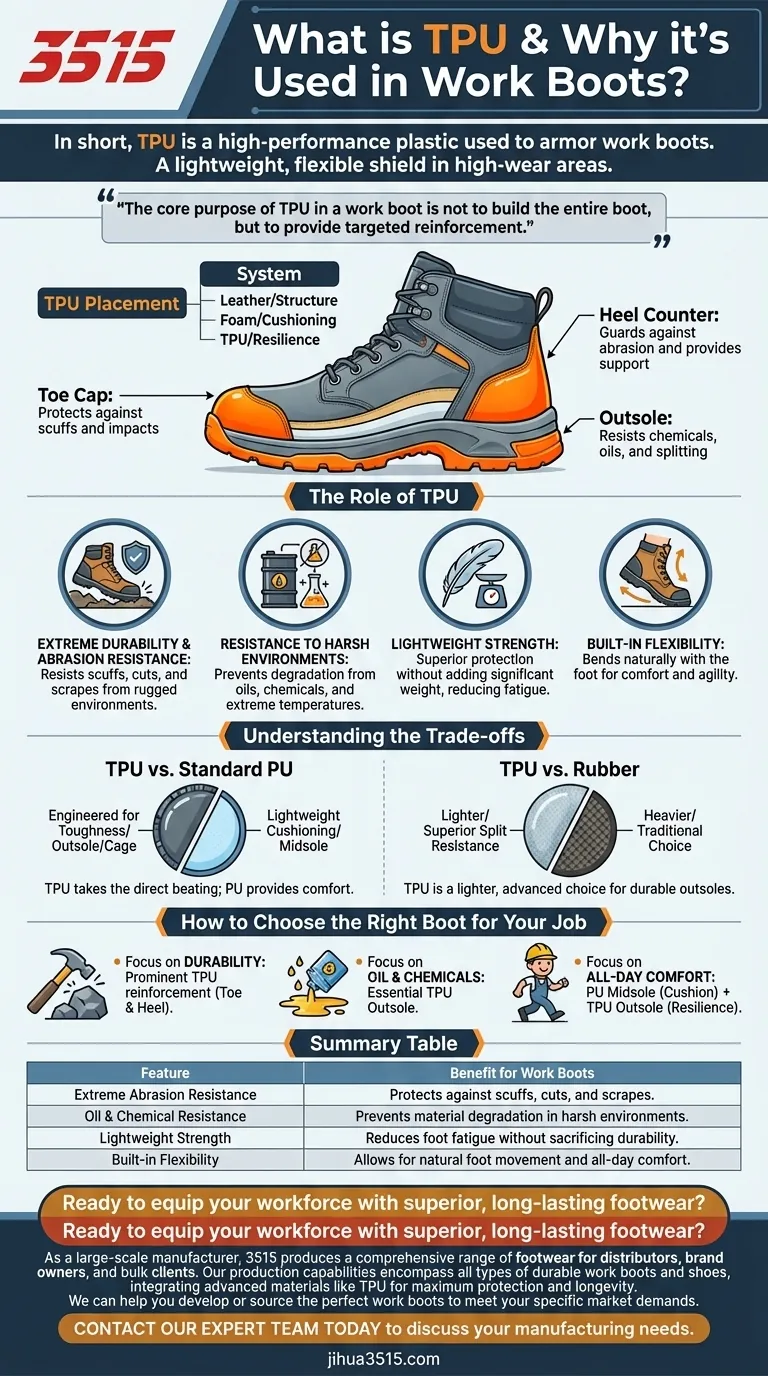

In short, TPU is a high-performance plastic used to armor work boots. Thermoplastic Polyurethane (TPU) is a synthetic material prized for its exceptional durability, flexibility, and resistance to abrasion, oils, and chemicals. It is strategically placed in high-wear areas of a boot—like the toe, heel, and outsole—to drastically increase its lifespan and protective capabilities without adding significant weight.

