Choosing the right work boot outsole is a critical decision that directly impacts your safety, comfort, and performance on the job. The outsole is your primary point of contact with your work surface, meaning its material and design dictate your stability, protection from hazards, and resistance to daily fatigue. Selecting the wrong one can lead to everything from minor discomfort to a life-altering injury.

The outsole is not just the bottom of your boot; it is a specialized piece of equipment. Matching its properties—like grip, durability, and resistance—to your specific work environment is the single most important factor in work boot selection.

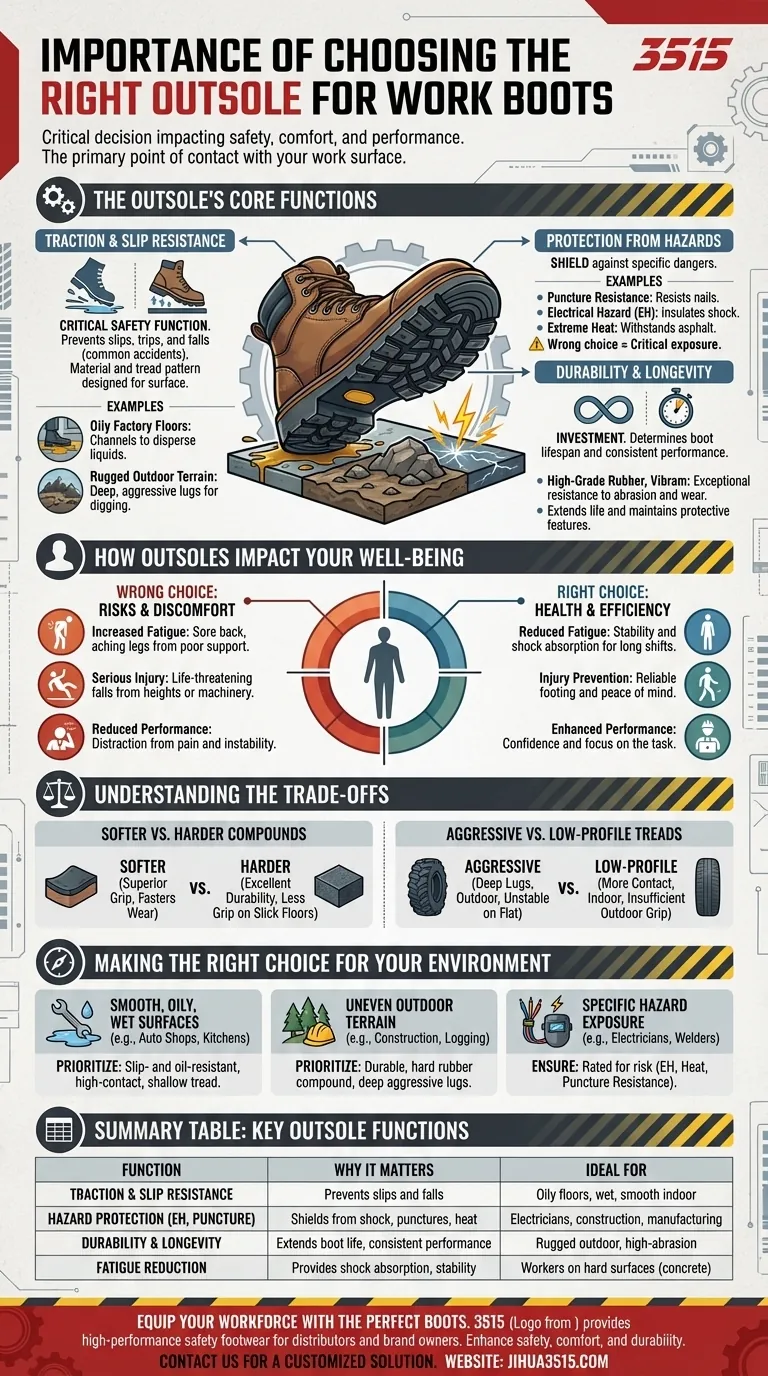

The Outsole's Core Functions

The importance of the outsole is best understood by breaking down its three fundamental responsibilities: providing traction, protecting from hazards, and ensuring long-term durability.

Traction and Slip Resistance

This is the outsole's most critical safety function. The material composition and tread pattern work together to prevent slips, trips, and falls, which are among the most common workplace accidents.

Different surfaces demand different designs. An outsole designed for oily factory floors will have channels to disperse liquids, while one for rugged outdoor terrain will feature deep, aggressive lugs for digging into soft ground.

Protection from Hazards

Beyond traction, the outsole serves as a shield. Specific materials are engineered to resist punctures from nails, provide insulation from electrical shock (EH-rated), or withstand extreme heat from sources like asphalt.

