In high-quality footwear, the Goodyear welt is the gold standard for durability and repairability. It is a traditional shoe construction method where a strip of leather, known as the "welt," is stitched to the shoe's upper and a canvas rib on the insole. A second, separate stitch then attaches the outsole to this welt. This two-level stitching process creates an incredibly robust shoe that can be resoled multiple times without damaging its core structure.

The Goodyear welt is more than a construction method; it's a structural philosophy. By creating an indirect connection between the sole and the upper, it makes the shoe exceptionally durable and, most importantly, repairable, turning a purchase into a long-term investment.

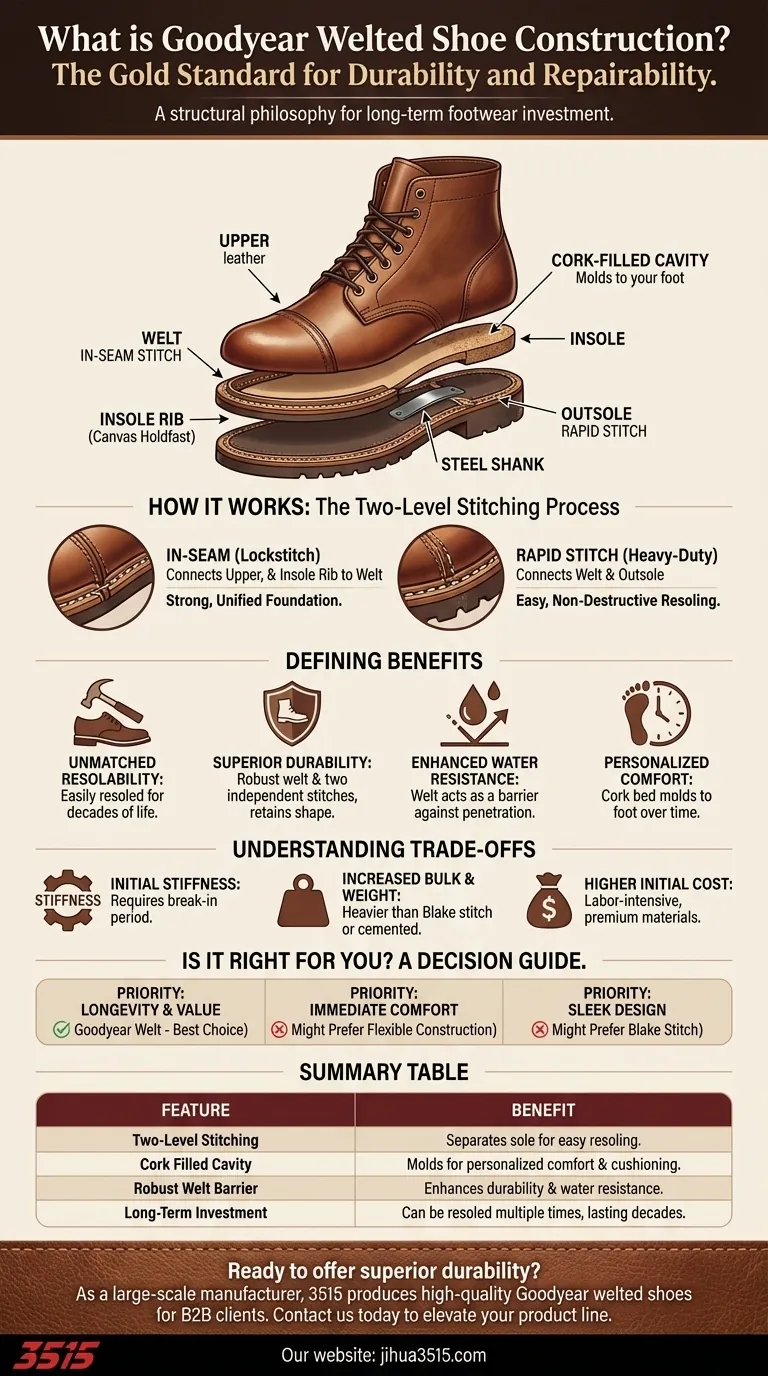

How Goodyear Welt Construction Works

Understanding the Goodyear welt requires looking at the key components and the specific stitching process that sets it apart.

