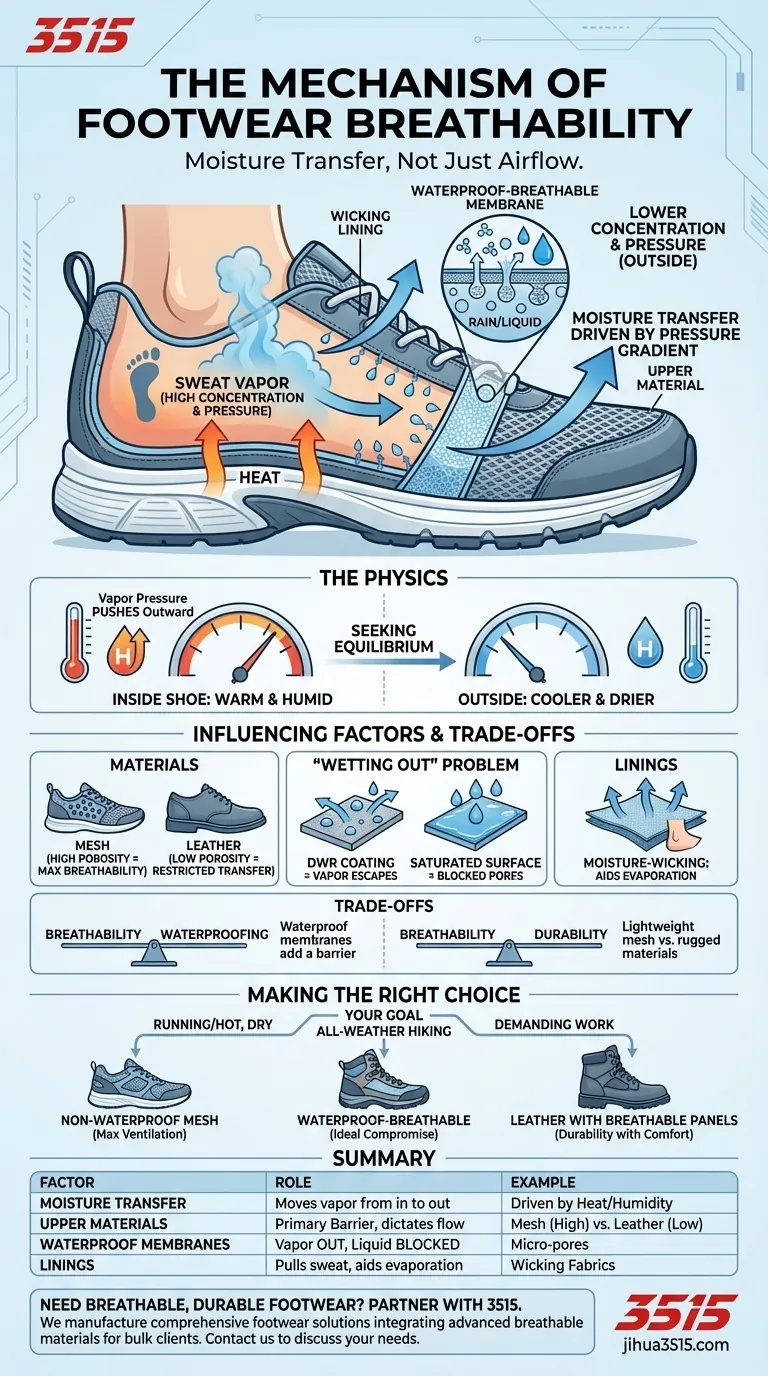

At its core, the mechanism of breathability in footwear is a physical process of moisture transfer. It is not about airflow in the conventional sense, but about moving water vapor—your sweat—from an area of high concentration and pressure inside the shoe to an area of lower concentration and pressure outside. This process is driven by the natural tendency of systems to seek equilibrium.

The crucial insight is that "breathability" is less about letting air in and more about actively pushing moisture out. This is achieved through a pressure gradient created by the heat and humidity your foot generates inside the shoe.

The Physics of Moisture Transfer

To truly understand breathability, you have to think about the environment inside your shoe versus the environment outside.

The Role of Concentration Gradients

Your foot constantly releases moisture as water vapor. This creates a warm, humid microclimate inside your shoe with a high concentration of water vapor molecules.

The air outside the shoe typically has a lower concentration of water vapor. This difference, or gradient, causes moisture to naturally move from the inside to the outside to balance the concentration.

