Direct attach construction is a modern boot-making method where the outsole is molded directly to the upper fabric of the boot. This process forms an incredibly strong, seamless, and often waterproof bond without relying solely on glues or traditional stitching to hold the boot together.

The choice of boot construction is a critical trade-off between durability, flexibility, and repairability. Direct attach offers a superior bond for durability and water resistance compared to simpler methods, but it's important to understand how it fits into the broader landscape of boot design.

How Boot Construction Defines Performance

The method used to join a boot's upper (the part that covers your foot) to its outsole (the part that hits the ground) is fundamental to its performance. This single factor influences everything from how long the boot lasts to how it feels after a ten-hour day.

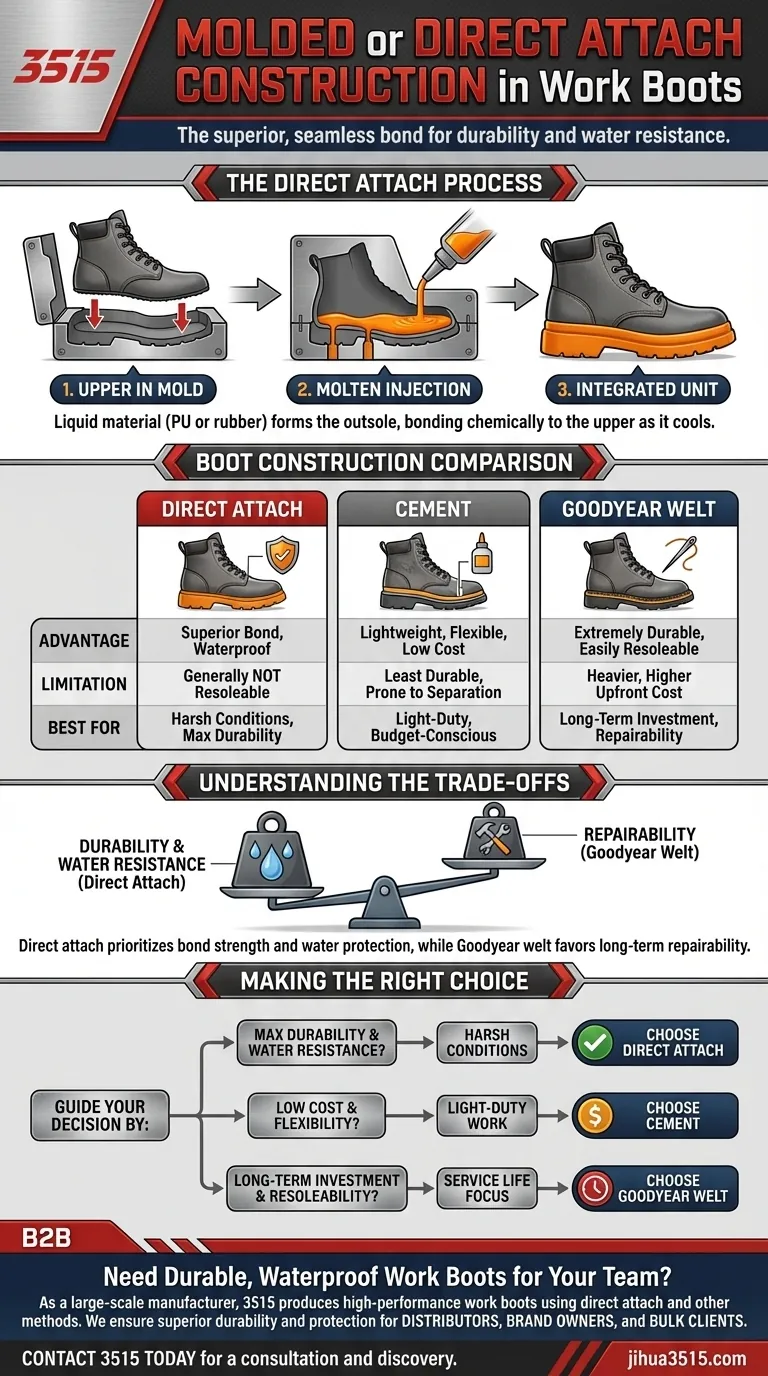

The Direct Attach Process

In direct attach, or molded, construction, the boot's upper is placed into a specialized mold. Molten material, typically polyurethane or rubber, is then injected into the mold.

