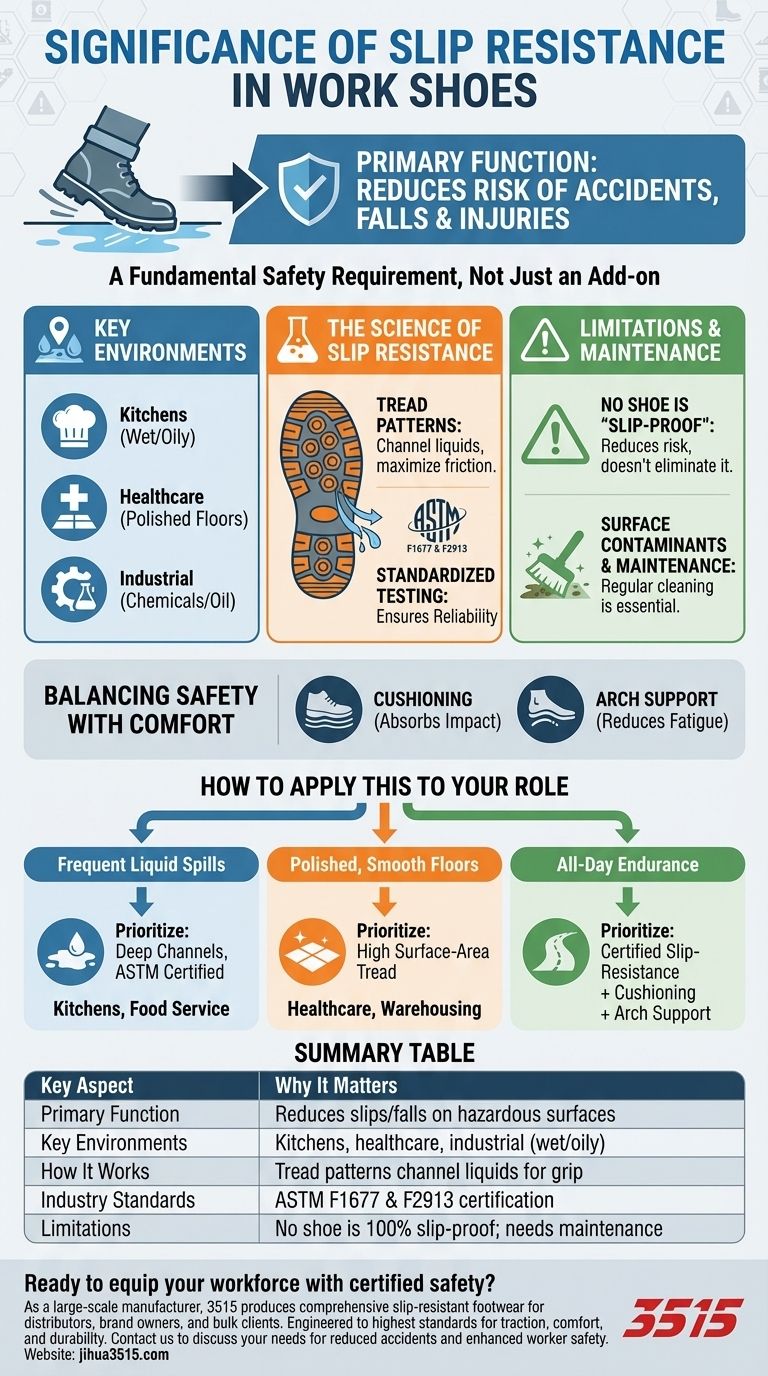

The primary significance of slip resistance in work shoes is to provide critical traction on slick or contaminated surfaces, directly reducing the risk of workplace accidents, falls, and injuries. This feature is not an add-on but a fundamental safety requirement in professions where floors are often wet, oily, or otherwise hazardous, such as in kitchens, healthcare facilities, and industrial settings.

Slips, trips, and falls are a leading cause of preventable workplace injuries. Understanding that slip resistance is an engineered system—not just a single feature—is the key to selecting footwear that provides a genuinely secure foundation in challenging work conditions.

Why Slip Resistance is a Critical Safety System

The right footwear serves as a protective shield against one of the most common workplace hazards. Its importance goes beyond simple grip; it's about creating a stable and safe interaction between the worker and their environment.

