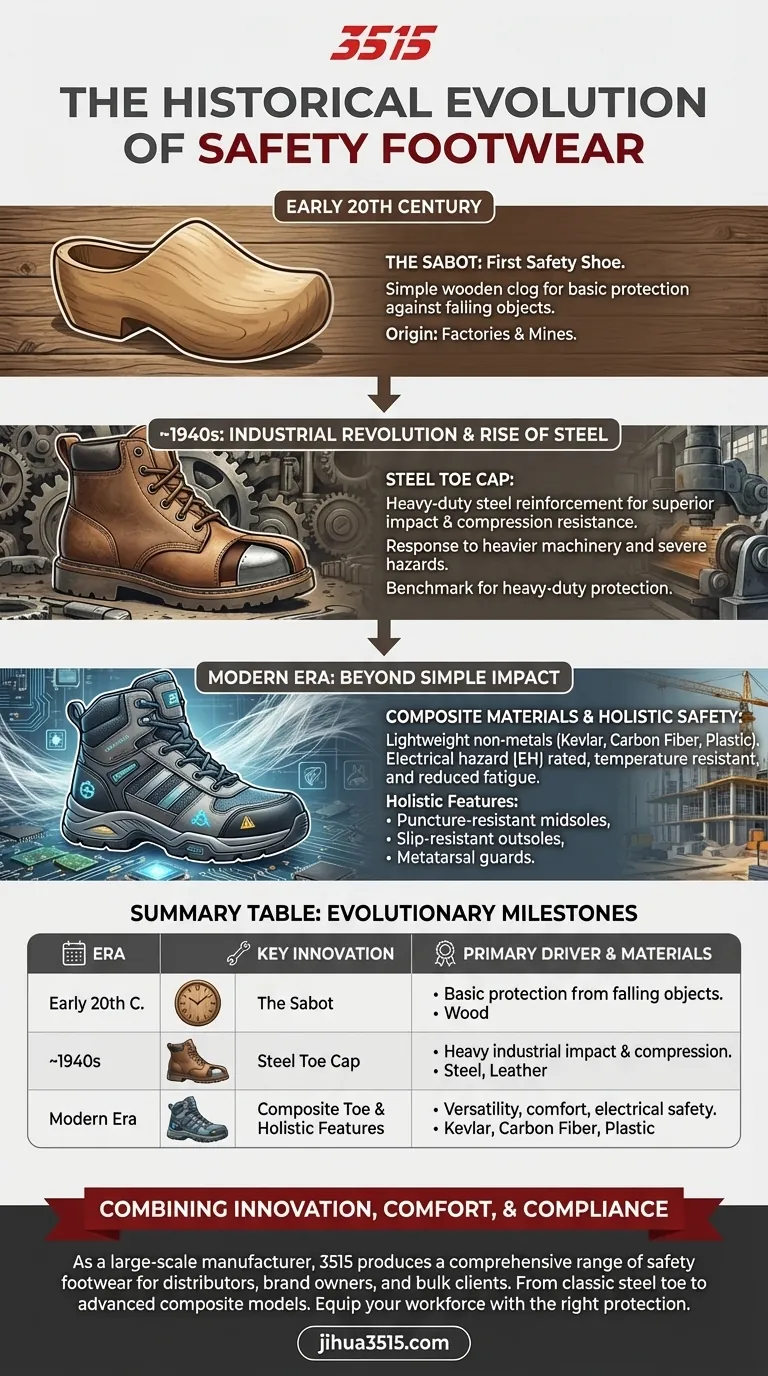

Historically, safety footwear emerged in the early 20th century as industrialization exposed workers to new and severe workplace hazards. The first widely recognized form of safety footwear was the sabot, a simple wooden clog designed to protect feet from falling objects in environments like factories and mines. This marked the beginning of a century-long evolution driven by the need to counter increasingly complex workplace dangers.

The history of safety footwear is a direct reflection of industrial progress itself. Each major innovation—from wood to steel to modern composites—was developed in response to new dangers and a growing understanding of worker protection.

The Dawn of Worker Protection

The concept of protecting workers' feet is not new, but its formalization is a product of the industrial age. Before specialized footwear, injuries were a common and accepted risk of manual labor.

The Sabot: The First Safety Shoe

The sabot, a clog made from a hollowed-out block of wood, was one of the earliest forms of protective footwear. It originated in Europe and was widely used by agricultural and factory workers.

Its primary benefit was its simple, rigid construction. The wood provided a solid barrier against crushing injuries from heavy items and protected feet from sharp objects on the floor.

