Finding the most comfortable safety shoe is not about a single brand or model, but about matching specific design principles to your foot and work environment. While lists of popular shoes exist, true comfort comes from understanding the interplay of fit, cushioning, weight, and the type of protection you need.

The core principle of safety shoe comfort is achieving a balance between protection and ergonomics. The most comfortable shoe for you will have the right fit, a cushioning system suited for your work surfaces, and be made of materials that reduce fatigue over a long day.

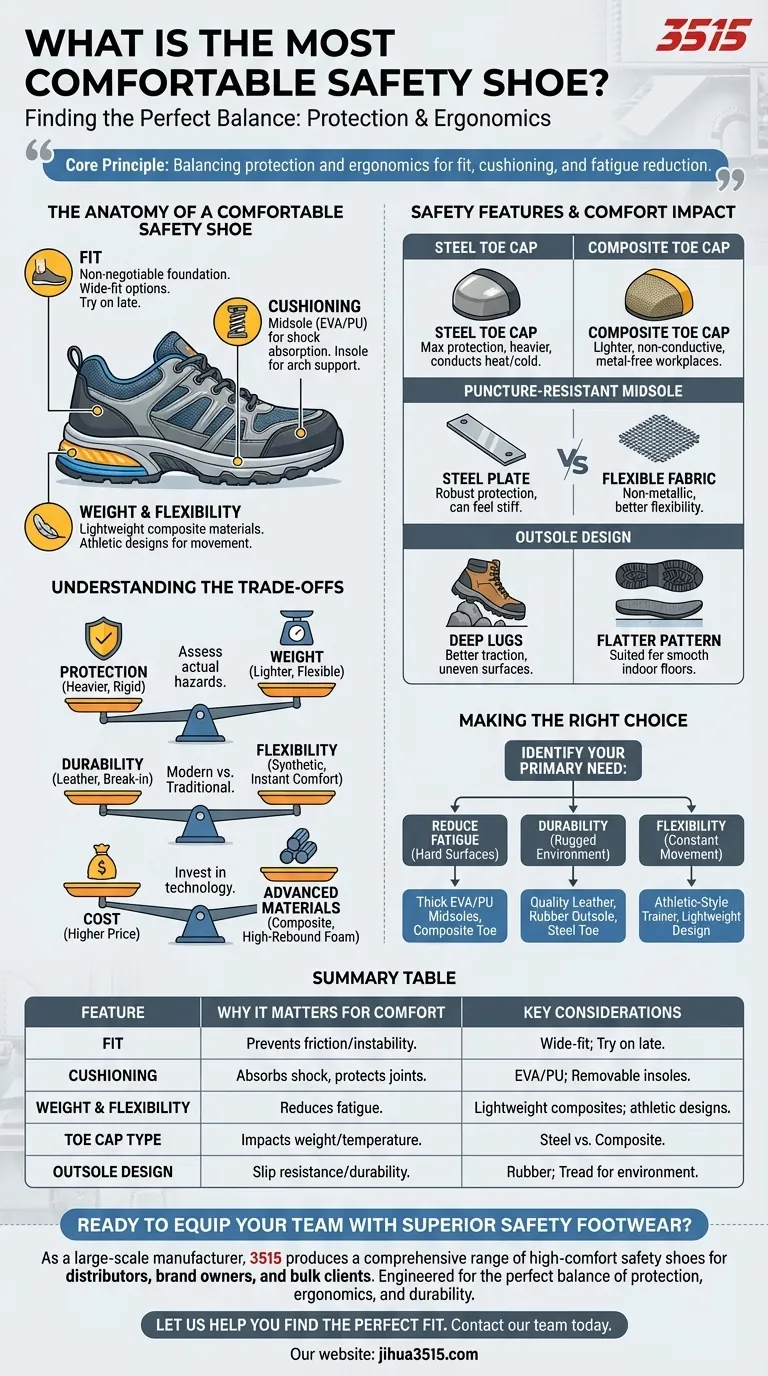

The Anatomy of a Comfortable Safety Shoe

Lasting comfort is engineered from several key components working together. Ignoring any one of these can lead to fatigue and pain, regardless of the brand name.

Fit is Non-Negotiable

A proper fit is the foundation of comfort. A shoe that is too tight restricts blood flow, while one that is too loose allows your foot to slide, causing friction and instability.

Look for brands that offer wide-fit options, like the Toe Guard Storm, if you have broader feet. Always try on shoes at the end of the day when your feet are slightly swollen to get the most accurate size.

The Cushioning System: Midsole and Insole

The midsole is the engine of comfort, responsible for shock absorption. Materials like EVA foam or Polyurethane (PU) compress with each step, cushioning the impact on your joints.