This liquid material flows and forms the outsole, bonding permanently and chemically to the upper as it cools and hardens.

The result is a single, integrated unit. There are no stitches or glue lines at the seam, creating a powerful and resilient connection.

How It Compares to Other Methods

To understand the value of direct attach, it helps to compare it to the two other common methods.

Cement construction is the simplest method, where the outsole is attached to the upper using a strong adhesive. This makes for a lightweight and flexible boot but is the least durable option.

Goodyear welt construction is a traditional method where a strip of leather (the welt) is stitched to both the upper and the outsole. This is extremely durable, water-resistant, and allows the boot to be resoled multiple times.

Understanding the Trade-offs

No single construction method is perfect for every application. Choosing the right one requires understanding the inherent compromises.

The Primary Advantage: A Superior Bond

The primary benefit of direct attach construction is the strength of the bond. Because the sole and upper become one piece, the risk of sole separation, or "delamination," is dramatically reduced compared to cemented boots.

The Secondary Benefit: Water Resistance

The seamless nature of the molded bond is a significant advantage in wet environments. Without traditional stitching holes connecting the sole, there are far fewer potential entry points for water to seep in.

The Key Limitation: Repairability

The main drawback of direct attach construction is that the boots are generally not resoleable. Because the outsole is molded to the upper, it cannot be replaced when it wears out.

This contrasts sharply with Goodyear welted boots, which are designed to be resoled repeatedly, extending their service life considerably.

Making the Right Choice for Your Work

Your decision should be guided by your daily work environment, your budget, and how you value long-term repairability.

- If your primary focus is maximum durability and water resistance for harsh conditions: Direct attach provides an excellent, long-lasting bond that prevents sole separation and keeps feet dry.

- If your primary focus is the lowest cost and high flexibility for light-duty work: A simpler cement construction is often sufficient and more affordable, though less durable over time.

- If your primary focus is a long-term investment and the ability to resole your boots: The traditional Goodyear welt construction, while often heavier and more expensive upfront, is the definitive choice for service life.

Understanding the construction method empowers you to select a boot that performs as a reliable and appropriate tool for your specific job.

Summary Table:

| Construction Method | Primary Advantage | Key Limitation | Best For |

|---|---|---|---|

| Direct Attach | Superior, seamless bond; Excellent water resistance | Generally not resoleable | Harsh conditions, maximum durability, wet environments |

| Cement | Lightweight, flexible, low cost | Least durable; prone to sole separation | Light-duty work, budget-conscious buyers |

| Goodyear Welt | Extremely durable; easily resolable | Heavier, higher upfront cost | Long-term investment, repairability |

Need Durable, Waterproof Work Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance work boots using direct attach and other construction methods. We ensure superior durability and waterproof protection for distributors, brand owners, and bulk clients.

Let us help you select or manufacture the perfect footwear for your specific job requirements.

Contact 3515 today for a consultation and discover how our production capabilities can meet your needs.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the key roles of work boots in labor-intensive jobs? Essential for Safety, Performance & Comfort

- What makes engineer boots suitable for motorcycle riding? Classic Style Meets Core Protection

- What features should workers exposed to chemicals look for in work boots? Essential Guide for Safety

- What are the key characteristics of wildland firefighter boots? Essential Gear for Extreme Conditions

- What features should construction and industrial work boots have? Essential Safety & Protection Guide

- What are the advantages of using snowshoeing boots for winter biking? Unbeatable Warmth & Value on Flat Pedals

- Is there a definitive answer to whether pull-on or lace-up work boots are better? Choose the Right Boot for Your Job

- How do structural firefighting boots protect against debris and sharp objects? | Complete Foot Safety Guide