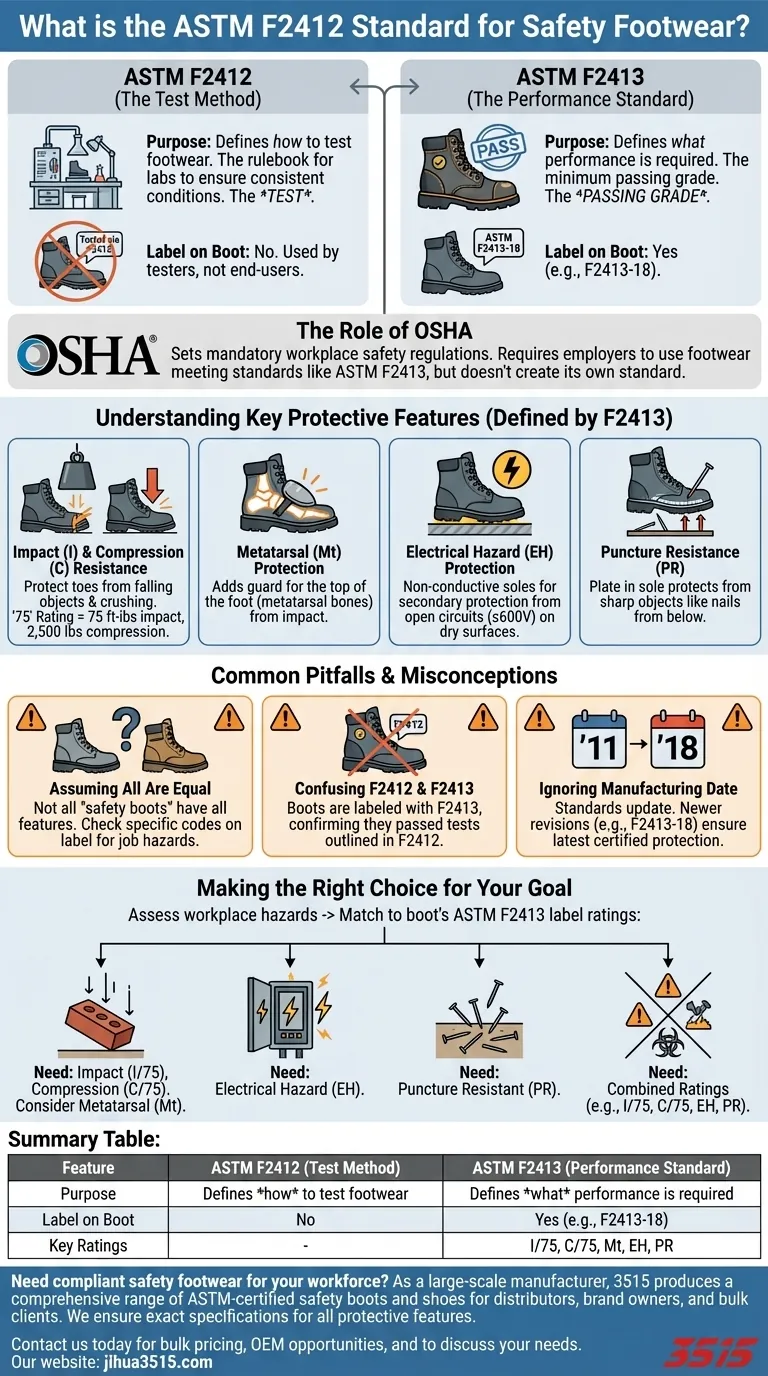

In simple terms, ASTM F2412 is the standard that specifies the methods for testing the performance of protective footwear. It is the "how-to" guide for labs to ensure a safety boot can withstand specific hazards, but it does not set the performance requirements itself. The standard that defines what performance a boot must meet is ASTM F2413.

The core misunderstanding is that ASTM F2412 is the standard for boot performance. Instead, think of it this way: ASTM F2412 defines the test, while ASTM F2413 defines the passing grade. You will find the performance ratings on the boot's label, not the testing method.

Deconstructing Safety Footwear Standards

To select the right footwear, you must understand how the two primary ASTM standards work together. They are separate but interconnected parts of the same safety system.

ASTM F2412: The Test Method Standard

This standard is the rulebook for the laboratory. It outlines the precise procedures, equipment, and protocols for testing safety features.

It ensures that every safety boot is evaluated under the exact same conditions, guaranteeing consistent and repeatable results. You will almost never see F2412 referenced on a boot's tag because it's a standard for the testers, not the end-users.

