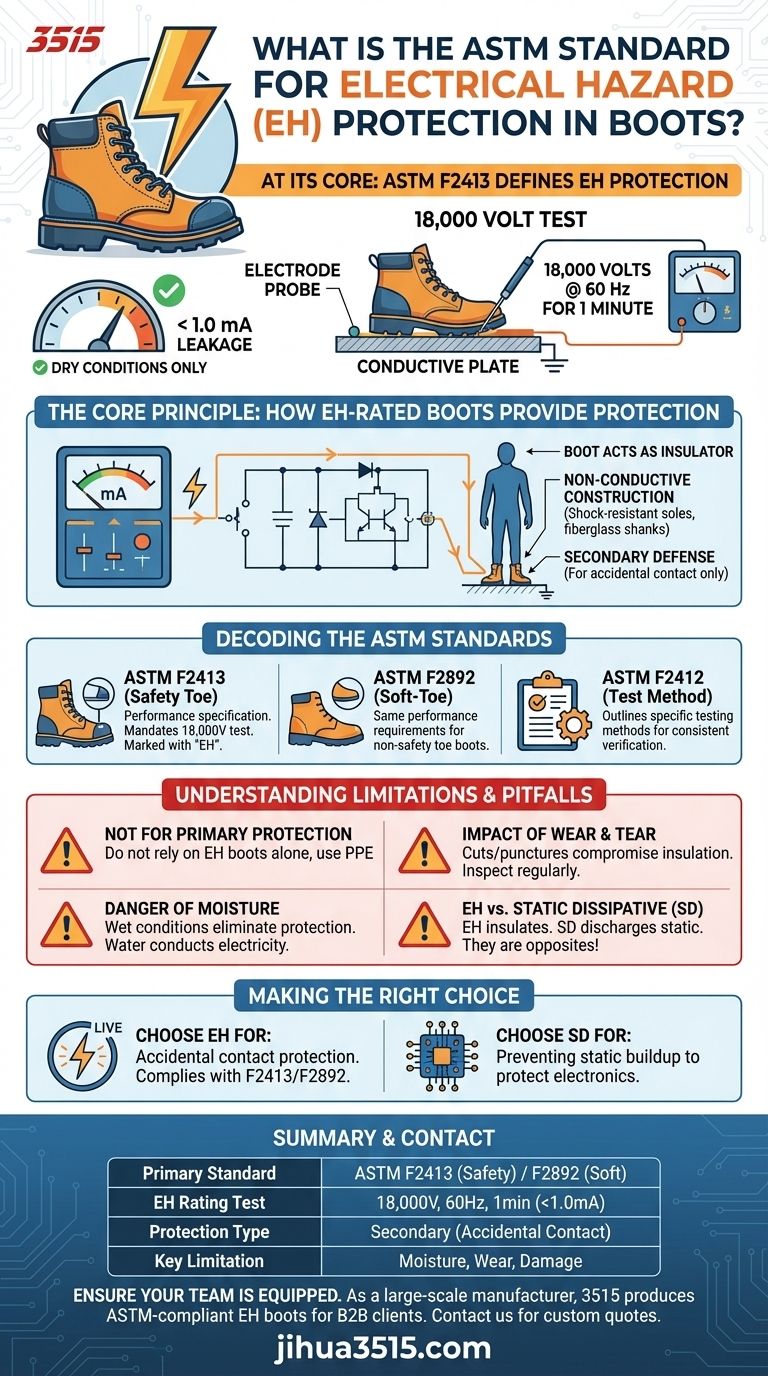

At its core, the standard for electrical hazard protection in footwear is defined by ASTM F2413. This specification requires that a boot must be able to withstand the application of 18,000 volts at 60 hertz for one full minute with no current flow or leakage in excess of 1.0 milliampere under dry conditions.

Electrical Hazard (EH) rated footwear is a critical secondary source of protection, designed to insulate you from the ground and impede your body from completing a circuit during accidental contact with a live electrical conductor.

The Core Principle: How EH-Rated Boots Provide Protection

The primary goal of EH-rated footwear is to prevent the flow of electricity through your body to the ground. This is achieved through specific design and material choices that create a highly resistant barrier.

The Role of Insulation

An EH-rated boot acts as an insulator. By significantly increasing the electrical resistance between your foot and the ground, it helps to stop your body from becoming the path of least resistance for an electrical current.

