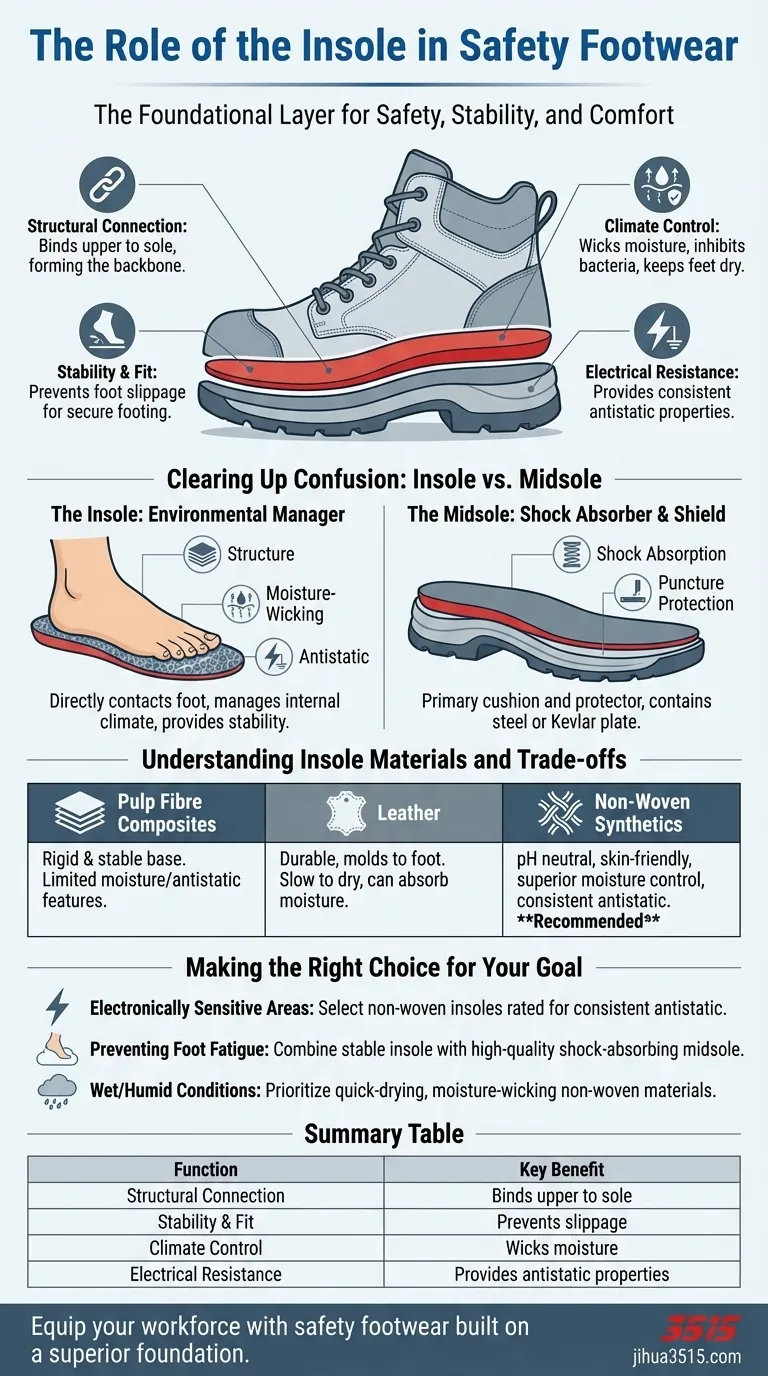

In safety footwear, the insole is the foundational layer that directly interfaces with your foot and the structure of the boot. It is not merely a comfort liner; it serves a critical threefold purpose. The insole connects the boot's upper to its sole, manages the internal climate by wicking moisture, and provides crucial stability and electrical properties required for a safe working environment.

While many focus on the steel toe or the rugged outsole, the insole is the unsung hero of safety footwear. Its primary role is to create a stable, dry, and electrostatically safe environment for your foot, working in tandem with the midsole, which handles shock absorption and puncture protection.