ASTM F2413: The Performance Requirement Standard

This is the standard that matters most to the user and employer. It specifies the minimum performance requirements a boot must meet to be certified for a particular hazard.

When a boot is labeled "ASTM F2413-18," it signifies that it was tested according to F2412 methods and passed the performance criteria set by F2413. The "-18" indicates the year the standard was last updated (2018).

The Role of OSHA

The Occupational Safety and Health Administration (OSHA) sets the mandatory workplace safety regulations.

OSHA requires employers to ensure workers wear protective footwear in hazardous environments but does not create its own footwear standard. Instead, it defers to and requires footwear that meets standards like ASTM F2413.

Understanding the Key Protective Features

The ASTM F2413 standard covers several distinct types of protection. A boot's label will indicate which of these specific standards it meets.

Impact (I) and Compression (C) Resistance

This is the most fundamental requirement for a safety toe boot. It protects the toes from falling objects and crushing forces.

The rating is almost always "75," which means the toe cap can withstand an impact of 75 foot-pounds and a compressive load of 2,500 pounds.

Metatarsal (Mt) Protection

This feature adds a guard that protects the top of the foot (the metatarsal bones) from impact. It's crucial in environments where objects could drop on the foot, not just the toes.

Electrical Hazard (EH) Protection

EH-rated footwear is designed with non-conductive, shock-resistant soles and heels. It is a secondary source of protection on dry surfaces from open circuits of 600 volts or less.

Puncture Resistance (PR)

This indicates a puncture-resistant plate is built into the sole of the boot to protect the foot from sharp objects like nails or scrap metal from below.

Common Pitfalls and Misconceptions

Understanding the nuances of these standards is critical for ensuring true safety. Simply picking any "safety boot" is a common and dangerous mistake.

Assuming All Safety Boots Are Equal

A boot with only an impact and compression rating offers no protection against electrical shocks or punctures. Always check the specific codes on the label to match the boot's features to the job's hazards.

Confusing F2412 and F2413

As established, F2412 is the test method, and F2413 is the performance specification. A compliant boot will always be labeled with F2413, confirming it passed the tests outlined in F2412.

Ignoring the Manufacturing Date

Standards are updated. The label will show the year of the standard the boot conforms to (e.g., F2413-11 or F2413-18). While older boots may still be acceptable, using footwear that meets the latest revision ensures the highest level of certified protection.

Making the Right Choice for Your Goal

Always start by assessing the specific hazards of your work environment. Then, match those hazards to the ratings on the boot's ASTM F2413 label.

- If your primary focus is protection from falling objects: You need a boot rated for Impact (I/75) and Compression (C/75). Consider Metatarsal (Mt) protection for enhanced safety.

- If your primary focus is working around live circuits: You need a boot specifically rated for Electrical Hazard (EH).

- If your primary focus is preventing sole punctures from below: You need a boot with a Puncture Resistant (PR) plate built into the sole.

- If your primary focus is general compliance in a multi-hazard area: You may need a boot that combines several of these ratings, such as I/75, C/75, EH, and PR.

By understanding the label, you empower yourself to choose the exact protection you need for the job at hand.

Summary Table:

| Feature | ASTM F2412 (Test Method) | ASTM F2413 (Performance Standard) |

|---|---|---|

| Purpose | Defines how to test footwear | Defines what performance is required |

| Label on Boot | No | Yes (e.g., F2413-18) |

| Key Ratings | - | I/75 (Impact), C/75 (Compression), Mt (Metatarsal), EH (Electrical Hazard), PR (Puncture Resistant) |

Need compliant safety footwear for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring you get the exact specifications—from Impact and Compression to Electrical Hazard and Puncture Resistance—that your business requires.

Contact us today for bulk pricing, OEM opportunities, and to discuss your specific safety footwear needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- What does OSHA standard 29 CFR 1910.136(a) require regarding protective footwear? Ensure Compliance & Worker Safety

- What are the different protection levels for safety footwear? A Guide to S1, S3 & More

- What are the two major categories of work-related foot injuries? Protect Your Workforce from Head to Toe

- What advantages do wearable pressure insole systems offer over waist-mounted sensors for fall risk assessment? Discover Precision Safety

- Why is explicit dynamic FEA software necessary for safety shoe toe cap performance? Precision Engineering for Safety

- What is the history of firefighter boots? From Leather to Advanced Protective Systems

- What are the advantages of composite toe caps? Lightweight, Non-Conductive Safety for All-Day Comfort

- What organization sets the standards for safety footwear toe cap performance? ASTM F2413 Explained