Non-Conductive Construction

To achieve this insulation, the entire boot is engineered with non-conductive materials. The soles and heels are shock-resistant, and any internal components like the shank must also be made from materials like fiberglass or nylon instead of steel.

A Secondary Line of Defense

It is critical to understand that EH boots are considered secondary protection. They are not a substitute for primary protective equipment (like insulated gloves) or proper safety procedures when working on or near energized circuits. They are designed for accidental contact only.

Decoding the ASTM Standards

The "EH" rating isn't just a marketing term; it signifies that the footwear has passed rigorous, standardized tests. Two key standards govern this process.

ASTM F2413: The Performance Specification

This is the main standard that specifies the minimum performance requirements for protective footwear. For the EH rating, it mandates the 18,000-volt test. Footwear that passes is marked with "EH". This standard applies to footwear with a safety toe cap.

ASTM F2892: The Standard for Soft-Toe Footwear

For protective boots without a safety toe cap, this standard applies. It includes the same performance requirements and testing for electrical hazard protection as ASTM F2413, ensuring consistent safety across different footwear styles.

ASTM F2412: The Test Method

This standard outlines the specific methods for testing protective footwear. It details exactly how the electrical resistance test must be conducted to ensure that any boot claiming an EH rating has been verified under identical, controlled conditions.

Understanding the Limitations and Pitfalls

While EH-rated boots offer a vital layer of safety, their protective capabilities are not absolute. Understanding their limitations is as important as knowing their purpose.

Not for Primary Protection

Never rely on EH boots as your primary means of protection from electric shock. They are a backup system for accidental contact. Always follow established lockout/tagout procedures and use appropriate primary personal protective equipment (PPE).

The Impact of Wear and Tear

The insulating properties of your boots can be compromised over time. Cuts, punctures, and excessive wear can create a path for electricity to travel. Regularly inspect your footwear for any damage to the sole.

The Danger of Moisture

The ASTM test is conducted under dry conditions. Water is an excellent conductor of electricity. If your boots are wet, or if you are standing in water, their ability to protect you is dramatically reduced or eliminated entirely.

EH vs. Static Dissipative (SD)

Do not confuse EH-rated boots with Static Dissipative (SD) footwear. They serve opposite functions. EH boots insulate you from a circuit. SD boots are designed to safely discharge static electricity from your body to the ground to protect sensitive electronic equipment.

Making the Right Choice for Your Goal

Selecting the correct footwear requires a clear understanding of your specific work environment and the hazards you face.

- If your primary focus is protection from accidental contact with live circuits: Choose footwear clearly marked "EH" that complies with either ASTM F2413 (safety toe) or F2892 (soft toe) standards.

- If your primary focus is preventing static buildup to protect sensitive electronics: You need Static Dissipative (SD) footwear, which is functionally the opposite of EH-rated boots.

- If your work environment is frequently wet: Recognize that the effectiveness of EH boots is severely compromised and you must rely entirely on primary safety protocols and equipment.

Ultimately, understanding the specific ASTM rating and its limitations empowers you to make an informed decision that directly enhances your safety on the job.

Summary Table:

| Feature | Key Detail |

|---|---|

| Primary Standard | ASTM F2413 (for safety toe boots) / ASTM F2892 (for soft-toe boots) |

| EH Rating Test | Withstands 18,000 volts, 60 Hz for 1 minute (< 1.0 mA current leakage) |

| Protection Type | Secondary protection against accidental contact with live circuits |

| Key Limitation | Effectiveness is compromised by moisture, wear, and damage |

Ensure your team is equipped with the right safety footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant EH-rated boots for distributors, brand owners, and bulk clients. Our production capabilities ensure durable, non-conductive construction for reliable secondary electrical hazard protection.

Contact us today to discuss your specific needs and receive a custom quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium KPU Injection Athletic Style Safety Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What should contractors look for in work boots? Find the Perfect Blend of Safety, Comfort & Style

- In what scenarios is PU most suitable for work boots? Boost Comfort & Reduce Fatigue for Light-Duty Work

- How do the design and function of western boots differ from work boots? Choosing the Right Footwear for Your Environment

- What are roper boots, and who are they suitable for? Find Your Perfect Work & Casual Footwear

- How do work boots help reduce muscle fatigue? Engineered Support for All-Day Comfort

- What is the significance of safety training with safety boots? Maximizing Protection in High-Risk Zones

- What factors do people commonly consider when choosing work boots? A Guide to Safety, Comfort & Fit

- Are cowboy boots ok for work? A Guide to Professional Style and Workplace Safety