A quality insole can further enhance comfort and provide arch support. Many safety shoes come with removable insoles, allowing you to insert your own custom orthotics if needed.

Overall Weight and Flexibility

A heavy shoe requires more energy to lift with every step, leading to significant fatigue by the end of your shift. Modern safety shoes often use lighter materials to combat this.

Safety trainers, like those from Caterpillar or Puma, use lightweight composite materials and flexible designs that mimic athletic shoes, making them ideal for jobs requiring constant movement.

How Safety Features Impact Comfort

The very elements that protect you can also be sources of discomfort if not chosen carefully. Understanding the differences is critical.

The Protective Toe Cap: Steel vs. Composite

Steel toes offer maximum protection against impact and compression. However, they are heavier than alternatives and can conduct heat and cold, which can be a problem in extreme temperature environments.

Composite toes are made from non-metal materials like carbon fiber, plastic, or Kevlar. They are significantly lighter, don't conduct temperature, and are ideal for workplaces with metal detectors.

Puncture-Resistant Midsoles

Many safety shoes include a protective plate in the midsole to prevent sharp objects from piercing the sole. While steel plates offer robust protection, they can make the shoe feel stiff.

Flexible, non-metallic anti-perforation fabrics are a more modern alternative that provides protection without severely limiting the shoe's flexibility.

Outsole Design and Material

The outsole must provide slip resistance and durability. A quality rubber outsole offers excellent grip and longevity, which is a key feature in both high-performance walking shoes and safety footwear.

The pattern of the tread is also important. Deeper lugs provide better traction on uneven surfaces, while a flatter pattern may be better suited for smooth indoor floors.

Understanding the Trade-offs

Choosing a safety shoe always involves balancing competing priorities. Being aware of these trade-offs will help you make a more informed decision.

Protection vs. Weight

As a general rule, the higher the level of protection (e.g., metatarsal guards, extreme puncture resistance), the heavier and more rigid the shoe will be. You must assess the actual hazards of your job and choose the appropriate level of protection to avoid unnecessary weight.

Durability vs. Flexibility

Traditional leather boots, like some from Dr. Martens, offer exceptional durability but often require a significant "break-in" period to become comfortable. In contrast, modern synthetic trainer-style shoes offer instant flexibility but may not withstand the same level of abuse.

Cost vs. Advanced Materials

The lightest and most comfortable safety shoes often utilize advanced materials like composite toes, high-rebound cushioning foams, and flexible puncture-resistant fabrics. These technologies typically come at a higher price point than their traditional, heavier counterparts.

Making the Right Choice for Your Goal

Select your footwear by first identifying your most critical daily need.

- If your primary focus is reducing fatigue on hard surfaces (concrete, warehouse floors): Prioritize shoes with thick EVA or PU midsoles for maximum shock absorption and a lightweight composite toe.

- If your primary focus is durability in a rugged environment (construction, outdoors): Look for boots with high-quality leather uppers, a rugged rubber outsole, and the robust protection of a steel toe.

- If your primary focus is flexibility and constant movement (logistics, light assembly): Choose an athletic-style safety trainer that emphasizes a lightweight design and a flexible sole.

By focusing on these core principles of fit, materials, and construction, you can find a safety shoe that provides protection without sacrificing all-day comfort.

Summary Table:

| Feature | Why It Matters for Comfort | Key Considerations |

|---|---|---|

| Fit | Foundation of comfort; prevents friction and instability. | Look for wide-fit options; try on shoes at the end of the day. |

| Cushioning (Midsole/Insole) | Absorbs shock with each step, protecting joints. | EVA or PU midsoles; removable insoles for custom orthotics. |

| Weight & Flexibility | Reduces energy expenditure and fatigue over long shifts. | Lightweight composite materials; athletic-style designs. |

| Toe Cap Type | Impacts weight and temperature conduction. | Steel toe (max protection) vs. Composite toe (lighter, non-conductive). |

| Outsole Design | Provides slip resistance and durability on various surfaces. | Quality rubber; tread pattern suited to your work environment. |

Ready to Equip Your Team with Superior Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-comfort safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of occupational footwear, engineered with the perfect balance of protection, ergonomics, and durability to keep your workforce safe and productive all day long.

Let us help you find the perfect fit for your needs. Contact our team today to discuss your requirements and request a catalog.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- Why is expert help recommended when selecting safety shoes? Ensure Perfect Fit & Hazard Protection

- What types of workplace hazards require protective footwear? Essential Guide for Workplace Safety

- What materials are used in the construction of these boots? A Guide to Velour Leather, Textile & PU Soles

- What should warehouse work shoes include for safety? Essential Features for All-Day Protection

- What do the markings on ASTM-compliant safety shoes indicate? Decode the Safety Labels for Maximum Protection