The Core Components

At the heart of the construction are the insole, the upper, the welt, and the outsole. A canvas rib, or "holdfast," is first cemented to the perimeter of the insole, providing a sturdy anchor point for the initial stitches.

The Two-Level Stitching

First, an "in-seam" stitch (a Lockstitch) passes through the upper, the lining, and the insole rib, attaching the welt around the outside edge of the shoe. This creates a strong, unified foundation.

The outsole is then attached with a separate, heavy-duty "rapid stitch" that goes only through the welt and the outsole. Because this stitch never penetrates the insole, it can be cut and replaced by a cobbler without disturbing the shoe's upper.

The Cork-Filled Cavity

The space between the insole and the outsole, enclosed by the welt, is filled with a layer of granulated cork. This cork filling provides cushioning, insulation, and breathability. Over time, it compresses and molds to the shape of your foot, creating a personalized fit.

The Defining Benefits of a Goodyear Welt

The complexity of this construction method delivers several distinct advantages that define premium footwear.

Unmatched Resolability

This is the primary benefit. Since the outsole is stitched to the welt and not directly to the upper, a cobbler can easily remove the old sole and stitch on a new one. This allows a well-cared-for pair of shoes to last for decades.

Superior Durability

The combination of the robust welt and the two independent, heavy-duty stitches creates a shoe that is exceptionally strong and resilient. The structure also includes a metal shank in the arch to ensure the shoe retains its shape over years of wear.

Enhanced Water Resistance

The welt acts as a barrier between the upper and the outsole, making it significantly more difficult for water to penetrate the shoe from the ground up compared to simpler construction methods.

Personalized Comfort Over Time

While initially stiff, the cork footbed gradually molds to the unique contours of your foot with every step. This process creates a custom-like insole that provides unparalleled support and comfort for the life of the shoe.

Understanding the Trade-offs

No construction method is perfect for every situation. Objectivity requires acknowledging the compromises inherent in a Goodyear welt.

Initial Stiffness

Goodyear welted shoes are known for their initial rigidity. The multiple layers and strong construction require a "break-in" period for the leather and cork to soften and conform to your foot.

Increased Bulk and Weight

The additional materials and layers, including the welt itself, result in a shoe that is typically heavier and less flexible than those made with a Blake stitch or cemented construction. This can make them feel less sleek.

Higher Initial Cost

The Goodyear welting process is labor-intensive and requires skilled craftsmanship and more raw materials. This complexity is directly reflected in a higher purchase price compared to mass-market footwear.

Is a Goodyear Welted Shoe Right for You?

Choosing the right shoe construction depends entirely on your priorities.

- If your primary focus is longevity and value: A Goodyear welt is the best choice, as the ability to resole the shoe makes it a worthwhile long-term investment.

- If your primary focus is immediate, out-of-the-box comfort: You might find the break-in period challenging and may prefer a more flexible construction.

- If your primary focus is a sleek, low-profile design: The inherent bulk of the Goodyear welt may not align with your aesthetic, and a Blake-stitched shoe might be a better fit.

Ultimately, understanding the Goodyear welt allows you to invest not just in a pair of shoes, but in footwear built to last a lifetime.

Summary Table:

| Feature | Benefit |

|---|---|

| Two-Level Stitching | Separates the sole from the upper for easy, non-destructive resoling. |

| Cork Filled Cavity | Molds to your foot for personalized comfort and provides cushioning. |

| Robust Welt Barrier | Enhances durability and water resistance, protecting the shoe's core. |

| Long-Term Investment | Can be resoled multiple times, extending the shoe's life for decades. |

Ready to offer your customers the superior durability of Goodyear welted footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality Goodyear welted shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, repairable footwear built to last.

Contact us today to discuss your manufacturing needs and elevate your product line.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Heavy-Duty Goodyear Welted Pull-On Safety Rigger Boot

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

People Also Ask

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality

- What causes white marks on rubber boots, and how can they be removed? A Guide to 'Blooming' & Boot Care