The Industrial Revolution and the Rise of Steel

As industries scaled up with heavier machinery and more complex processes, the limitations of wood became apparent. A stronger, more durable solution was needed to protect against the severe impact hazards of modern factories, foundries, and construction sites.

The Advent of the Steel Toe Cap

The steel toe cap was the definitive answer to this challenge. Developed around the 1940s, this innovation involved inserting a heavy-duty steel reinforcement into the toe of a standard leather work boot.

This design offered vastly superior impact and compression resistance compared to wood. It effectively created a shield for the most vulnerable part of the foot, dramatically reducing the frequency of serious injuries.

Formalization and Standards

The introduction of the steel toe boot coincided with the rise of formal occupational safety regulations. Governments and industries began establishing standards that mandated the use of protective footwear, with the steel toe boot becoming the benchmark for heavy-duty protection.

The Modern Era: Beyond Simple Impact

While steel was a monumental leap forward, it had inherent limitations. Its weight caused fatigue, it conducted heat and cold, and it posed a problem in work environments with electrical hazards or metal detectors.

Enter Composite Materials

More recent developments have led to the creation of composite toe caps. These are made from non-metal materials like Kevlar, carbon fiber, fiberglass, or plastic.

Composite materials offer a lightweight alternative to steel while still meeting anufacturing safety standards. They do not conduct electricity, making them ideal for electricians and engineers, and they are not subject to temperature extremes.

A Holistic Approach to Safety

Modern safety footwear has evolved far beyond just the toe cap. Today, boots are designed with a complete system of protective features, including:

- Puncture-resistant midsoles to protect against nails.

- Slip-resistant outsoles for traction on slick surfaces.

- Electrical Hazard (EH) ratings to insulate against shock.

- Metatarsal guards to protect the top of the foot.

Understanding the Evolutionary Drivers

Each step in the history of safety footwear was a direct response to a specific need. Understanding these drivers helps clarify why we have the options we do today.

Hazard-Driven Innovation

The evolution from wood to steel to composites was not arbitrary. Wood was sufficient for basic protection, steel was required for heavy industrial impact, and composites were developed to address the secondary needs of weight, conductivity, and comfort.

The Pursuit of Comfort and Compliance

A critical driver of modern innovation is user adoption. An uncomfortable safety boot is less likely to be worn correctly, defeating its purpose. The development of lighter materials and more ergonomic designs is directly aimed at increasing worker comfort and ensuring consistent compliance.

What This History Means for Today's Choices

Understanding the historical context of safety footwear allows you to make a more informed decision based on the specific hazards of your work environment.

- If your primary focus is maximum impact and compression resistance: Steel toe boots remain the industry standard for the heaviest and most dangerous work, reflecting their origin in heavy industry.

- If your primary focus is working around electricity, extreme temperatures, or reducing fatigue: Composite toe footwear is the modern evolution, designed for versatility and comfort in a wider range of technical environments.

- If your primary focus is full-foot protection: Look beyond the toe cap to modern features like puncture-resistant soles and metatarsal guards, which represent the holistic safety approach of the 21st century.

Modern safety footwear is the result of over a century of innovation, offering a specialized solution for nearly any workplace hazard imaginable.

Summary Table:

| Era | Key Innovation | Primary Driver | Key Materials |

|---|---|---|---|

| Early 20th Century | The Sabot | Basic protection from falling objects | Wood |

| ~1940s | Steel Toe Cap | Heavy industrial impact & compression | Steel, Leather |

| Modern Era | Composite Toe & Holistic Features | Versatility, comfort, electrical safety | Kevlar, Carbon Fiber, Plastic |

Need modern safety footwear that combines a century of innovation with comfort and compliance?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, from classic steel toe to advanced composite models with puncture-resistant soles and EH ratings.

Let us help you equip your workforce with the right protection for any hazard. Contact our experts today to discuss your specific needs and explore our catalog.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- Why do my feet hurt in safety shoes? How to Fix the Safety vs. Comfort Conflict

- What toe options are available for oil-resistant safety boots? Find the Right Fit for Your Job

- How do industrial-grade anti-fatigue mats complement occupational safety shoes in a factory environment? Boost Comfort

- Why are mesh materials preferred for safety shoes in hot and humid conditions? Enhance Worker Comfort & Focus

- What are the safety shoe standards in Asia? Navigate Country-by-Country Compliance

- What are the benefits of using waterproof safety shoes during mining road maintenance and dust suppression activities?

- Why are insulated protective shoes necessary? Essential Protection Against High-Voltage and Electrical Leakage Risks

- Why is rotating between two pairs of safety shoes beneficial? Extend Lifespan and Boost Foot Health