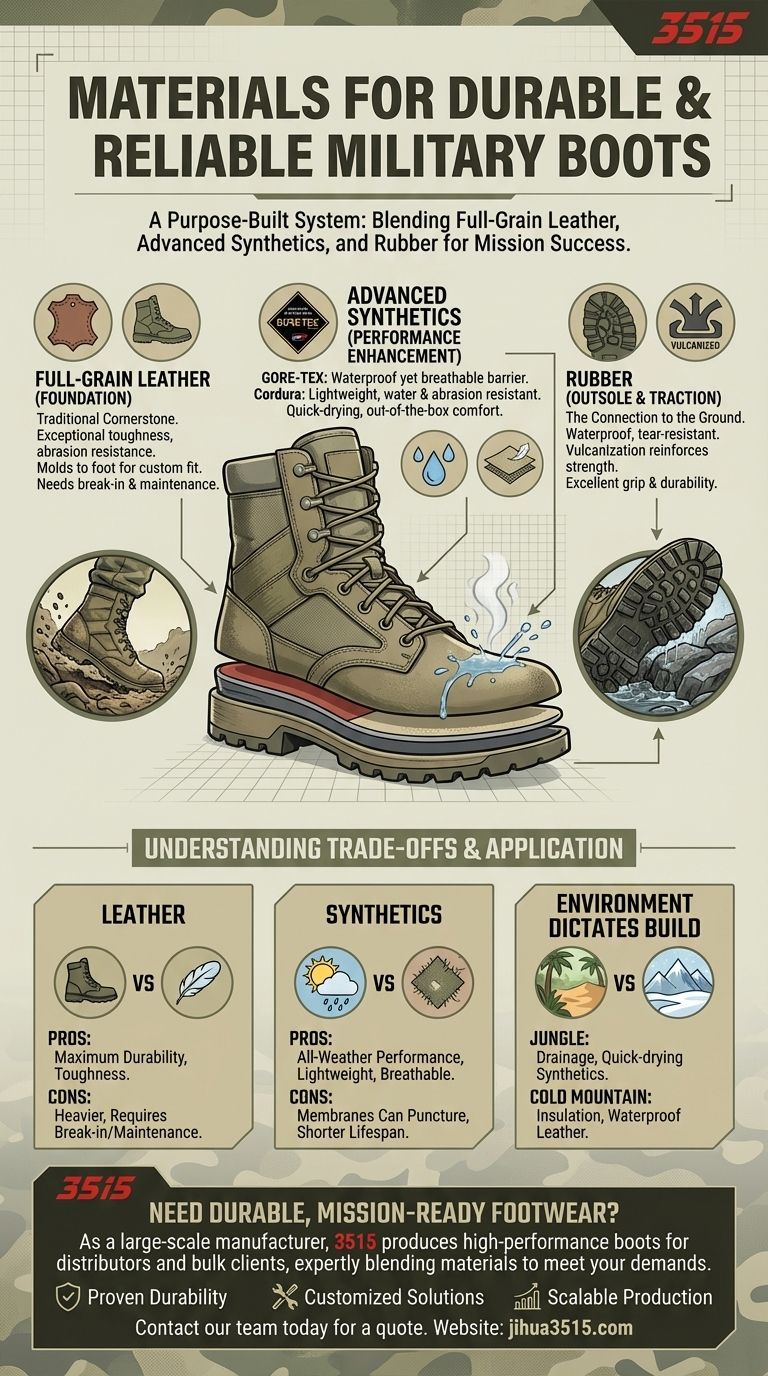

For decades, the foundation of durable military boots has been high-quality leather, but modern designs now strategically integrate advanced synthetic materials and rubber. This combination ensures boots are not just tough, but also optimized for specific environmental challenges like water, heat, and rough terrain.

The most reliable military boots do not rely on a single "best" material. Instead, they represent a purpose-built system, combining the proven durability of full-grain leather with the specialized performance of synthetics and rubber to meet mission-specific demands.

