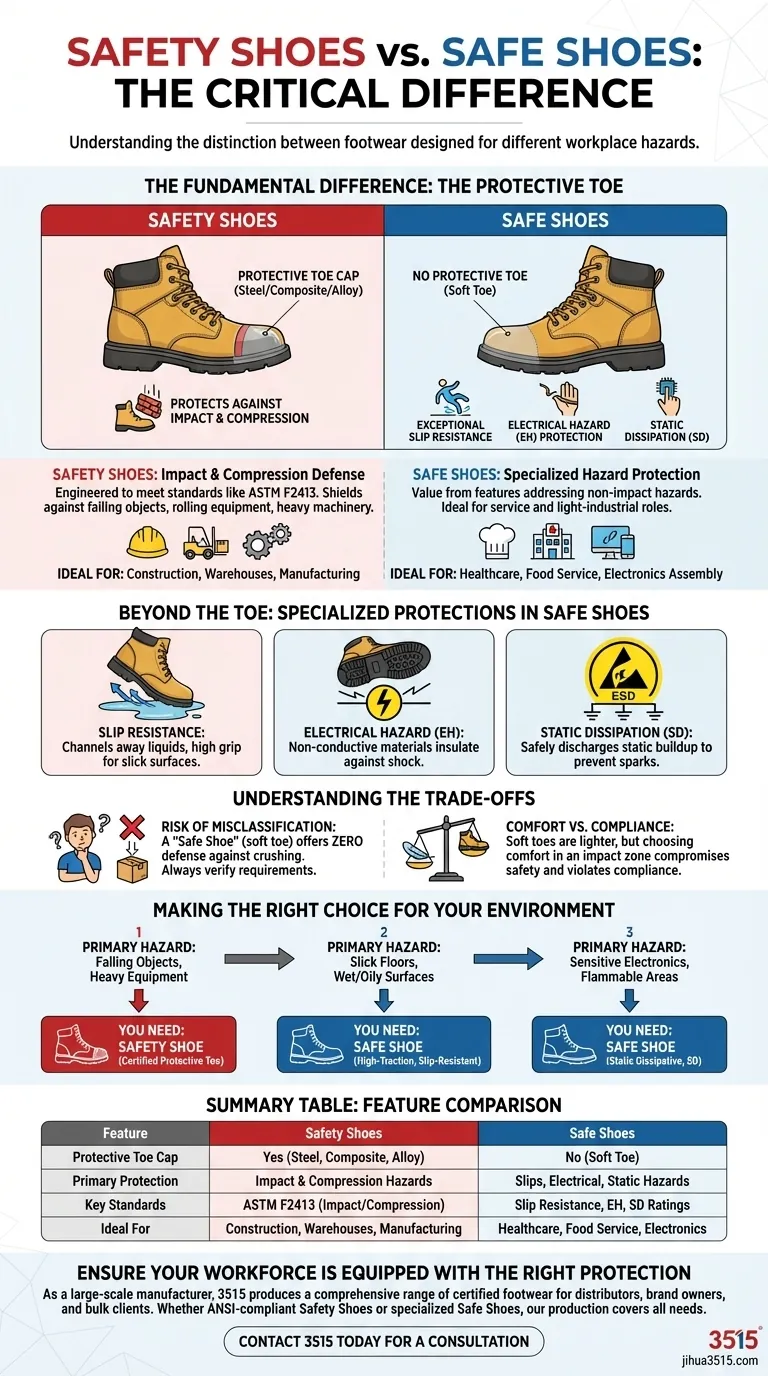

The fundamental difference is the presence of a protective toe cap. "Safety Shoes" are specifically engineered with a reinforced toe—typically made of steel, composite, or alloy—to protect against impact and compression hazards. In contrast, "Safe Shoes" do not have this protective toe but are designed with other critical safety features, such as exceptional slip resistance or static dissipation.

The distinction is not merely semantic; it's a critical classification based on the type of hazard the footwear is designed to mitigate. A "Safety Shoe" protects your toes from being crushed, while a "Safe Shoe" protects you from other dangers like slips or electrostatic discharge.

The Defining Feature: The Protective Toe

The presence or absence of a reinforced safety toe is the non-negotiable dividing line between these two categories of footwear. This single component dictates the shoe's primary protective function.

What are 'Safety Shoes'?

Safety Shoes are built to meet specific industry standards (like ASTM F2413 in the US) for impact and compression resistance.

Their core purpose is to shield the foot from falling objects, rolling equipment, or heavy machinery. This makes them essential in environments like construction sites, warehouses, and manufacturing plants.

The reinforced toe is the defining characteristic that legally and functionally qualifies them as "safety toe" footwear.