The Importance of Temperature

The heat generated by your foot is a critical engine for this process. Warmer air can hold more moisture and has a higher vapor pressure.

This increased pressure inside the shoe literally pushes the water vapor molecules outward through the shoe's material, accelerating the transfer process.

How Waterproof Membranes Breathe

Materials like GORE-TEX utilize a clever engineering solution to be both waterproof and breathable. The membrane is filled with microscopic pores.

These pores are thousands of times larger than a single water vapor molecule, allowing sweat to easily escape. However, they are significantly smaller than a liquid water droplet, preventing rain or puddle water from getting in.

Key Factors Influencing Shoe Breathability

The theoretical mechanism is only effective if the shoe's construction allows it to happen. Several factors can help or hinder this process.

Upper Materials

The outer material of the shoe has the single biggest impact. Synthetic mesh materials are extremely porous and offer maximum breathability.

Conversely, materials like full-grain leather are much denser and less permeable, significantly restricting the escape of moisture.

The Problem of "Wetting Out"

Even a shoe with a GORE-TEX membrane can lose its breathability if the outer fabric becomes saturated with water.

This creates a continuous film of water on the exterior, blocking the pores and trapping water vapor inside. This is why many high-end shoes use a Durable Water Repellent (DWR) finish to make water bead up and roll off the surface.

Linings and Internal Construction

Internal moisture-wicking linings play a supporting role. They pull sweat away from your skin and spread it over a larger surface area, which helps it evaporate more efficiently and begin its journey to the outside.

Understanding the Trade-offs

Choosing footwear is always a balancing act. No single shoe has perfect breathability, durability, and protection.

Breathability vs. Waterproofing

There is an inherent trade-off here. A fully waterproof shoe will never be as breathable as a non-waterproof shoe with an open mesh design. The waterproof membrane is one more barrier that water vapor must pass through.

Breathability vs. Durability

The most breathable materials, like lightweight mesh, are often less resistant to abrasion and wear than rugged materials like leather. You must choose based on your intended activity and environment.

Making the Right Choice for Your Goal

Selecting the right footwear depends entirely on your specific needs and the conditions you expect to face.

- If your primary focus is running or walking in hot, dry weather: Prioritize non-waterproof shoes with large synthetic mesh panels for maximum ventilation.

- If your primary focus is all-weather hiking and backpacking: A shoe with a waterproof-breathable membrane is the ideal compromise for keeping feet dry from both rain and sweat.

- If your primary focus is durability for demanding work: Leather boots are often necessary, but look for models that incorporate breathable fabric panels or moisture-wicking liners to mitigate heat and sweat buildup.

Ultimately, understanding how breathability works empowers you to select footwear that keeps you dry, comfortable, and blister-free.

Summary Table:

| Factor | Role in Breathability | Key Example |

|---|---|---|

| Moisture Transfer | Core mechanism moving water vapor from inside to outside | Driven by heat and humidity from the foot |

| Upper Materials | Primary barrier; porosity dictates breathability level | Synthetic mesh (high) vs. full-grain leather (low) |

| Waterproof Membranes | Allows vapor out but blocks liquid water in via microscopic pores | GORE-TEX |

| Linings | Pulls sweat from skin to aid evaporation and transfer | Moisture-wicking fabrics |

| Trade-offs | Breathability is balanced against waterproofing and durability | Waterproof shoes are less breathable than mesh shoes |

Need breathable, durable footwear for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, integrating advanced breathable materials and moisture-wicking technologies to ensure superior comfort.

Let's collaborate to create the perfect footwear solution for your market. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

People Also Ask

- How should you polish cowboy boots for the best results? A Pro Guide to a Perfect Shine

- Why is the systematic distribution of PPE essential in construction? Secure Your Site with Pre-Deployment Safety

- What is the primary purpose of using Ecoflex or silicone for sensor encapsulation? Durable Protection for Smart Footwear

- Why is low-pressure steam plasma pretreatment used? Unlock Superhydrophobic Durability for Specialty Footwear Fabrics

- Why is the application of advanced 3D modeling software necessary for the production of customized foot gear? Learn How

- How do industrial-grade isokinetic dynamometer systems assess athletic footwear? Precision Muscle Power Testing

- How does the implementation of a fixed visual target standardize the testing environment for footwear balance evaluation?

- How do integrated IMU sensors function in smart assistive footwear? Master Real-Time Motion Monitoring