To properly dry your boots after waterproofing, the single best method is to let them air dry slowly and naturally. Place them in a well-ventilated room with low humidity at a consistent, average temperature, keeping them away from any direct heat sources or sunlight.

The goal of drying is not speed, but preservation. Rushing the process with high heat can permanently damage your boot's materials and adhesives, negating the waterproofing effort and shortening the life of your footwear.

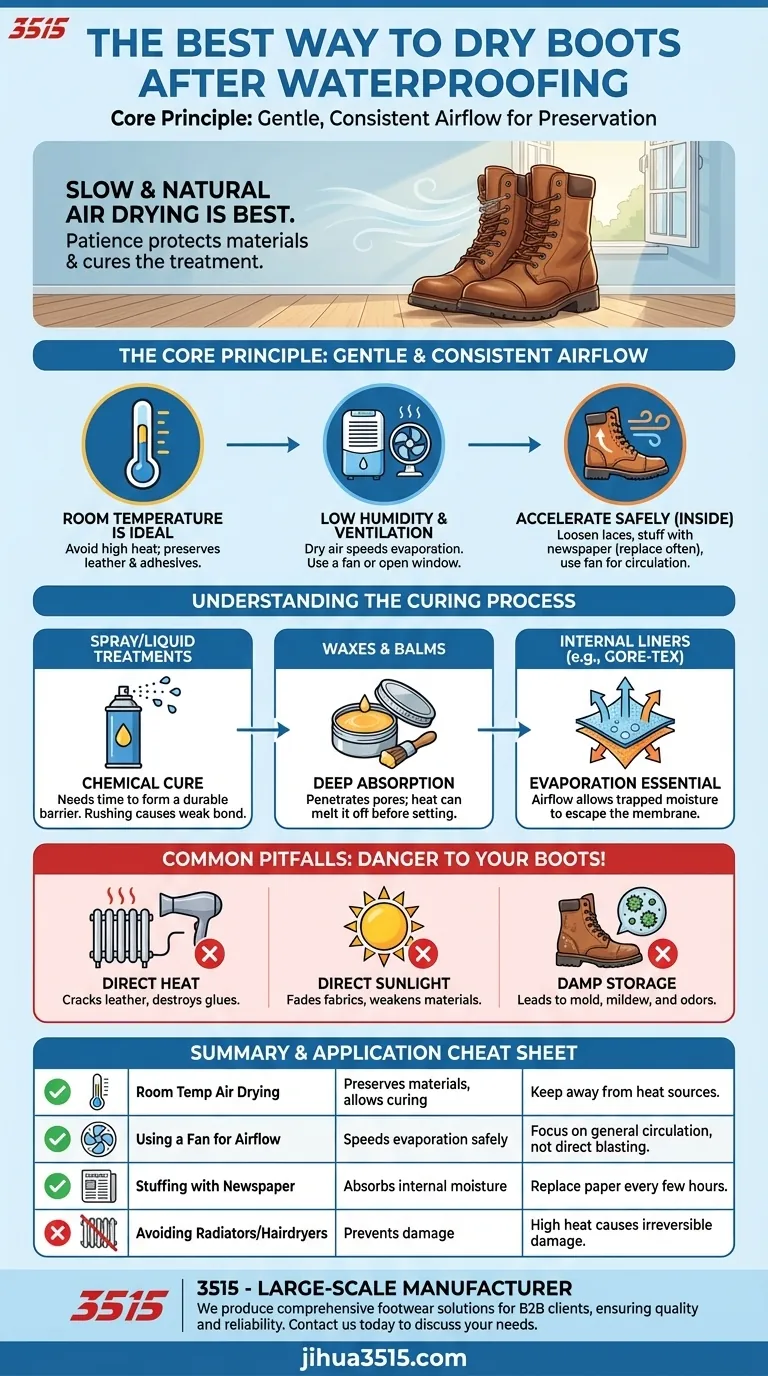

The Core Principle: Gentle and Consistent Airflow

Properly drying your boots is as crucial as the waterproofing application itself. The entire process relies on allowing moisture to evaporate and the waterproofing treatment to cure correctly without stressing the boot's materials.

Why Room Temperature is Ideal

Your boots are constructed from materials—leather, rubber, synthetic fabrics, and adhesives—that are designed to be stable at normal temperatures.

Exposing them to high heat can cause leather to shrink, crack, and become brittle. It can also weaken the glues and cements used to bond the sole to the upper, leading to delamination.