What are 'Safe Shoes'?

Safe Shoes, often called "soft toe" work shoes, lack this protective toe cap.

Their value comes from other specialized safety technologies built into the shoe. They address hazards that are unrelated to impact, making them ideal for many service and light-industrial roles.

Think of them as professional-grade footwear engineered for a specific environmental risk other than crushing.

Beyond the Toe: Specialized Protections

If a "Safe Shoe" doesn't have a protective toe, what makes it safe? The safety comes from features targeted at specific, common workplace hazards.

Slip Resistance

This is the most common feature in "Safe Shoes." Specialized outsole compounds and tread patterns are designed to channel away liquids and maintain a strong grip on wet, oily, or otherwise slick surfaces.

This is critical for workers in restaurants, healthcare facilities, and food processing, where slips and falls are the primary risk.

Electrical Hazard (EH)

Some "Safe Shoes" are rated for Electrical Hazard protection. They are built with non-conductive materials to insulate the wearer from the ground, reducing the risk of electric shock from accidental contact with live circuits.

Static Dissipation (SD)

In environments with sensitive electronics or flammable materials, static electricity can be a significant danger. SD footwear is designed to safely discharge static buildup from your body to the floor.

This prevents a spark that could damage a component or ignite a vapor, making these shoes vital in electronics assembly or certain chemical handling areas.

Understanding the Trade-offs

Choosing the wrong type of shoe based on a misunderstanding of these terms can have serious consequences. A shoe can be "safe" for one job but completely inadequate and dangerous for another.

The Risk of Misclassification

The most critical mistake is assuming a "Safe Shoe" provides toe protection. A slip-resistant shoe offers zero defense against a falling pallet or a rolling cart.

Always verify if your workplace mandates a safety toe. If it does, only a true "Safety Shoe" is compliant and will provide the necessary protection.

Comfort vs. Compliance

"Safe Shoes" are generally lighter and more flexible than their safety-toed counterparts, which can be a factor in jobs that require constant walking or standing.

However, choosing a soft-toe shoe for comfort in an environment that has a clear impact hazard is a dangerous trade-off that compromises personal safety and violates compliance standards.

Making the Right Choice for Your Environment

Your specific workplace hazards must be the sole factor in your decision. Assess your environment to determine the primary risks you face daily.

- If your primary focus is protection from falling objects or heavy equipment: You unequivocally need a "Safety Shoe" with a certified protective toe.

- If your primary focus is preventing falls on slick floors: You need a "Safe Shoe" with a high-traction, slip-resistant outsole.

- If your primary focus is working with sensitive electronics or in flammable areas: You need a "Safe Shoe" with Static Dissipative (SD) properties.

Ultimately, understanding this distinction empowers you to select the correct Personal Protective Equipment for your specific role.

Summary Table:

| Feature | Safety Shoes | Safe Shoes |

|---|---|---|

| Protective Toe Cap | Yes (Steel, Composite, Alloy) | No (Soft Toe) |

| Primary Protection | Impact & Compression Hazards | Slips, Electrical, Static Hazards |

| Key Standards | ASTM F2413 (Impact/Compression) | Slip Resistance, EH, SD Ratings |

| Ideal For | Construction, Warehouses, Manufacturing | Healthcare, Food Service, Electronics |

Ensure Your Workforce is Equipped with the Right Protection

As a large-scale manufacturer, 3515 produces a comprehensive range of certified footwear for distributors, brand owners, and bulk clients. Whether your environment demands ANSI-compliant Safety Shoes with protective toes or specialized Safe Shoes with superior slip resistance or static dissipation, our production capabilities cover all types of safety and work boots.

Let us help you make the right choice for your team's safety and compliance needs.

Contact 3515 today for a consultation to discuss your specific requirements and explore our full catalog.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- How do safety shoes with high-performance slip-resistant outsoles prevent injuries? Enhance Grip in Adverse Weather

- What are the different levels of impact protection provided by safety toe boxes? A Guide to I/75, I/50 & I/30 Ratings

- How have synthetic materials impacted safety shoe design? Achieve Specialized Protection & All-Day Comfort

- What role does professional footwear play in reducing ground reaction forces? Enhance Postpartum Cardio Safety

- What functions do high-sensitivity flexible pressure sensor (FSR) insoles provide in safety footwear testing? (2024 Guide)

- What are the pros and cons of composite safety toes? Weighing Weight vs. Ultimate Protection

- How does DAI assist in evaluating footwear support? Use Biomechanics to Optimize Safety & Tactical Shoe Design

- What materials are used in composite toe boots? Discover the Non-Metallic Safety Advantage