materials and Construction

The harsh conditions of an oilfield will quickly destroy inferior boots. Durability is a function of both the materials used and how the boot is constructed.

The Role of High-Quality Leather

Full-grain leather is the preferred upper material for its exceptional durability, breathability, and resistance to wear and tear. It provides a strong barrier against chemicals and abrasion.

The Importance of Waterproofing

Working in wet conditions is common. A waterproof membrane is essential not just for comfort, but for preventing blisters, fungal infections, and foot fatigue caused by prolonged dampness.

Insulation for Temperature Extremes

Your work environment can expose you to extreme heat or cold. Insulated boots are crucial for maintaining a safe and stable foot temperature, preventing frostbite in the cold and reducing heat stress from hot surfaces.

Understanding the Trade-offs

No single boot is perfect for every situation. Choosing the right one involves balancing competing priorities.

Weight vs. Maximum Protection

Steel toe boots typically offer the highest safety ratings but are also the heaviest, which can contribute to fatigue. Composite toes are significantly lighter but can sometimes be bulkier to achieve the same safety rating as steel.

Breathability vs. Waterproofing

A completely sealed, waterproof boot can trap sweat, leading to discomfort. High-quality boots solve this by using breathable waterproof membranes that allow moisture vapor to escape while blocking liquid water from entering.

The Cost of Compliance

Boots that meet or exceed rigorous safety standards like ASTM F2413 require advanced materials, complex construction, and extensive testing. While they cost more, this is an investment in your personal safety and compliance, not an optional expense.

Ensuring All-Day Performance: Comfort and Fit

A safe boot that is too uncomfortable to wear properly is not a safe boot at all. Comfort and fit are integral to both safety and productivity.

Why Fit is a Safety Feature

A poorly fitting boot can cause painful blisters and chafing, which can be distracting and dangerous on a hazardous job site. More importantly, improper fit can affect your balance and lead to slips, trips, and falls.

Key Comfort Elements

Look for features that reduce the strain of being on your feet for 12-hour shifts. This includes heavily cushioned insoles, proper arch support, and padded collars that prevent ankle chafing.

The Right Way to Find Your Size

Always try on boots in the afternoon or evening when your feet have naturally swelled to their largest size. Wear the same thick socks you use for work to get an accurate sense of the fit. If you are between sizes, consider a wider width if available.

Making the Right Choice for Your Role

Select your boots based on the most significant hazards you face daily.

- If your primary risk is falling objects and heavy equipment: Prioritize boots with the highest-rated steel toe protection and a metatarsal guard.

- If you work on slick, uneven, or muddy surfaces: Focus on the outsole design, ensuring it's rated for high slip-resistance with a tread pattern suited for your environment.

- If you work near live electrical circuits or in flammable environments: Confirm your boots have the correct EH (Electrical Hazard) or SD (Static Dissipative) rating required by your site.

- If you work long shifts and cover a lot of ground: Do not compromise on fit; look for cushioned insoles, good arch support, and consider a lighter composite toe if safety standards permit.

Ultimately, the best oilfield boot is the one that meets the specific safety demands of your job without compromising the support you need to do it well.

Summary Table:

| Key Feature | Why It Matters |

|---|---|

| ASTM-Rated Toe Protection | Protects against impact and compression from heavy objects. |

| Superior Slip Resistance | Essential for traction on oil, mud, and water-covered surfaces. |

| Electrical Hazard (EH) / Static Dissipative (SD) Rating | Prevents electrical shocks or sparks in flammable environments. |

| Puncture-Resistant Midsole | Shields feet from sharp debris like nails and metal. |

| Waterproof & Breathable Construction | Keeps feet dry and comfortable, preventing blisters and fatigue. |

| Durable Full-Grain Leather | Provides a strong barrier against chemicals, abrasion, and wear. |

Ready to Equip Your Team with the Right Oilfield Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, engineered to meet the highest standards of protection, durability, and comfort for demanding environments.

We provide:

- Customizable Solutions: Tailored boots to meet your specific job site hazards and compliance requirements (ASTM, EH, SD).

- Bulk Order Efficiency: Streamlined logistics and competitive pricing for large-scale procurement.

- Proven Durability: Boots built with premium materials like full-grain leather to withstand the harshest oilfield conditions.

Let's discuss your requirements and ensure your workforce is equipped for safety and performance.

Contact us today for a consultation to get a quote or learn more about our product range.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How can you ensure consistent comfort in work boots? Focus on Fit, Materials & Ergonomics

- What are alternatives to heavy duty work boots? Find the Right Fit for Comfort & Safety

- What certification standard do all work boots meet? Your Guide to ASTM F2413 & Beyond

- Why is safety the most critical aspect of a work boot? Protect Your Workforce from Hazards

- What tips can help ensure a proper fit for work boots? A Guide to All-Day Comfort & Safety

- What should you do when your work boots no longer serve their purpose? Don't Gamble with Your Safety

- What are the long-term benefits of proper firefighting boot selection? Ensure Career Longevity & Safety

- What issues can arise when women wear men's work boots? Avoid Pain and Safety Risks