Why Material Selection is Critical

The materials used in a military boot are the primary determinants of its performance. This choice directly impacts everything from an operator's comfort and foot health to the boot's overall lifespan and protective capabilities in harsh environments.

The Foundation: High-Quality Leather

Full-grain leather is the traditional cornerstone of duty boots for good reason. It offers an exceptional balance of toughness, abrasion resistance, and natural breathability, molding to the wearer's foot over time for a custom fit.

The Role of Advanced Synthetics

Modern boots frequently incorporate synthetic fabrics to enhance performance. GORE-TEX is used to create a waterproof yet breathable barrier, while materials like Cordura offer excellent water and abrasion resistance in a lighter package, ideal for hot, dry climates.

The Unseen Hero: Rubber

The outsole of a boot is its connection to the ground, and rubber is the material of choice for this critical component. Its natural waterproofing and tear resistance are often enhanced through vulcanization, a process that reinforces its strength and makes it highly resistant to wear.

Understanding the Trade-offs

No single material is perfect for every situation. Understanding the inherent compromises in material selection is key to appreciating why different boots are built for different purposes.

Leather: Durability vs. Weight

While incredibly durable, a full-grain leather boot is typically heavier than a synthetic counterpart. It also requires a break-in period and regular maintenance to preserve its protective qualities.

Synthetics: Performance vs. Lifespan

Waterproof-breathable membranes like GORE-TEX provide outstanding performance from day one. However, these membranes can be punctured or wear out over time, potentially compromising the boot's waterproofing faster than a well-maintained leather upper.

Environment Dictates the Build

The ideal material mix is entirely dependent on the operational environment. A boot designed for jungle warfare will prioritize drainage and quick-drying synthetics, while a boot for cold mountain environments will focus on insulation and robust, waterproofed leather.

How to Apply This to Your Needs

Choosing the right boot means matching its materials to your primary goal.

- If your primary focus is maximum durability and traditional toughness: A boot constructed primarily from full-grain leather is the most proven and reliable option.

- If your primary focus is all-weather performance and out-of-the-box comfort: Look for a hybrid boot that combines a leather frame with a GORE-TEX or other waterproof-breathable membrane.

- If your primary focus is lightweight agility in hot or dry conditions: A boot that strategically replaces leather with durable nylon fabrics like Cordura will provide the best results.

Ultimately, understanding the role of each material empowers you to select a boot that is not just durable, but perfectly suited for your specific mission.

Summary Table:

| Material | Primary Function | Key Characteristics |

|---|---|---|

| Full-Grain Leather | Foundation & Durability | Exceptional toughness, abrasion resistance, molds to foot |

| Advanced Synthetics (e.g., GORE-TEX, Cordura) | Performance Enhancement | Waterproof, breathable, lightweight, quick-drying |

| Rubber | Outsole & Traction | Waterproof, tear-resistant, durable, excellent grip |

Need Durable, Mission-Ready Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of tactical and military footwear, expertly blending full-grain leather, advanced synthetics, and durable rubber to meet your specific operational demands.

We deliver:

- Proven Durability: Boots built with high-quality materials for long-lasting performance.

- Customized Solutions: Designs tailored to specific environments and user needs.

- Scalable Production: Reliable supply for large-volume orders.

Let's discuss your requirements. Contact our team today to get a quote or learn more about our capabilities.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

People Also Ask

- What is the primary benefit of walking in military boots with ankle support? Maximize Stability and Prevent Injury

- What are the requirements for Berry-compliant boots? A Guide to 100% USA Sourcing

- What is the range of shaft heights in military boots? Choose the Right Height for Your Mission

- How do military boots impact the quality of work for personnel? Boost Performance & Safety in the Field

- How should military boots be maintained? A Guide to Maximize Durability and Performance

- What are combat boots and their key characteristics? Unmatched Durability & Protection for Demanding Use

- What historical event marked the first use of camouflage in military apparel? The Napoleonic Wars' Tactical Shift

- Are jungle boots waterproof? No, and here's why that's a brilliant design feature.