The Insole's Foundational Role

The insole is the core platform of the boot, responsible for creating the immediate environment in which your foot operates for hours at a time. Its functions go far beyond simple cushioning.

Structural Connection

The insole, sometimes called the inner sole, is the component that binds the upper part of the boot (the shaft) to the sole assembly. It forms the backbone of the footwear's construction.

Stability and Fit

By filling the space between your foot and the boot's footbed, the insole prevents your foot from slipping inside the boot. This ensures a stable footing and prevents an unnatural walking gait that can lead to fatigue or injury.

Climate and Hygiene Control

A key function of the insole is moisture management. High-quality insoles are designed to be breathable, pulling sweat away from the foot to keep it dry. This quick-drying capability is essential for inhibiting the growth of bacteria and maintaining foot health.

Electrical Resistance

In many safety applications, controlling static electricity is paramount. The insole plays a vital role in ensuring the boot's overall contact resistance, providing consistent antistatic properties to safely discharge static buildup.

Clearing Up a Common Confusion: Insole vs. Midsole

It is easy to confuse the insole with the midsole, but they perform distinct and separate jobs. Understanding the difference is key to evaluating safety footwear properly.

The Insole: Your Foot's First Contact

Think of the insole as the environmental manager. Its job is to provide a stable, dry, and hygienic platform that directly contacts your foot. Its materials focus on structure, moisture-wicking, and antistatic performance.

The Midsole: The Shock Absorber and Shield

The midsole is located beneath the insole, sandwiched between it and the outsole. This is the boot's primary shock absorber and protector. It is often made from materials like polyurethane (PU), foam, or gel to cushion impacts. In puncture-resistant boots, the protective plate made of steel or Kevlar is integrated into this midsole layer.

How They Work Together

The insole creates the optimal internal environment, while the midsole absorbs the heavy impacts and protects you from sharp objects from below. A failure in either component compromises the boot's overall safety and comfort.

Understanding Insole Materials and Their Trade-offs

The material used for an insole directly impacts its performance, durability, and suitability for specific environments.

Pulp Fibre Composites

These are common, cost-effective materials used to create a rigid and stable base for the boot. While functional, they typically lack advanced moisture-wicking or antistatic capabilities.

Leather

Leather is a traditional choice known for its durability and ability to mold to the shape of the foot over time. However, it can absorb moisture and be slow to dry, which can be a drawback in wet conditions.

Non-Woven Synthetics

Modern, high-performance insoles are often made from non-woven synthetic materials. These are engineered to be pH neutral and skin-friendly, offering superior moisture control and quick-drying properties. Critically, they also provide the most consistent and reliable antistatic properties.

Making the Right Choice for Your Goal

Understanding the insole's function helps you select footwear that truly meets the demands of your job.

- If your primary focus is working in electronically sensitive areas: You must select boots with non-woven insoles specifically rated for their consistent antistatic properties.

- If your primary focus is preventing foot fatigue on hard surfaces: Look for a boot that combines a stable, supportive insole with a high-quality, shock-absorbing midsole.

- If your primary focus is working in wet or humid conditions: Prioritize footwear with insoles made from quick-drying, moisture-wicking non-woven materials to maintain foot health and prevent bacterial growth.

Ultimately, a high-performance insole is the critical foundation for all-day safety, stability, and comfort.

Summary Table:

| Function | Key Benefit |

|---|---|

| Structural Connection | Binds the upper to the sole, forming the boot's backbone. |

| Stability & Fit | Prevents foot slippage, ensuring a secure and stable footing. |

| Climate Control | Wicks moisture to keep feet dry and inhibit bacterial growth. |

| Electrical Resistance | Provides consistent antistatic properties for safe static discharge. |

Equip your workforce with safety footwear built on a superior foundation.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of footwear, ensuring every pair features a high-performance insole for optimal stability, hygiene, and electrical safety.

Contact us today to discuss your safety footwear needs and benefit from our manufacturing expertise.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear