At its core, the main difference between carbon toe and steel toe work boots is the material used for the protective cap. Steel toe caps are made from steel, while carbon toe caps are made from a modern, lightweight composite material that includes carbon fiber. This material difference creates significant trade-offs in weight, conductivity, and comfort.

The decision between carbon and steel is not about which is universally "better," but about understanding which material's specific properties—protection, weight, and conductivity—are the right tool for your specific work environment.

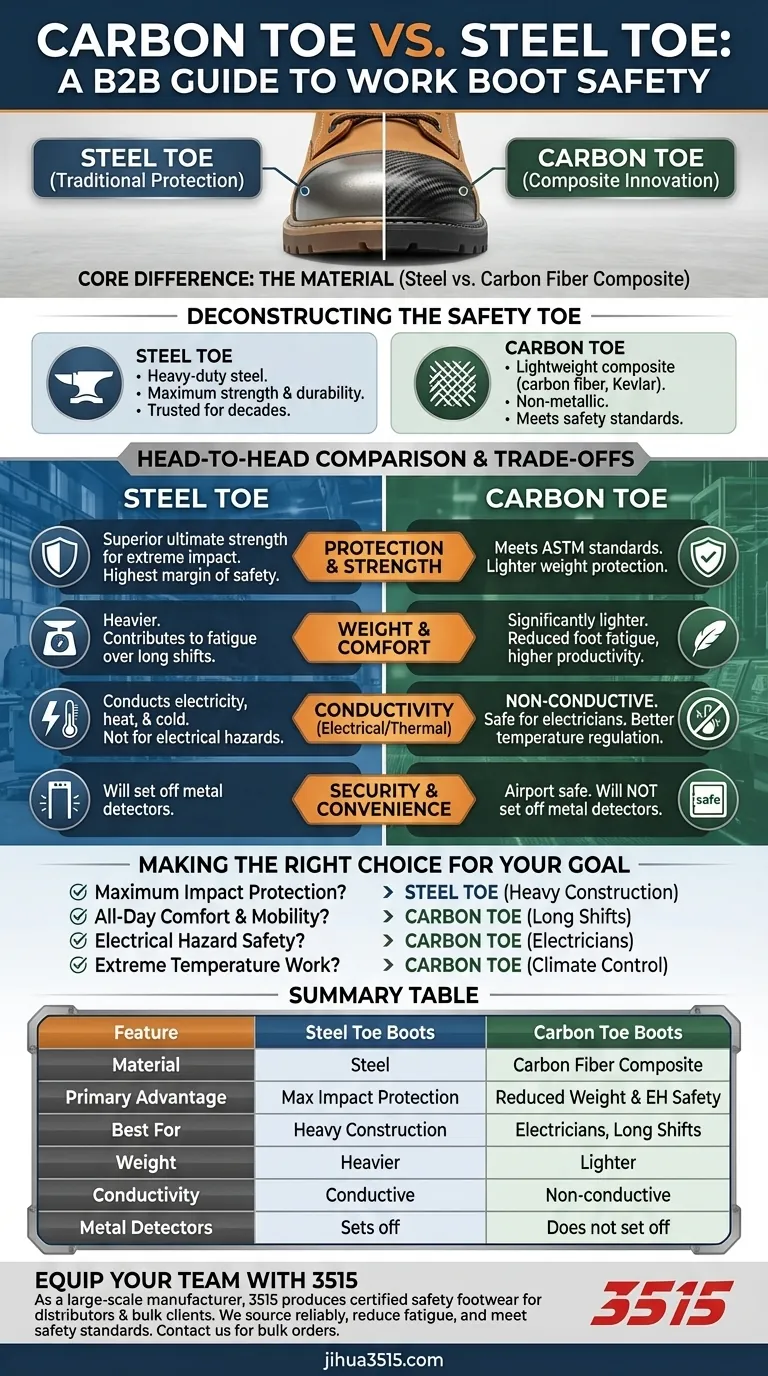

Deconstructing the Safety Toe: Why the Material Matters

The protective toe cap is the heart of a safety boot. While both steel and carbon fiber designs must meet the same fundamental ASTM safety standards for impact and compression, the material they use dictates their performance in real-world conditions.

What is a Steel Toe?

A steel toe is the traditional standard for safety footwear. It's a heavy-duty cap made of steel that provides robust protection against impact from falling objects and compression.

This material choice makes the boot exceptionally strong and durable, which is why it has been trusted for decades in demanding fields like construction.

What is a Carbon Toe?

A carbon toe is a type of composite safety toe. These caps are made from non-metal materials, weaving together strong synthetic fibers like carbon fiber and sometimes Kevlar.