The core purpose of TPU in a work boot is not to build the entire boot, but to provide targeted reinforcement. It acts as a lightweight, flexible shield in the exact places where a boot endures the most punishment.

The Role of TPU in Modern Work Boots

Think of a work boot as a system. While leather provides structure and comfort, and foam provides cushioning, TPU is the specialized component added for resilience against harsh conditions.

Extreme Durability and Abrasion Resistance

TPU has a very high resistance to wear and tear. When applied to a boot's toe cap or heel counter, it protects the underlying material from scuffs, cuts, and scrapes caused by rugged terrain or sharp debris. It also resists splitting, a common failure point in lower-quality soles.

Resistance to Harsh Environments

Standard boot materials can degrade when exposed to certain substances. TPU is highly resistant to common industrial hazards like oils and chemicals, preventing the material from breaking down and extending the boot's life. It also performs well in extreme temperatures.

Lightweight Strength

Traditionally, adding durability meant adding weight, usually with thick rubber. TPU offers a modern alternative, providing comparable or even superior abrasion resistance at a fraction of the weight. This directly translates to less fatigue for the wearer over a long day.

Built-in Flexibility

Despite its toughness, TPU is remarkably flexible. This allows the boot to bend and flex naturally with the movement of your foot. This is a critical feature for comfort and agility, especially in jobs that require frequent crouching, climbing, or walking.

Understanding the Trade-offs: TPU vs. Other Materials

TPU is an excellent material, but its value is best understood by comparing it to other common materials used in work boot construction.

TPU vs. Standard PU (Polyurethane)

TPU is a specific class of polyurethane engineered for maximum toughness. While standard PU is often used in midsoles for its lightweight cushioning and comfort, TPU is used in the areas that take a direct beating, such as the outsole or as an external "cage" around the boot.

TPU vs. Rubber

Rubber is the traditional choice for durable outsoles. However, TPU is generally lighter than rubber and offers superior resistance to splitting and abrasion. This makes TPU a more advanced choice for creating a durable yet lightweight boot.

How to Choose the Right Boot for Your Job

Your specific work environment and daily tasks should dictate whether TPU is a critical feature for you.

- If your primary focus is durability in abrasive environments: Look for boots with prominent TPU reinforcement, especially an external toe cap and heel guard.

- If your primary focus is working around oils and chemicals: A boot with a TPU outsole is essential for ensuring longevity and preventing material degradation.

- If your primary focus is all-day comfort with less fatigue: Seek out a boot that combines a lightweight PU midsole for cushioning with a durable TPU outsole for a balance of comfort and resilience.

Ultimately, choosing a boot with TPU is an investment in a longer-lasting, more protective piece of equipment.

Summary Table:

| Feature | Benefit for Work Boots |

|---|---|

| Extreme Abrasion Resistance | Protects against scuffs, cuts, and scrapes on rugged terrain. |

| Oil & Chemical Resistance | Prevents material degradation in harsh industrial environments. |

| Lightweight Strength | Reduces foot fatigue without sacrificing durability. |

| Built-in Flexibility | Allows for natural foot movement and all-day comfort. |

Ready to equip your workforce with superior, long-lasting footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable work boots and shoes, integrating advanced materials like TPU for maximum protection and longevity.

We can help you develop or source the perfect work boots to meet your specific market demands.

Contact our expert team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- Why are work boots essential for risk-bearing industries? Protect Your Workforce from Severe Hazards

- What are the consequences of neglecting boot size guides and width charts? Avoid Painful Foot Injuries

- What are the core functional features of adventure-style protective boots? Expert Guide to All-Weather Riding Gear

- What are the key design features of traditional engineer boots? Discover the Anatomy of a Workhorse

- What are the advantages of non-safety toe work boots? Boost Comfort & Reduce Fatigue

- What distinguishes heavy duty work boots from regular boots? Safety, Durability & Purpose Explained

- Which material offers the best chemical protection in work boots? PVC is the definitive choice for hazardous liquids.

- What protective functions do industrial-grade safety boots provide in construction and mining? Maximize Worker Safety