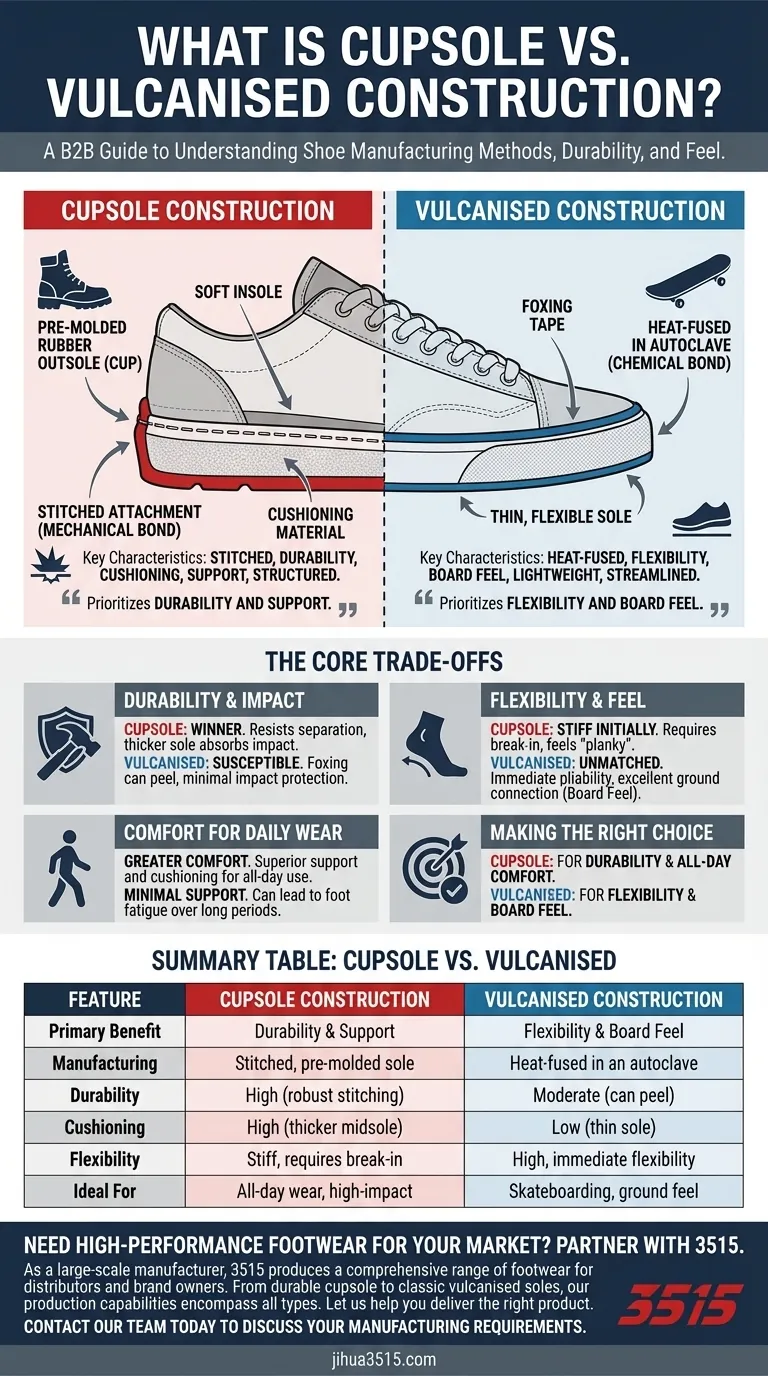

At its core, cupsole construction is a method of attaching the sole to a shoe's upper using stitching. A pre-molded rubber outsole, shaped like a "cup," is physically stitched to the upper, creating a durable and supportive final product. This stands in direct contrast to vulcanised construction, where the rubber sole components are heat-fused directly onto the upper in a large oven, resulting in a more flexible but often less cushioned shoe.

The choice between cupsole and vulcanised footwear is not about which is superior, but about a fundamental trade-off: cupsoles prioritize durability and support, while vulcanised soles prioritize flexibility and board feel.

Deconstructing the Cupsole

The Manufacturing Process

A cupsole is a pre-formed, single piece of rubber that includes the outsole and the sidewalls. This "cup" is filled with cushioning material and a soft insole.

