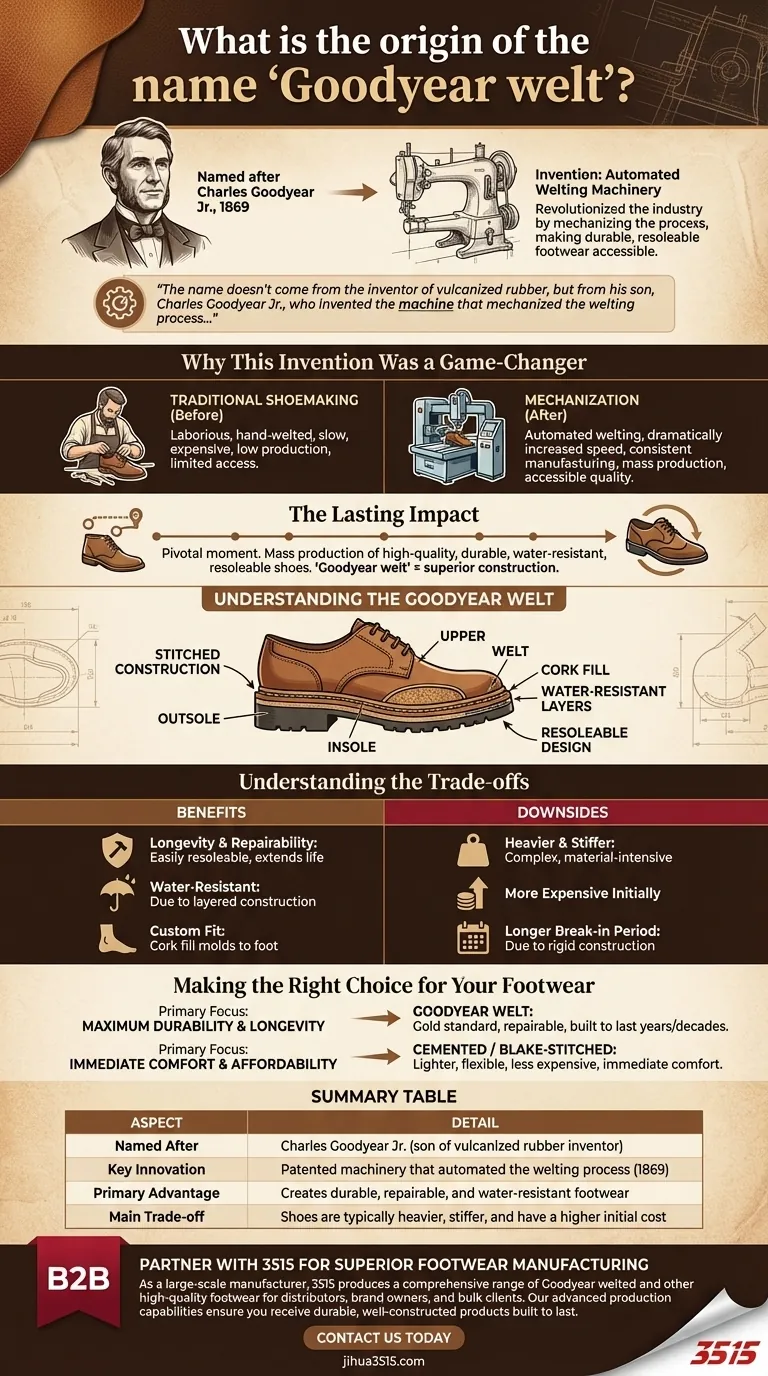

The Goodyear welt is named after Charles Goodyear Jr., the son of the famous inventor of vulcanized rubber. In 1869, Charles Goodyear Jr. patented the specialized machinery that automated the welting process, revolutionizing an industry previously dependent on traditional, time-consuming hand-welting methods. This invention made durable, resoleable footwear accessible on a mass scale.

The name doesn't come from the inventor of vulcanized rubber, but from his son, Charles Goodyear Jr., who invented the machine that mechanized the welting process, making high-quality, repairable footwear widely available.

Why This Invention Was a Game-Changer

The Problem with Traditional Shoemaking

Before this innovation, attaching the sole of a shoe was a laborious process done entirely by hand. A skilled artisan would meticulously stitch the upper, insole, and sole together.

This hand-welted method produced excellent, long-lasting shoes, but it was slow and expensive. The high cost and low production volume placed such footwear out of reach for the average person.

The Solution: Mechanization

Charles Goodyear Jr.'s machinery automated the most critical step: attaching the welt. The welt is a strip of leather that runs along the perimeter of the shoe's outsole.

The machine stitches this welt to both the shoe's upper and insole. The outsole is then stitched directly to the welt, rather than through the insole. This mechanical process dramatically increased the speed and consistency of manufacturing.

The Lasting Impact

This mechanization was a pivotal moment in footwear history. It allowed for the mass production of high-quality, durable, and water-resistant shoes that could be resoled multiple times, extending their life significantly. The "Goodyear welt" became synonymous with this superior construction method.

Understanding the Trade-offs

The Benefits of a Goodyear Welt

The primary advantage is longevity and repairability. Since the outsole is stitched to the welt and not directly to the upper, a cobbler can easily remove the old sole and attach a new one without compromising the shoe's structure.

This method also creates a more water-resistant shoe due to the layers between the insole and outsole. The cavity created by the welt is typically filled with cork, which molds to the wearer's foot over time for a custom fit.

The Downsides

Goodyear welting is a more complex and material-intensive process compared to modern methods like cementing (gluing) soles. This results in a shoe that is typically heavier, stiffer, and more expensive initially.

The break-in period for a Goodyear-welted shoe can also be longer due to its rigid construction.

Making the Right Choice for Your Footwear

When evaluating footwear, understanding the construction method helps you align your purchase with your needs.

- If your primary focus is maximum durability and longevity: A Goodyear welt is the gold standard, as it is built to be repaired and last for years, if not decades.

- If your primary focus is immediate comfort and affordability: A cemented or Blake-stitched shoe might be a better choice, as they are typically lighter, more flexible out of the box, and less expensive.

Ultimately, the Goodyear welt represents a benchmark in quality construction, named for the innovator who made it accessible to the world.

Summary Table:

| Aspect | Detail |

|---|---|

| Named After | Charles Goodyear Jr. (son of the vulcanized rubber inventor) |

| Key Innovation | Patented machinery that automated the welting process (1869) |

| Primary Advantage | Creates durable, repairable, and water-resistant footwear |

| Main Trade-off | Shoes are typically heavier, stiffer, and have a higher initial cost |

Partner with 3515 for Superior Footwear Manufacturing

As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear welted and other high-quality footwear for distributors, brand owners, and bulk clients. Our advanced production capabilities ensure you receive durable, well-constructed products built to last.

Contact us today to discuss your manufacturing needs and elevate your footwear line.

Visual Guide

Related Products

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Durable & Breathable Training Shoes for Custom Brands

People Also Ask

- What are the characteristics of business casual sneakers? Master the Polished & Professional Look

- Are sneakers acceptable in a business casual workplace? How to Choose the Right Style

- How does leather compare to other shoe materials in terms of durability and comfort? A Material Guide for Footwear

- How does top-grain leather differ from full-grain? Choose the Right Leather for Your Products

- Why are sneakers now accepted in office environments? The Shift to Modern Professionalism