Choosing a sole that is not rated for the hazards in your environment leaves you critically exposed to injury.

Durability and Longevity

A work boot is an investment, and the outsole determines how long that investment lasts. Materials like high-grade rubber or renowned compounds like Vibram are known for their exceptional resistance to abrasion and wear.

A durable outsole not only extends the life of the boot but also maintains its protective features over time, ensuring you get consistent performance and value.

How Outsoles Impact Your Well-being

The effects of a poorly chosen outsole extend beyond immediate safety risks. The right choice contributes significantly to your daily health and ability to do your job effectively.

Reducing Daily Fatigue

The wrong boot can cause a sore back and aching legs by the end of a shift. A well-designed outsole provides the right balance of stability and shock absorption, reducing the cumulative strain on your feet, knees, and back.

This support system is crucial for maintaining energy and focus throughout long workdays, especially on hard surfaces like concrete.

Preventing Serious Injury

While a slip can be minor, it can also be catastrophic. The right outsole provides the reliable footing needed to prevent life-threatening falls from heights or into machinery.

Knowing you are properly equipped for your environment provides peace of mind, allowing you to concentrate fully on the task at hand.

Enhancing Job Performance

Comfort and safety directly influence your efficiency. When you aren't distracted by foot pain or worried about your stability, you can perform your duties more effectively and confidently.

As seen with law enforcement officers or construction workers, reliable footwear is essential for handling the unpredictable demands of a physically intensive job.

Understanding the Trade-offs

No single outsole is perfect for every situation. Choosing the right one involves understanding the key trade-offs between different designs and materials.

Softer vs. Harder Compounds

Softer rubber compounds offer superior grip, especially on smooth or wet surfaces, but they tend to wear down more quickly.

Harder, denser compounds provide excellent durability and longevity but may offer less traction on slick indoor floors.

Aggressive vs. Low-Profile Treads

Deep, widely spaced lugs are ideal for shedding mud and gripping uneven outdoor terrain. However, on flat surfaces, they can feel unstable and collect debris.

Conversely, a lower-profile tread with more surface contact is perfect for indoor environments but would offer insufficient grip on a construction site.

Making the Right Choice for Your Environment

Your specific work environment is the ultimate guide. Use these points to narrow down your selection based on your primary needs.

- If your primary focus is working on smooth, oily, or wet surfaces (e.g., auto shops, kitchens): Prioritize a slip- and oil-resistant outsole with a high-contact, shallow tread pattern designed to channel away liquids.

- If your primary focus is on uneven outdoor terrain (e.g., construction, logging, landscaping): Look for a durable outsole made from a hard rubber compound with deep, aggressive lugs for maximum traction.

- If your primary focus is exposure to specific hazards (e.g., electricians, welders, roofers): Ensure the outsole is explicitly rated for your risk, whether it's Electrical Hazard (EH), heat resistance, or puncture resistance.

Investing in the right outsole is a direct investment in your personal safety and professional capability.

Summary Table:

| Key Outsole Function | Why It Matters | Ideal For |

|---|---|---|

| Traction & Slip Resistance | Prevents slips and falls, the most common workplace accidents. | Oily floors, wet surfaces, smooth indoor environments. |

| Hazard Protection (EH, Puncture) | Shields feet from electrical shock, punctures, and extreme heat. | Electricians, construction sites, manufacturing plants. |

| Durability & Longevity | Extends boot life and ensures consistent performance. | Rugged outdoor terrain, high-abrasion environments. |

| Fatigue Reduction | Provides shock absorption and stability for long shifts. | Workers on hard surfaces like concrete. |

Ready to equip your workforce with the perfect work boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance safety footwear for distributors, brand owners, and bulk clients. Our expertise ensures every pair is built with the right outsole for your specific job site demands—enhancing safety, comfort, and durability.

Contact our team today for a customized solution and discover the 3515 difference.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- Why is comfort important in work boots? The Critical Link Between Comfort and Safety

- How do work boots differ from cowboy boots? Choosing the Right Footwear for Your Job

- Why is a melt-resistant sole important for wildland fire boots? Essential for Firefighter Safety & Traction

- How should composite toe boots be cared for to ensure longevity? Extend Boot Life with Simple Steps

- What maintenance practices extend the lifespan of work boots? A Proactive Care System for Maximum Durability

- What are the key parts of a work boot? A Guide to Safety, Comfort & Durability

- Why is fire-resistant stitching important in wildland firefighter boots? It's the Unseen Skeleton of Safety

- What innovative technologies enhance comfort in work boots? Achieve All-Day Comfort and Performance