The primary benefit of synthetic military boots is their combination of being lightweight, quick-drying, and requiring a much shorter break-in period than traditional leather. These characteristics make them highly effective for modern missions where mobility and readiness in varied environmental conditions are paramount.

Synthetic boots trade the long-term, rugged durability of high-quality leather for immediate, out-of-the-box performance. The choice between them depends entirely on the operational environment and mission requirements.

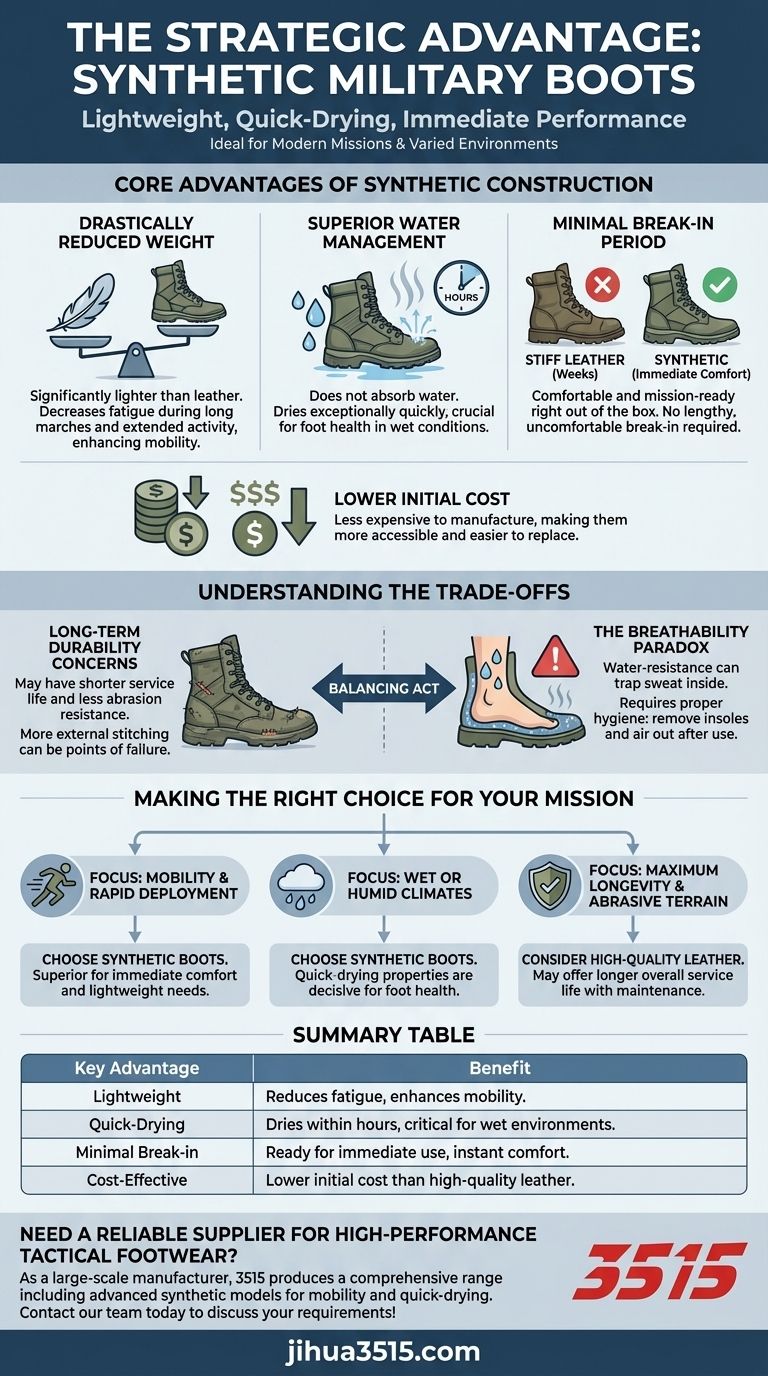

The Core Advantages of Synthetic Construction

Modern military boots increasingly use synthetic materials like nylon and polyester for clear, performance-oriented reasons. They solve many of the historical challenges associated with traditional all-leather footwear.

Drastically Reduced Weight

Synthetic materials are inherently lighter than leather. This reduction in weight translates directly to less fatigue for the wearer over long marches or extended periods of activity.

Superior Water Management

Perhaps the most significant advantage is how synthetics handle moisture. They do not absorb water like leather and dry exceptionally quickly, often within hours. This is critical for maintaining foot health and comfort in wet environments.

Minimal Break-in Period

Unlike stiff leather boots that can require weeks of uncomfortable wear to conform to your feet, synthetic boots are often comfortable and ready for demanding use almost immediately.

Lower Initial Cost

Generally, boots made from synthetic materials are less expensive to manufacture than those made from high-quality leather. This makes them more accessible and easier to replace.

Understanding the Trade-offs

While the benefits are compelling, it's crucial to understand that synthetic materials introduce a different set of compromises compared to traditional options.

Long-Term Durability Concerns

Synthetics may not possess the same long-term abrasion resistance as high-quality leather. The use of more external stitching on synthetic boots can also create potential points of failure over time, possibly leading to a shorter service life.

The Breathability Paradox

Many synthetic boots are water-resistant or waterproof, which is excellent for keeping external moisture out. However, this can sometimes lead to inferior breathability, trapping sweat and moisture inside the boot.

Proper foot hygiene becomes critical. To combat this, insoles must be removed and the boots fully unlaced to allow them to air out and dry internally after use.

Making the Right Choice for Your Mission

Selecting the right boot is a tactical decision. There is no single "best" material; there is only the right material for the specific context and goal.

- If your primary focus is mobility and rapid deployment: The lightweight nature and immediate comfort of synthetic boots are the superior choice.

- If your primary focus is operations in wet or humid climates: The quick-drying properties of synthetics provide a decisive advantage for foot health and morale.

- If your primary focus is maximum longevity in dry, abrasive terrain: A high-quality, well-maintained leather boot may offer a longer overall service life.

Ultimately, choosing the right boot is about matching the material's inherent strengths to the demands of your environment.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Lightweight | Reduces fatigue, enhances mobility for long marches and rapid deployment. |

| Quick-Drying | Dries within hours, crucial for foot health in wet/humid environments. |

| Minimal Break-in | Ready for immediate use, providing comfort right out of the box. |

| Cost-Effective | Lower initial cost compared to high-quality leather boots. |

Need a reliable supplier for high-performance tactical footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of military and tactical boots, including advanced synthetic models designed for superior mobility and quick-drying performance.

Let us help you equip your personnel with the right gear for their mission. Contact our team today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

People Also Ask

- How is the compatibility of polymer materials demonstrated in smart footwear? Enhancing Tactical & Training Performance

- What is the historical background of combat boots and jump boots? Discover Their Purpose-Built Evolution

- What are the advantages of using military boots for hiking? Durability & Support for Rugged Terrain

- What factors should be considered when choosing military camouflage boots? Prioritize Mission Performance Over Style

- What features enhance insulation and waterproofing in military boots? Key Technologies for Mission Success

- Why is the breaking-in period important for military boots? Ensure Mission Readiness & Prevent Injury

- How should the leather of these boots be maintained? A 3-Step Guide to Lasting Durability

- How can desert boots be styled for smart casual occasions? Achieve Effortlessly Polished Style