At its core, a Goodyear welt is a superior method of shoe construction that uses a dedicated strip of leather—the welt—to stitch the shoe's upper and sole together. This technique, developed in the late 1800s, creates an exceptionally durable, water-resistant, and repairable shoe by avoiding a direct connection between the upper and the final outsole. It stands in contrast to simpler methods like Blake stitching, which sews the upper directly to the sole, or cemented construction, which relies on industrial adhesives.

Choosing a Goodyear welted shoe is an investment in longevity. The construction method is designed not just to last, but to be rebuilt, allowing a high-quality upper to outlive its original sole many times over.

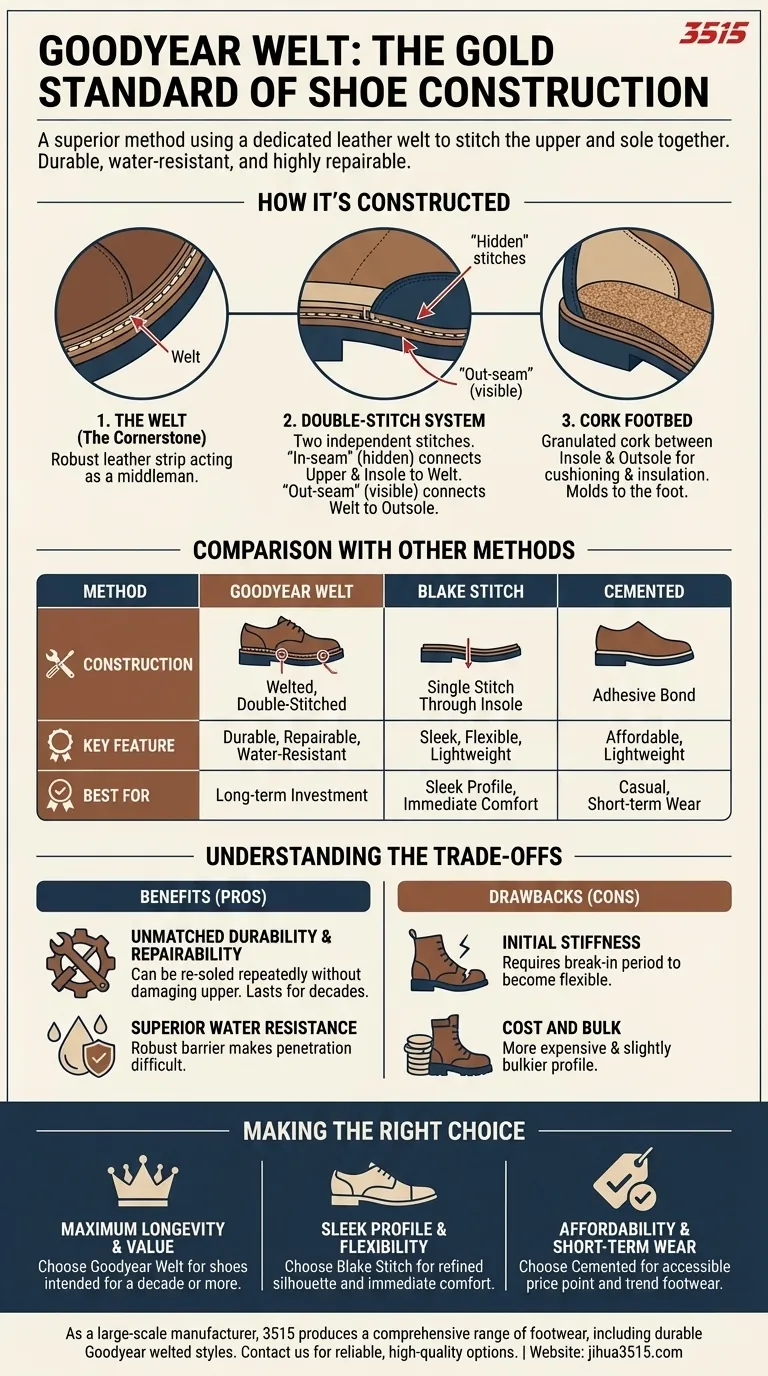

How a Goodyear Welt Is Constructed

To understand the value of a Goodyear welt, you must first understand its distinct, multi-step process. It is a more complex and labor-intensive method than modern alternatives, which is central to its durability.

