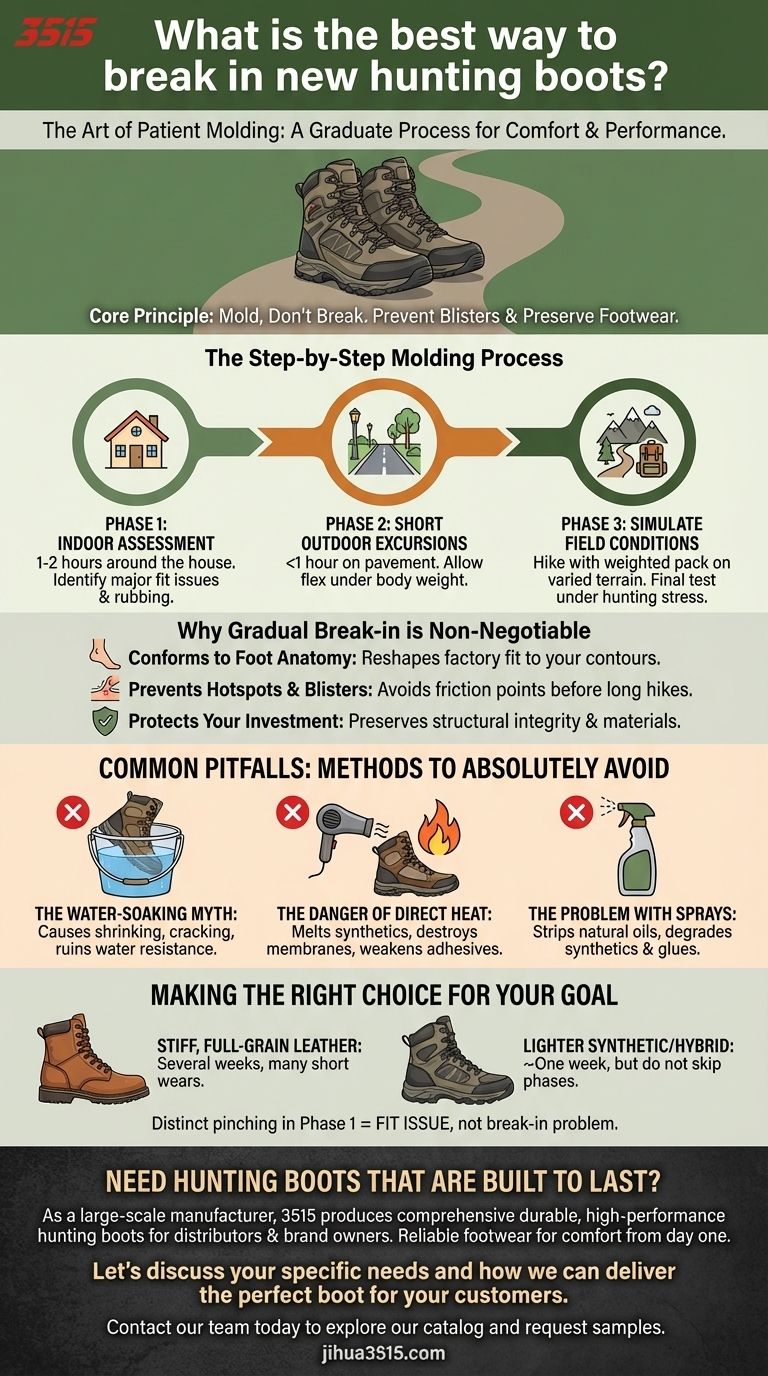

The best way to break in new hunting boots is through a patient, gradual process of wearing them in environments that slowly escalate to field conditions. This method allows the boot's materials to safely mold to the unique shape of your foot, preventing the blisters and discomfort that can ruin a hunt.

The core principle is not to "break" the boot, but to mold it. Hasty or aggressive methods risk damaging expensive boots and your feet, while a deliberate, multi-stage approach ensures a custom fit that delivers comfort and reliability when it matters most.

Why a Gradual Break-in is Non-Negotiable

A proper break-in period is an investment in comfort and performance. Rushing the process is the most common mistake a hunter can make with new footwear.

Conforming to Your Foot's Anatomy

New boots, particularly those made of stiff leather, have a generic factory shape. The heat and pressure from your foot during gradual wear slowly reshape the footbed and upper materials to match your specific contours.

Preventing Hotspots and Blisters

Walking for hours in stiff, ill-fitting boots creates friction points, or hotspots. If ignored, these quickly turn into debilitating blisters. A slow break-in identifies these potential problem areas long before you are miles from your vehicle.