The Importance of Low Humidity

High humidity in the air slows down evaporation, prolonging the drying time. A dry, well-ventilated space is your greatest asset.

You can achieve this by placing the boots near an open window (out of direct sun), in a room with a dehumidifier, or simply near a fan to keep the air moving.

How to Accelerate Drying Safely

If you need to speed up the process, focus on removing moisture from the inside of the boot.

Loosen the laces and open the boot up as much as possible. You can then stuff them with balled-up newspaper or paper towels, which will absorb internal moisture. Replace the paper every few hours. A small fan directed at the boots can also significantly improve air circulation.

Understanding the Curing Process

Drying isn't just about removing water; it's about allowing the waterproofing product to properly set and bond with the boot material.

For Sprays and Liquid Treatments

Waterproofing sprays, especially those for suede or synthetic fabrics, need time to cure. This chemical process allows the protective barrier to form and adhere to the fibers.

Rushing this with heat can cause an incomplete cure, resulting in a weak, ineffective barrier that wears off quickly.

For Waxes and Balms

Waxes and balms applied to leather boots work by penetrating the pores of the material. A slow drying process allows for maximum absorption.

This ensures the leather is conditioned deeply while the wax provides a durable, water-repellent surface. Heat can cause the wax to melt and run off before it has fully set.

The Role of Internal Liners

Many modern boots feature a waterproof, breathable membrane (like GORE-TEX). While this liner keeps water out, it can also trap moisture inside.

Proper air drying with good ventilation is essential to allow this trapped moisture to evaporate out through the membrane, preventing mildew and odors.

Common Pitfalls That Damage Your Boots

Avoiding shortcuts is the key to preserving your investment. Certain common "hacks" for drying boots can cause irreversible damage.

The Danger of Direct Heat

Never place your boots near a radiator, fireplace, wood stove, or use a hairdryer on them. The intense, direct heat will destroy leather and compromise the adhesives holding your boots together.

Why Sunlight Is a Problem

While it may seem natural, drying boots in direct sunlight is also damaging. UV rays can fade and weaken synthetic fabrics, while the heat has the same damaging effect on leather as any other direct heat source.

The Mistake of Storing While Damp

Ensuring your boots are 100% dry before storing them is critical. Storing even slightly damp boots can lead to the growth of mold and mildew, which can ruin the materials and create a persistent odor.

How to Apply This to Your Boots

Your approach should be consistent, but you can tailor it slightly based on the waterproofing method you've used.

- If you have just applied a wax or balm to leather boots: Let them sit for at least 24 hours at room temperature to ensure the treatment has fully penetrated and cured.

- If you have treated suede or synthetic boots with a spray: Place them in an area with maximum airflow, like near a fan, to help the chemical carriers evaporate and leave the waterproof barrier behind.

- If your primary goal is drying boots with an internal liner: Focus on interior moisture by opening them fully and stuffing them with newspaper to wick moisture away from the inside.

Properly drying your waterproofed boots ensures your gear is ready and reliable for your next adventure.

Summary Table:

| Drying Method | Why It's Recommended | Key Consideration |

|---|---|---|

| Room Temperature Air Drying | Preserves materials (leather, adhesives); allows proper curing. | Keep away from direct heat sources and sunlight. |

| Using a Fan for Airflow | Speeds evaporation safely without high heat. | Focus on general air circulation, not direct blasting. |

| Stuffing with Newspaper | Absorbs internal moisture effectively. | Replace paper every few hours for best results. |

| Avoiding Radiators/Hairdryers | Prevents leather cracking and adhesive failure. | High heat causes irreversible damage. |

Need durable, high-performance boots that are built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring quality and reliability for your customers.

Contact us today to discuss your footwear needs and discover how we can provide the durable solutions your business requires.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What is the function of chemical cleaning agents for Bacterial Cellulose? Ensure High-Value Material Purity

- What key stages are involved in the circularity strategy for footwear manufacturing? Build a Closed-Loop Future

- Which kinetic indicators do force plates provide for footwear research? Key Metrics for Gait Database Construction

- How is an IMU motion capture system used to validate plantar pressure sensors? Mastering Kinematic Data Calibration

- What height are the jumps the rider plans to start with? Build a Strong Foundation with 2-Foot Jumps

- Why is the placement of a full set of reflective markers essential for human gait biomechanical models in footwear design?

- What role do therapeutic shoes with pressure-relieving insoles play in diabetic post-op recovery? Key Benefits Revealed

- How does digital plantar pressure analysis contribute to high-performance footwear? Master Science-Driven Design