The Role of the Welt

The welt is the cornerstone of this entire method. It is a robust strip of leather that runs along the perimeter of the shoe's outsole.

This component acts as a middleman. The shoe’s upper is stitched to the welt, and the welt is then separately stitched to the outsole.

The Double-Stitch System

This separation creates two independent and strong stitches. The first stitch, often called the in-seam, is hidden from view and attaches the upper, lining, and insole to the welt.

The second stitch, the out-seam, is visible on the bottom of the shoe and attaches the welt to the outsole. This design means the outsole can be removed and replaced by a cobbler without ever disturbing the structure of the upper.

The Cork Footbed

Between the insole and the outsole, a cavity is created which is filled with a layer of granulated cork.

This cork footbed provides excellent cushioning and insulation. Over time, it molds to the unique shape of your foot, creating a custom-like fit that improves with wear.

Goodyear Welt vs. Other Common Methods

The benefits of the Goodyear welt become clearest when compared to the two other dominant construction methods. Each serves a different purpose and price point.

Comparison with Blake Stitch

In a Blake stitch construction, a single stitch runs directly from the inside of the shoe, through the insole and upper, and into the outsole.

This creates a more flexible, sleeker, and lighter shoe. However, it compromises water resistance as moisture can wick up the thread, and re-soling is more complex and can damage the insole.

Comparison with Cemented Construction

Cemented construction is the most common method in modern footwear. The outsole is simply attached to the upper using a strong, industrial adhesive.

This method is fast, inexpensive, and allows for lightweight designs. The trade-off is durability; the bond will eventually fail, and the shoes are almost never designed to be re-soled.

Understanding the Trade-offs

While the Goodyear welt is considered a gold standard, it is not without its compromises. Understanding these trade-offs is key to making an informed decision.

The Benefit: Unmatched Durability & Repairability

The ability to re-sole the shoe repeatedly is the primary advantage. Because the outsole is stitched to the welt and not the upper, a worn-out sole can be replaced without compromising the shoe's core structure.

This means a single pair of high-quality shoes can last for decades, not just years.

The Benefit: Superior Water Resistance

The welt creates a more robust barrier between the ground and your foot. The layered construction and external stitching make it significantly more difficult for water to penetrate the shoe compared to a Blake stitch.

The Drawback: Initial Stiffness

Goodyear welted shoes are notoriously stiff when new. The robust construction and cork footbed require a significant break-in period to become flexible and conform to your foot.

The Drawback: Cost and Bulk

This method requires more materials and skilled labor, making the shoes more expensive upfront. The construction also results in a slightly bulkier and less sleek profile than Blake-stitched or cemented shoes.

Making the Right Choice for Your Goal

Your ideal shoe construction method depends entirely on what you value most.

- If your primary focus is maximum longevity and long-term value: The Goodyear welt is the definitive choice for footwear you intend to keep and maintain for a decade or more.

- If your primary focus is a sleek profile and immediate out-of-the-box flexibility: A Blake-stitched shoe offers a more refined silhouette and requires less break-in time.

- If your primary focus is affordability and casual, short-term wear: Cemented construction provides the most accessible price point for trend-focused or occasional-use footwear.

Ultimately, choosing a Goodyear welted shoe is a conscious decision to invest in enduring craftsmanship over disposable convenience.

Summary Table:

| Construction Method | Key Feature | Best For |

|---|---|---|

| Goodyear Welt | Durable, repairable, water-resistant | Long-term investment, durability |

| Blake Stitch | Sleek, flexible, lightweight | Sleek profile, immediate comfort |

| Cemented | Affordable, lightweight, fast production | Affordability, casual/short-term wear |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including durable Goodyear welted styles built to last. If you are looking for reliable, high-quality footwear that offers long-term value to your customers, contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort

- How do rubber and TPR soles compare in terms of water resistance? A Guide to Grip and Performance

- Which type of sole is better for hard surfaces? Rubber Soles for Superior Comfort & Durability