The shoe's upper is then placed inside this cup, and the two components are secured together with a durable stitch that runs around the entire perimeter of the shoe. This creates a strong, mechanical bond.

Key Characteristics

The primary benefit of this construction is durability. The thick rubber sole and robust stitching can withstand significant wear and tear, making cupsoles a long-lasting option.

This method also allows for more substantial midsoles and insoles, providing superior cushioning and impact protection. This makes them exceptionally comfortable for all-day wear and walking.

Aesthetically, cupsoles often result in a slightly bulkier or more "structured" silhouette compared to the slim profile of their vulcanised counterparts.

Understanding Vulcanised Construction

The "Baking" Process

Vulcanised construction uses a chemical process involving heat and pressure. The shoe's upper has its outsole components attached with a strip of rubber tape called foxing.

The entire shoe is then heated in a special oven, or autoclave. This process melts and fuses the rubber components into a single, cohesive, and pliable unit bonded directly to the upper.

Key Characteristics

The defining feature of a vulcanised shoe is its flexibility. The heat-fused sole is thin and highly pliable, offering an excellent connection to the ground or a skateboard.

This is often referred to as "board feel" in the skate community, as it allows the rider to make micro-adjustments with their feet. They typically require almost no break-in period.

The simpler construction generally results in a lighter-weight shoe with a classic, slim, and streamlined look.

The Core Trade-offs: Support vs. Feel

Durability and Impact Protection

Cupsoles are the clear winner for durability and impact absorption. The stitched construction is less likely to separate, and the thicker sole provides more cushioning against hard surfaces.

Vulcanised shoes are more susceptible to the foxing tape peeling away from the upper with heavy use, and their thin soles offer minimal impact protection.

Flexibility and Board Feel

Vulcanised construction is unmatched in flexibility. This pliability is essential for activities like skateboarding, where a direct feel for the board is critical for control and performing tricks.

Cupsoles, by contrast, can feel stiff and "planky" out of the box. They often require a significant break-in period before the sole gains some flexibility.

Comfort for Daily Wear

For general, all-day use that involves a lot of walking or standing, cupsoles typically offer greater comfort due to their superior support and cushioning.

While vulcanised shoes are light, their minimal support can lead to foot fatigue over extended periods of walking on hard surfaces.

Making the Right Choice for Your Needs

Choosing between these two methods depends entirely on your primary goal for the footwear.

- If your primary focus is durability and all-day comfort: Choose a cupsole for its superior support, impact protection, and long-lasting construction.

- If your primary focus is flexibility and board feel: Choose a vulcanised shoe for its immediate comfort, light weight, and unparalleled ground connection.

- If your primary focus is impact protection for skating: Modern skate-focused cupsoles offer a hybrid approach, providing the necessary durability and cushioning for high-impact tricks.

Understanding this fundamental difference in construction empowers you to choose footwear based on performance and purpose, not just style.

Summary Table:

| Feature | Cupsole Construction | Vulcanised Construction |

|---|---|---|

| Primary Benefit | Durability & Support | Flexibility & Board Feel |

| Manufacturing | Stitched, pre-molded sole | Heat-fused in an autoclave |

| Durability | High (robust stitching) | Moderate (can peel) |

| Cushioning | High (thicker midsole) | Low (thin sole) |

| Flexibility | Stiff, requires break-in | High, immediate flexibility |

| Ideal For | All-day wear, high-impact | Skateboarding, ground feel |

Need High-Performance Footwear for Your Market? Partner with 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Whether your customers demand the durable support of cupsole construction or the classic flexibility of vulcanised soles, our production capabilities encompass all types of shoes and boots.

Let us help you deliver the right product for every need. Contact our team today to discuss your manufacturing requirements.

Visual Guide

Related Products

- Wholesale Lightweight Cushioned Athletic Sneakers for Custom Bulk Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Lightweight Breathable Sneakers with Wet-Traction Grip for Wholesale & Private Label

People Also Ask

- What role does wireless data transmission play in gait analysis? Unlock Real-World Mobility Insights

- How do safety harnesses assist in high-intensity treadmill testing? Ensure Data Validity for High-Performance Footwear

- Why is the use of standardized Running Shoes essential for static balance testing? Ensure High-Fidelity Data Accuracy

- Are running shoes suitable for walking? Discover the Surprising Cushioning Benefits

- What are the benefits of wearing proper athletic footwear? Enhance Performance & Prevent Injury