The primary benefit of this construction is that it is significantly lighter than steel while still meeting the required safety standards.

The Composite Family

It's important to understand that carbon fiber is a premium type of composite toe. The key principle of all composite toes is that they are non-metallic, which gives them a distinct set of advantages over steel.

Head-to-Head Comparison: Carbon vs. Steel

Choosing the right boot means evaluating how each material performs across the factors that matter most during your workday.

Protection and Strength

Steel generally offers superior ultimate strength against extreme impact and sharp objects. While both types must pass ASTM F2413-18 standards, steel provides a higher margin of safety against the most severe hazards.

Weight and Comfort

This is the most significant advantage for carbon toe boots. They are noticeably lighter than steel toe boots, which reduces foot fatigue over long shifts. This increased comfort can directly contribute to higher productivity and less strain on your body.

Electrical and Thermal Conductivity

Because they are non-metallic, carbon and other composite toes do not conduct electricity. This makes them the only safe choice for electricians or anyone working in an electrical hazard environment.

Similarly, they do not conduct heat or cold, keeping your feet more comfortable in extreme temperatures. Steel, being a metal, will readily conduct both.

Security and Metal Detectors

Composite toes like carbon fiber will not set off metal detectors. This is a crucial convenience for workers who frequently pass through security checkpoints in sensitive facilities.

Understanding the Trade-offs

There is no perfect, one-size-fits-all safety toe. Each material comes with inherent compromises you must consider for your specific role.

The Reality of Impact Resistance

While carbon toe boots meet official safety requirements, steel provides a greater buffer against failure in the event of an extreme, beyond-specification impact. For environments with a constant risk of very heavy falling objects, steel offers the most robust protection available.

The Weight Penalty of Steel

The superior strength of steel comes at a cost: weight. The added ounces in each boot may seem minor, but over thousands of steps in a workday, this extra weight contributes directly to fatigue in your feet, legs, and back.

Making the Right Choice for Your Goal

Select your boot based on the primary demands of your job, not just a single feature.

- If your primary focus is maximum impact protection: Steel toe boots provide the highest level of defense, making them ideal for heavy construction and industrial sites.

- If your primary focus is all-day comfort and mobility: Carbon toe boots offer significant weight savings that reduce fatigue, perfect for long shifts with constant walking.

- If your primary focus is electrical hazard safety: A non-metallic carbon or composite toe is essential, as it eliminates the risk of electrical conductivity.

- If your primary focus is working in extreme temperatures: The non-conductive thermal properties of a carbon toe will keep your feet more comfortable in severe heat or cold.

Ultimately, choosing the right safety boot is about selecting the specialized equipment that keeps you safe, comfortable, and effective on the job.

Summary Table:

| Feature | Steel Toe Boots | Carbon Toe Boots |

|---|---|---|

| Material | Heavy-duty steel | Lightweight carbon fiber composite |

| Primary Advantage | Maximum impact protection | Reduced weight & electrical hazard safety |

| Best For | Heavy construction, industrial sites | Electricians, long shifts, extreme temperatures |

| Weight | Heavier | Lighter |

| Conductivity | Conducts electricity & temperature | Non-conductive |

| Metal Detectors | Will set off | Will not set off |

Ready to Equip Your Team with the Right Safety Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots, including both steel toe and carbon/composite toe models, ensuring you get the perfect balance of protection, comfort, and compliance for your specific industry needs.

We help you:

- Source Reliably: Get high-quality, ASTM-certified boots in large quantities.

- Reduce Fatigue: Offer your end-users lighter composite boots for enhanced productivity.

- Meet Safety Standards: Ensure every pair meets the necessary impact and compression requirements.

Let's discuss your bulk order requirements. Contact our team today for expert guidance and competitive pricing.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

People Also Ask

- What is the purpose of steel toe caps in firefighter boots? Maximum Impact & Crush Protection

- What are the primary concerns when choosing between steel-toe and soft-toe boots? Match Your Boot to Your Job's Hazards

- Can steel toe boots be worn in hot conditions? Yes, with the right breathable design.

- Why is impact-resistant toe protection a core safety feature? Essential Protection for Heavy Loading

- What is the core protective function of steel-toe safety shoes in preventing lower limb injuries caused by chainsaws?

- Why is it important to wear steel toe work boots? Maximum Impact Protection for Hazardous Work

- Do moc toe boots have steel toe? Get Durable, Safety-Compliant Footwear

- What are the advantages of steel toe boots? Maximum Protection, Lower Cost & Streamlined Design