The outsole of a hiking shoe is the layer of rubber that makes direct contact with the ground. You can judge its traction by physically inspecting the rubber's softness and the depth of its tread pattern, known as lugs, as well as by testing its grip on a hard surface.

The most effective hiking outsole is not simply the hardest or softest; it is the one that strikes the correct balance between durable materials and an intelligent tread design for the specific terrain you intend to conquer.

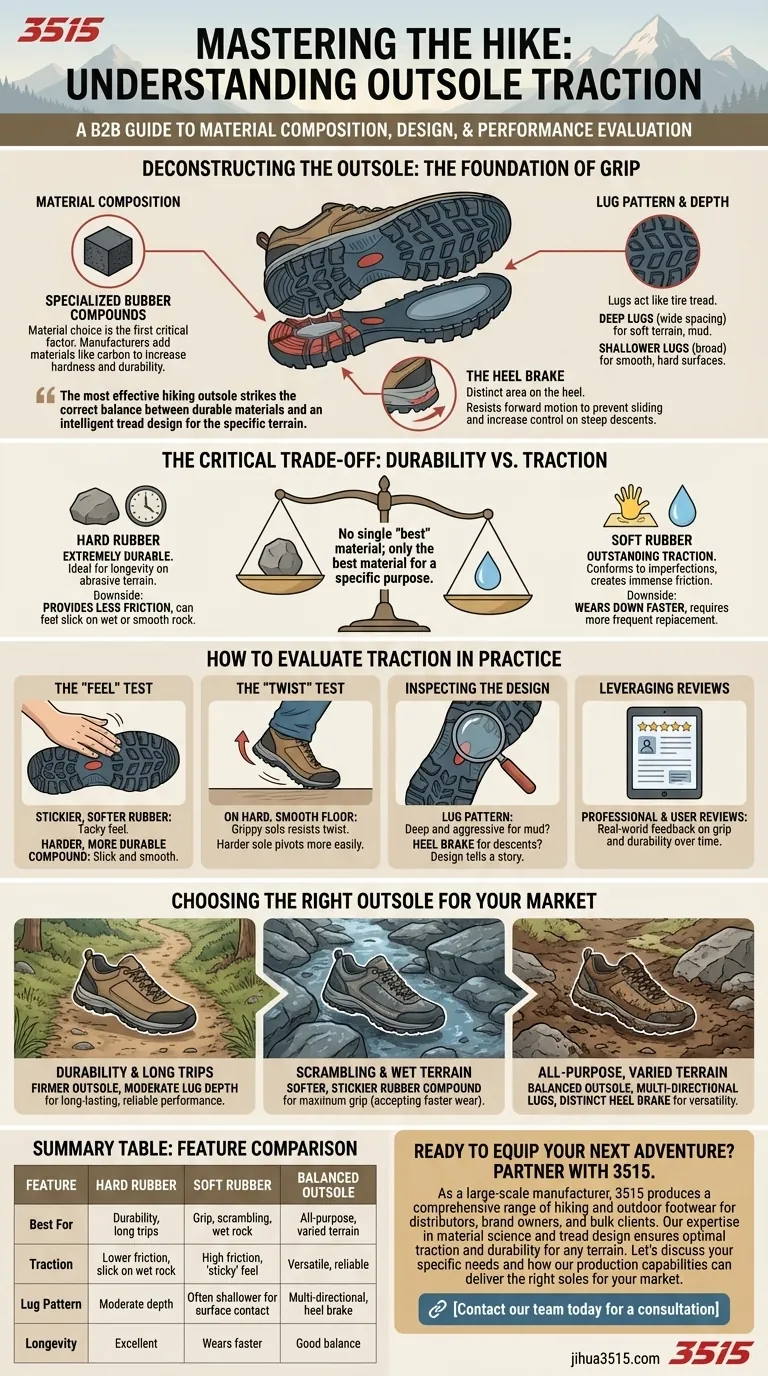

Deconstructing the Outsole: The Foundation of Grip

To truly understand traction, you must look at the two core elements of an outsole: its material composition and its physical design.

Material Composition

The outsole is made from specialized rubber compounds. Some manufacturers add materials like carbon to increase the hardness and durability of the sole.