Protecting Your Investment

Methods that use excessive water or heat can permanently damage the boot's materials. Leather can crack, adhesives can fail, and waterproof membranes can be compromised. A patient break-in preserves the boot's structural integrity and longevity.

The Step-by-Step Molding Process

This process is designed to take your boots from the box to field-ready without causing pain or damage. The timeline can range from one week for lighter synthetic boots to several weeks for stiff leather models.

Phase 1: The Indoor Assessment

Start by wearing your new boots around the house for just an hour or two at a time. This is the initial test for any major fit issues.

Walk around, go up and down stairs, and sit for a while. This low-impact environment lets you identify any immediate pinching or excessive rubbing.

Phase 2: Short Outdoor Excursions

Once the boots feel comfortable indoors, begin wearing them for short outings. Think walking the dog, running errands, or taking a walk around the neighborhood on pavement.

This introduces more dynamic movement and allows the boot to flex under your body weight on different surfaces. Keep these sessions under an hour to start, gradually increasing the duration.

Phase 3: Simulating Field Conditions

The final phase is to mimic the demands of a hunt. Find a local trail or park with varied terrain, including inclines and declines.

Start with short hikes and, critically, wear the same pack and approximate weight you plan to carry on your hunt. This is the ultimate test of the boot's fit, as the extra weight will alter how your foot sits and moves inside the boot.

Common Pitfalls: Methods to Absolutely Avoid

Several myths about breaking in boots persist. These "shortcuts" are dangerous to both your feet and your footwear.

The Water-Soaking Myth

Submerging boots in water or wearing wet socks is a common but terrible piece of advice. This process can cause leather to shrink unevenly and crack as it dries, ruining its supportive structure and water resistance. It also dramatically increases your risk of blisters.

The Danger of Direct Heat

Using a hair dryer or placing boots near a fire to soften them can be catastrophic. Excessive heat can melt synthetic components, destroy waterproof membranes, and cause adhesives holding the sole together to fail.

The Problem with Sprays

Spraying boots with alcohol or other concoctions can strip the natural oils from leather, leading to premature aging and cracking. These chemicals can also degrade synthetic fabrics and glues.

Making the Right Choice for Your Goal

Your approach should be tailored to your specific boot and your primary objective: reliability in the field.

- If your boots are stiff, full-grain leather: Plan for a longer break-in period of several weeks, focusing on many short wears to slowly soften the material without causing damage.

- If your boots are a lighter synthetic/hybrid: The break-in period may only be a week, but do not skip the phases of progressing from indoors to weighted hikes.

- If you feel any distinct pinching or sharp pain in Phase 1: This is a sign of a fundamental fit issue, not a break-in problem; you should stop and consider exchanging the boots for a different size or model.

Properly preparing your boots ensures they become a trusted and comfortable tool, not a painful liability on your hunt.

Summary Table:

| Phase | Activity | Goal |

|---|---|---|

| 1: Indoor Assessment | Wear boots around the house for 1-2 hours. | Identify major fit issues and initial rubbing. |

| 2: Short Outdoor Excursions | Walk on pavement for short outings (<1 hour). | Allow boots to flex under body weight. |

| 3: Simulate Field Conditions | Hike with a weighted pack on varied terrain. | Test final fit under realistic hunting stress. |

Need Hunting Boots That Are Built to Last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, high-performance hunting boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get reliable footwear designed for comfort in the field from day one.

Let's discuss your specific needs and how we can deliver the perfect boot for your customers. Contact our team today to explore our catalog and request samples.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

- Durable Spiked Camouflage Boots Wholesale & Factory Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

People Also Ask

- How do hunting boot designs address varying terrain challenges? The Ultimate Guide to Matching Boots to Your Hunt

- Why are high-quality materials important for men's country boots? Invest in Durability & Long-Term Value

- Which technical features are essential for professional outdoor shoes to prevent falls on slippery terrains or rugged infrastructure? Master Stability & Traction for Ultimate Safety.

- Can synthetic material boots like the Crispi Idaho be resoled? Yes, and here's how to extend their life.

- What materials are commonly used to make waterproof shoes? A Guide to Rubber, Gore-Tex & Treated Leather

- What are the key features of hunting boots? Master Your Terrain with the Right Footwear

- What additional features can premium motorcycle boots offer? Unlock Ultimate Comfort & Safety

- What are waterproof shoes and where are they most effectively used? A Guide to Staying Dry