The Core Function: Preventing Injury

The fundamental purpose of a slip-resistant outsole is to maximize the friction between the shoe and the floor. This enhanced traction helps prevent the sudden loss of footing that leads to serious injuries from falls.

Key Environments Demanding High Traction

Certain occupations present constant slip hazards. Workers in commercial kitchens (dealing with water, grease, and food spills), healthcare (smooth, polished floors), and industrial plants (oils and chemical contaminants) rely on this feature for their daily safety.

The Science of a Slip-Resistant Outsole

A shoe's ability to resist slipping is determined by the design and material of its outsole. It's a combination of engineering principles working together.

The Role of Tread Patterns

The shape of the outsole's tread is designed to channel liquids away from the bottom of the shoe. Patterns like interlocking hexagons or circles prevent a film of liquid from getting trapped, allowing the sole to make solid contact with the floor.

How Standardized Testing Ensures Reliability

To provide a verifiable measure of safety, work shoes are often tested against industry standards. The two most common are ASTM F1677 and ASTM F2913, which certify a shoe's performance on slippery surfaces, giving you a reliable benchmark for its effectiveness.

Understanding the Limitations and Trade-offs

Even the best-designed footwear has its limits. Recognizing these limitations is just as important as choosing the right shoe in the first place.

No Shoe is Entirely "Slip-Proof"

It is crucial to understand that no shoe can offer 100% protection against slipping. The term "slip-resistant" indicates a significant reduction in risk, not a total elimination of it.

The Impact of Surface Contaminants

The effectiveness of a slip-resistant sole is heavily dependent on the work environment. A clean floor is the first line of defense. Heavy contamination with water, oil, or debris can overwhelm even the best tread patterns.

The Need for Proper Maintenance

To remain effective, both the shoes and the work area require regular cleaning. Removing built-up grime from the outsole's grooves ensures they can function as designed and displace liquids properly.

Balancing Safety with All-Day Comfort

While the outsole is critical for safety, the rest of the shoe dictates whether you can wear it effectively for an entire shift.

Cushioning for Long Hours

Adequate cushioning absorbs impact and enhances overall comfort, which is essential for anyone who spends extended periods standing or walking on hard surfaces.

Arch Support to Reduce Fatigue

Proper arch support is vital for preventing foot fatigue and discomfort over a long workday. It helps distribute pressure evenly and maintains proper foot alignment.

How to Apply This to Your Role

Choosing the right footwear requires matching its specific features to the hazards of your job.

- If you work with frequent liquid spills (e.g., kitchens, food service): Prioritize shoes with certified ASTM slip-resistance ratings and deep, channel-like tread patterns designed to displace water and oil.

- If you work on polished, smooth floors (e.g., healthcare, warehousing): Look for shoes with a high surface-area tread that maximizes contact with the floor, ensuring a stable grip.

- If your primary focus is all-day endurance and safety: Ensure the shoe combines a certified slip-resistant outsole with excellent arch support and cushioning to prevent both accidents and physical fatigue.

Ultimately, selecting the right slip-resistant work shoe is a direct investment in your personal safety and daily well-being on the job.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Primary Function | Reduces risk of slips, trips, and falls on hazardous surfaces. |

| Key Environments | Kitchens, healthcare facilities, industrial plants with wet/oily floors. |

| How It Works | Engineered tread patterns channel liquids away for better grip. |

| Industry Standards | ASTM F1677 & F2913 provide reliable certification for performance. |

| Limitations | No shoe is 100% slip-proof; proper maintenance is essential. |

Ready to equip your workforce with certified safety?

As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered to meet the highest standards for traction, comfort, and durability.

We can help you reduce workplace accidents and enhance worker safety with reliable, high-performance footwear. Contact us today to discuss your specific needs and receive a customized solution.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What does a green triangle symbol on safety footwear mean? Your Guide to Maximum Puncture & Impact Protection

- Why is expert help recommended when selecting safety shoes? Ensure Perfect Fit & Hazard Protection

- How is puncture resistance evaluated in footwear soles? Balance Protection, Comfort & Safety

- What do the markings on ASTM-compliant safety shoes indicate? Decode the Safety Labels for Maximum Protection

- What are the conditions faced by employees in meatpacking and poultry slaughter plants? Navigating Pervasive Slip Hazards