This material choice is the first critical factor in determining grip.

Lug Pattern and Depth

Lugs are the bumps and channels on the bottom of your shoe that act like the tread on a tire.

Deep, widely-spaced lugs excel at digging into soft terrain like mud or loose dirt, providing mechanical grip. Shallower, broader lugs increase the surface area in contact with the ground, which can improve grip on smooth, hard surfaces like rock slabs.

The Heel Brake

Many hiking shoes feature a distinct "heel brake." This is an area on the heel where the lugs are oriented to resist forward motion.

Its purpose is to help prevent you from sliding and to increase control during steep descents, acting as a crucial safety feature.

The Critical Trade-off: Durability vs. Traction

Understanding the inherent compromise between hard and soft rubber is essential for selecting the right shoe. There is no single "best" material; there is only the best material for a specific purpose.

The Problem with Hard Rubber

A very hard rubber outsole will be extremely durable and resistant to wear and tear. This is ideal for longevity, especially on abrasive terrain.

The downside is that hard rubber provides less friction. It can feel slick and unreliable, particularly on wet or smooth rock surfaces where "stickiness" is paramount.

The Problem with Soft Rubber

A soft, sticky rubber outsole provides outstanding traction. It conforms to micro-imperfections in the rock and creates immense friction, giving you a secure feeling of being glued to the ground.

The drawback is its longevity. Soft rubber wears down significantly faster, meaning you will need to replace the shoes more frequently.

How to Evaluate Traction in Practice

You can combine physical inspection with research to make an informed judgment about a shoe's outsole before you commit.

The "Feel" Test

Simply run your hand over the lugs. A stickier, softer rubber will have a tacky feel, while a harder, more durable compound will feel slick and smooth.

The "Twist" Test

When trying on shoes in a store, stand on a hard, smooth floor. Plant your foot and try to twist it. A grippy sole will resist this motion, while a harder sole may pivot more easily.

Inspecting the Design

Look at the lug pattern. Are the lugs deep and aggressive for muddy trails? Is there a well-defined heel brake for confidence on descents? The design tells a story about the shoe's intended use.

Leveraging Reviews

Professional and user reviews are invaluable. Reviewers often test footwear across hundreds of miles on varied terrain, providing real-world feedback on how the outsole's grip and durability hold up over time.

Choosing the Right Outsole for Your Hike

Your choice should always be dictated by your primary hiking environment and goals.

- If your primary focus is durability and long backpacking trips on established trails: Look for a firmer outsole with moderate lug depth for long-lasting, reliable performance.

- If your primary focus is scrambling and hiking on slick rock or wet terrain: Prioritize a shoe with a softer, stickier rubber compound for maximum grip, accepting that it will wear faster.

- If your primary focus is all-purpose hiking on varied terrain like mud, dirt, and rock: Seek a balanced outsole with multi-directional lugs and a distinct heel brake for versatility.

An effective outsole gives you the confidence to focus on the trail ahead, not on your footing.

Summary Table:

| Feature | Hard Rubber | Soft Rubber | Balanced Outsole |

|---|---|---|---|

| Best For | Durability, long trips | Grip, scrambling, wet rock | All-purpose, varied terrain |

| Traction | Lower friction, slick on wet rock | High friction, 'sticky' feel | Versatile, reliable |

| Lug Pattern | Moderate depth | Often shallower for surface contact | Multi-directional, heel brake |

| Longevity | Excellent | Wears faster | Good balance |

Ready to equip your next adventure with the perfect footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of hiking and outdoor footwear for distributors, brand owners, and bulk clients. Our expertise in material science and tread design ensures optimal traction and durability for any terrain.

Let's discuss your specific needs and how our production capabilities can deliver the right soles for your market.

Contact our team today for a consultation

Visual Guide

Related Products

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What is a trekking shoe? The Essential Guide to Protection & Stability

- How does tread affect outdoor footwear performance? Maximize Traction & Stability

- Are trekking shoes worth it? Essential for Safety and Comfort on the Trail

- What protective role does the sole structure of toe spring shoes play? Master Complex Terrain and Prevent Falls

- What are some alternatives to hunting boots? Hiking, Rubber & Tactical Boots Explained